Subsection-studding all-open-stoping backfilling collaborative mining method

A mining method and open field technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve problems such as the inability to guarantee the safety of construction workers, difficulty in mining top pillars, and waste of mineral resources, so as to improve the degree of safety assurance , high ore recovery rate, and the effect of ensuring mining safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

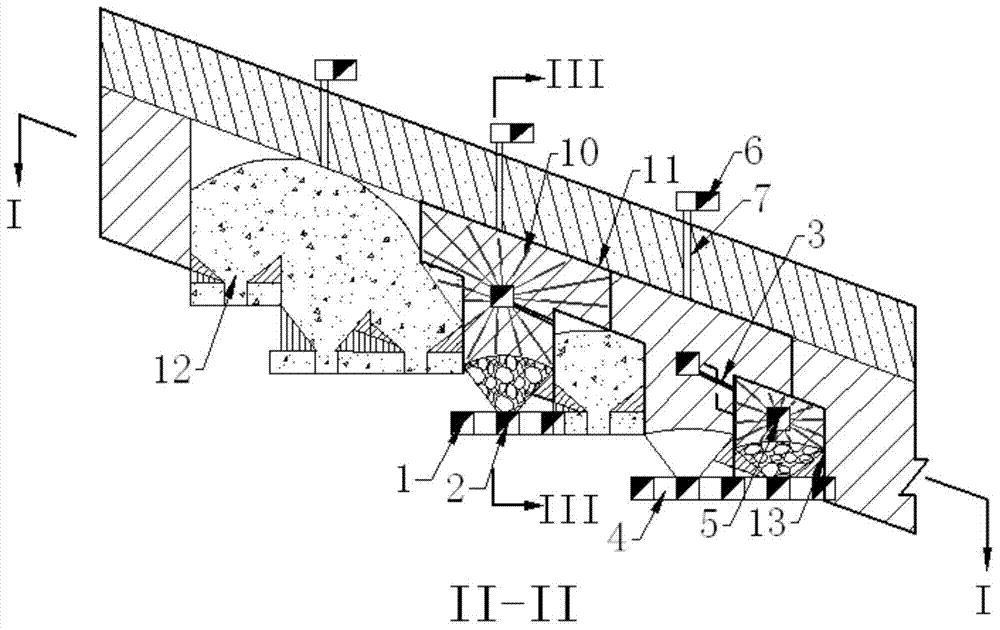

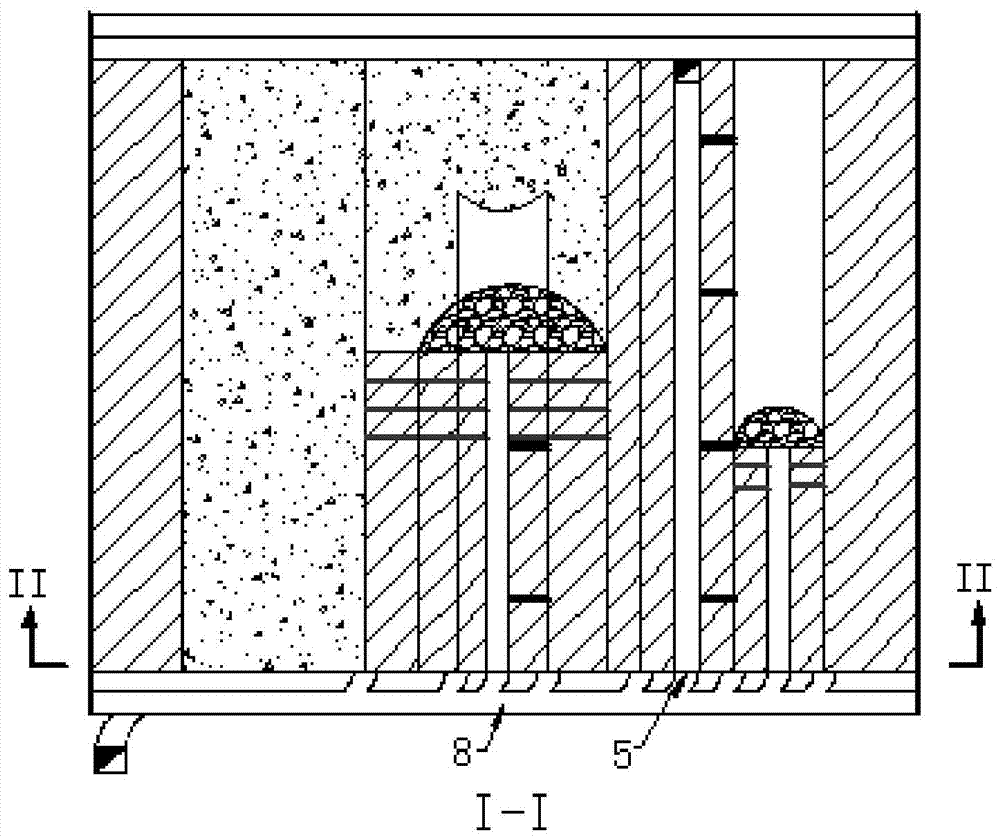

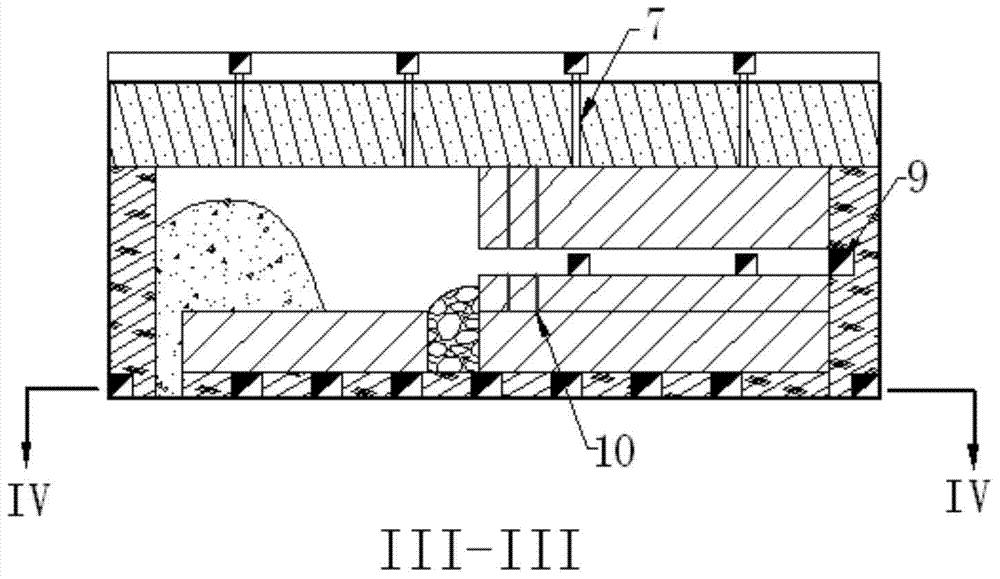

[0029] see figure 1 , figure 2 , image 3 and Figure 4 , in the figure: 1- mining roadway; 2- bottom roadway; 3, 6- filling roadway; stope contact road; 10-blasting hole; 11-filling body.

[0030] The ore body is divided into different panels along the strike by panel tunnels, with a panel width of 80 meters and a panel column of 12 meters. The stope is arranged along the inclination in the panel area, the length of the stope is 80 meters, the width is 12 meters, and the height is the full thickness of the ore body. Adopting a retreat mining scheme of mining one at a time, the goaf is filled to realize goaf treatment and ground pressure control, and a 3×3 m rock drilling roadway is excavated in the center of the bottom of the stope, and in the peach-shaped ore pillars on both sides of the rock drilling roadway Two out-of-mine roadways are arranged, and the out-of-mine river is excavated to the rock-drilling roadway in a staggered manner, and finally the mining quasi-wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com