Method for exploiting gently-inclined thin-to-medium-thickness ore bodies

A mining method and thick ore body technology, applied in ground mining, earth square drilling, underground mining, etc., can solve the problems of large ore loss, high labor productivity, and small mining workload, and achieve the effect of overcoming pipeline filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

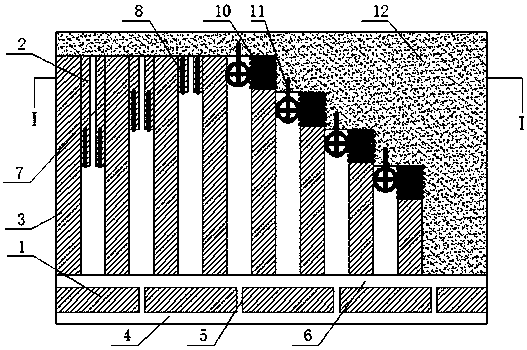

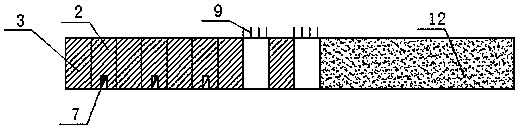

[0022] A lead-zinc mine in Northwest China is an exhalation-type lead-zinc deposit with sedimentary rock as the host rock. The ore body is layered, layered, or convex mirror-shaped, with an average dip angle of 10° and a thickness of 3-8m. The room-and-pillar mining method of the present invention is adopted. method for mining, panel layout and structure such as figure 1 and figure 2 As shown, the specific working steps are as follows:

[0023] A. Panel setting: the ore body is divided into panel areas, the panel area is 100m wide along the strike, and 80m long along the inclination. The ore pillar 3 is arranged in equal width, the width of the mine room 2 and the ore pillar 3 is 6m, and the thickness of the bottom pillar 1 is 10m;

[0024] B. Mining and cutting: the panel transport lane 4 passes through the connecting lane 5 arranged in the bottom column 1 to excavate the cutting drift 6 above the bottom pillar 1, the height of the cutting drift 6 is equal to the thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com