Medium-length-hole room-and-pillar method of synchronically forming barrier pillars

A fan-shaped medium-deep hole and ore pillar technology, which is applied in ground mining, underground mining, special mining, etc., can solve the problems of high ceiling in the stope, inability of ore to slide by itself, and difficulty in roof management, so as to achieve large production capacity and shorten the production time. The recovery cycle and the effect of improving the ore recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

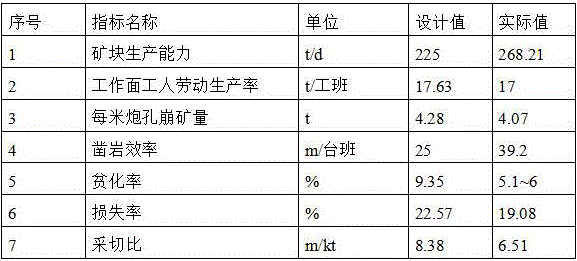

Embodiment 1

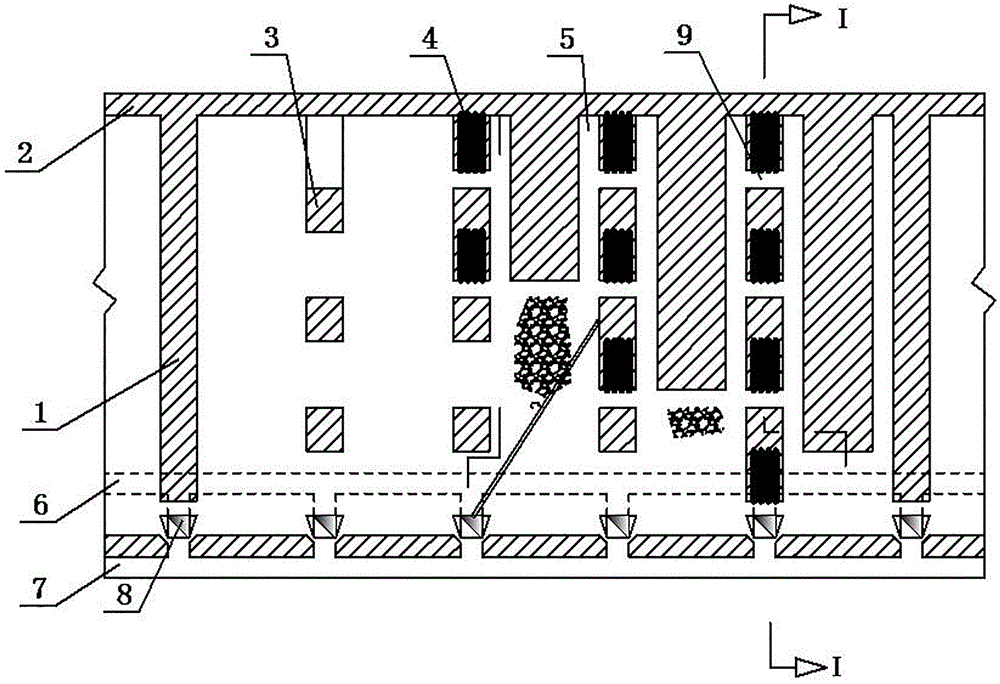

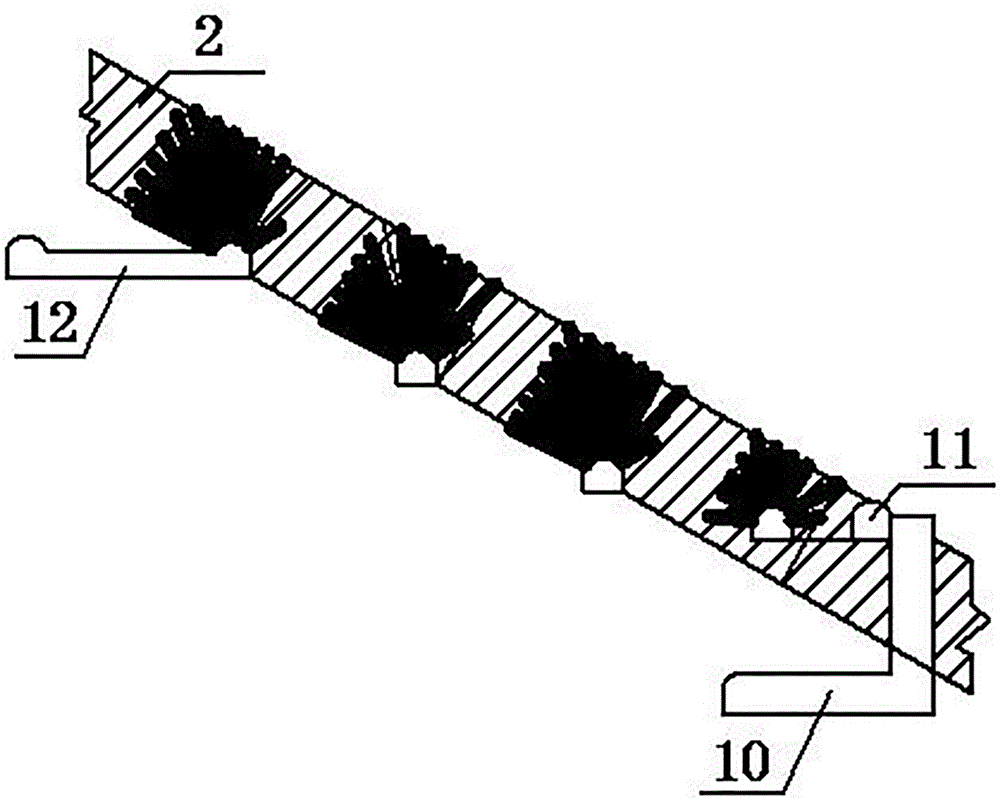

[0020] A phosphate mine is a national key construction project. The mine has successively tested the inclined fan-shaped medium-deep hole room-and-pillar mining method, the gently inclined segmented open field method, and the medium-deep hole room-and-pillar method of the present invention that synchronously forms spaced pillars. The orebody dip angle of the test site is 35~39°, the thickness is 10~11m, and the hardness coefficient is 8~12. 5m wide continuous ore pillar 1, one ore block is arranged every 20m in the panel; in the ore block, the span of the mine room is 15m, the width of the interval pillar 3 is 5m, and the size of the interval pillar 3 is 5×6~5×8m , the top column 2 is 3m thick, and the vertical height of the bottom structure is 8~12m.

[0021] The mining and cutting work of this mine is as follows: a, transport level roadway 7 is arranged in the surrounding rock of the ore body floor, excavates a mine shaft 8 from the transport level roadway 7 to each ore bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com