House pillar changeable panel upward demix filling mining method

A backfill mining method and transforming technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of lack of support means, increase of resource loss rate, damage stability of ore pillar and rock mass, etc., to improve the integrity and stability, improve resource recovery rate, improve the effect of overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The mining area directly under the Sanshandao Gold Mine is an underground gold mine with a large production scale in my country, with a production capacity of 3500t / d. The ore body strikes 62°, dips southeast, dips from 33° to 67°, with an average of 46°, and the dip tends to become steeper from north to south. The ore body is 20-30m thick, 60m locally, and the maximum horizontal thickness is nearly 100m. The ore grade is 1.52-12.53g / t, with an average of 3.26g / t. At present, the ore bodies below the middle section of -565m are mainly mined.

[0036] The specific implementation steps are:

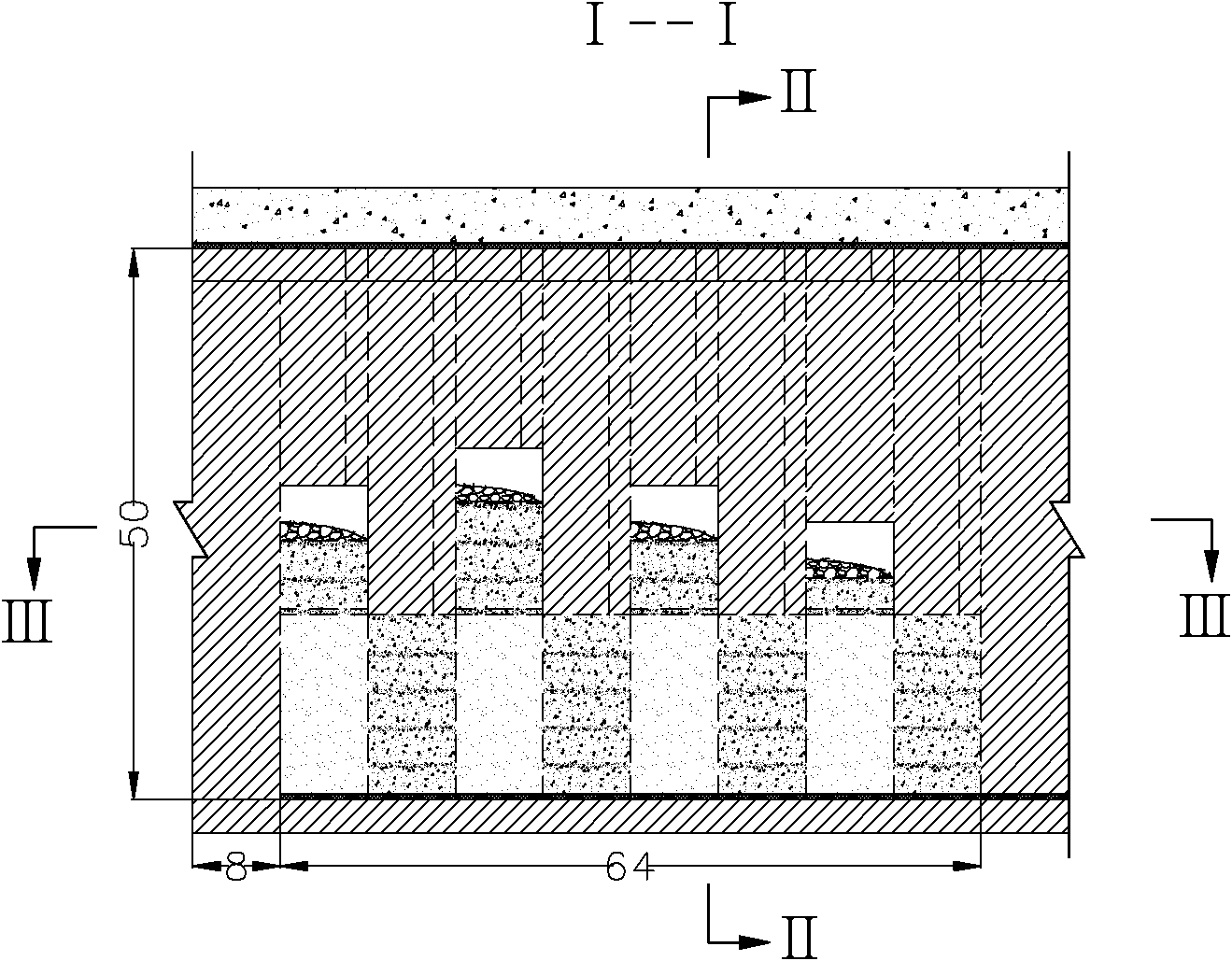

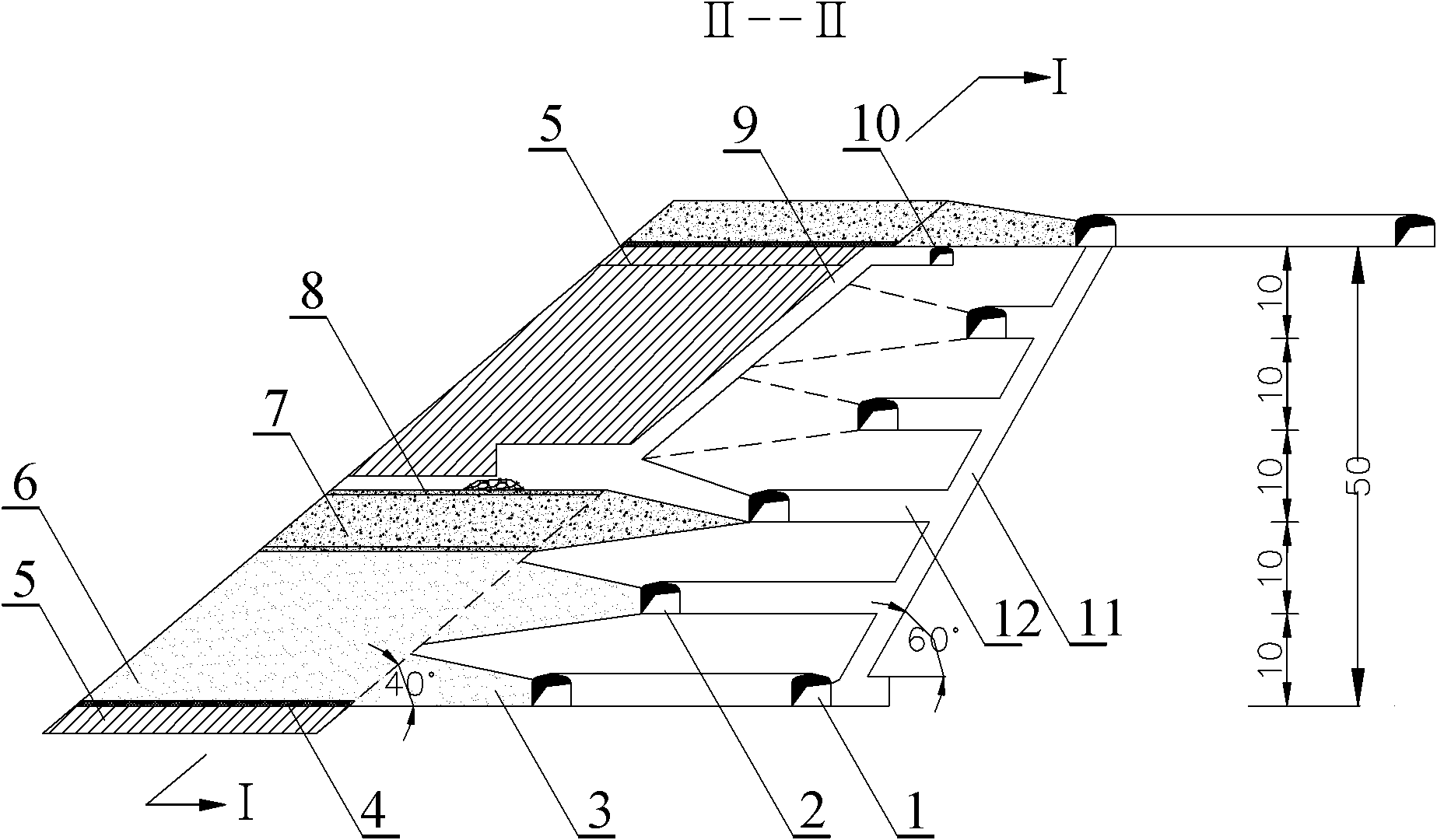

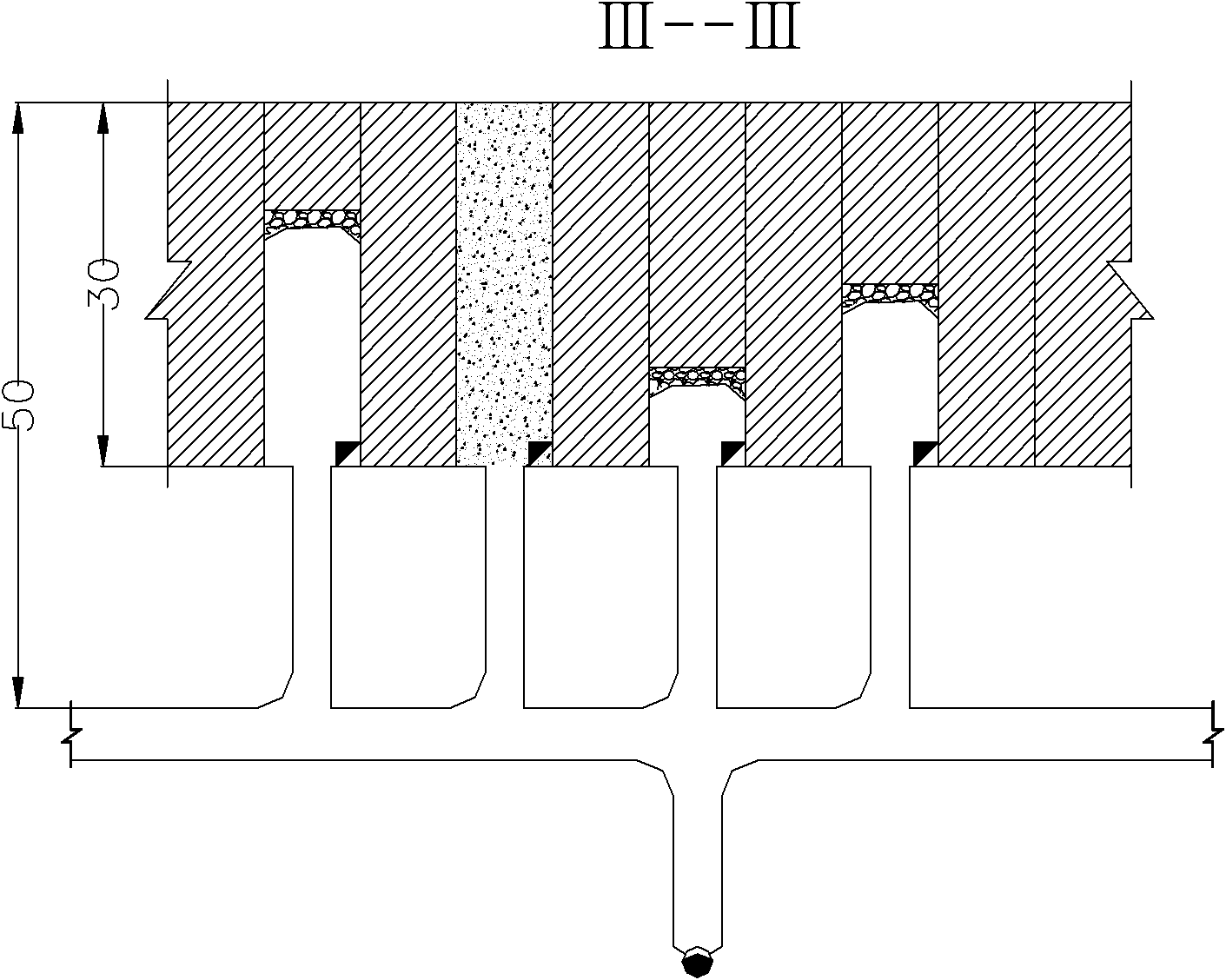

[0037]①In the middle section of -565m~-625m directly under the Sanshandao Gold Mine, the dip angle of the ore body is 35~45°, and the horizontal thickness of the ore body is more than 30m. Mine houses and pillars are arranged at intervals, with a width of 8m. Eight mine pillars form a panel with a length of 64m. The middle section is 50m high.

[0038] ② The mine adopts the devel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com