Patents

Literature

43results about How to "Guaranteed safe recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

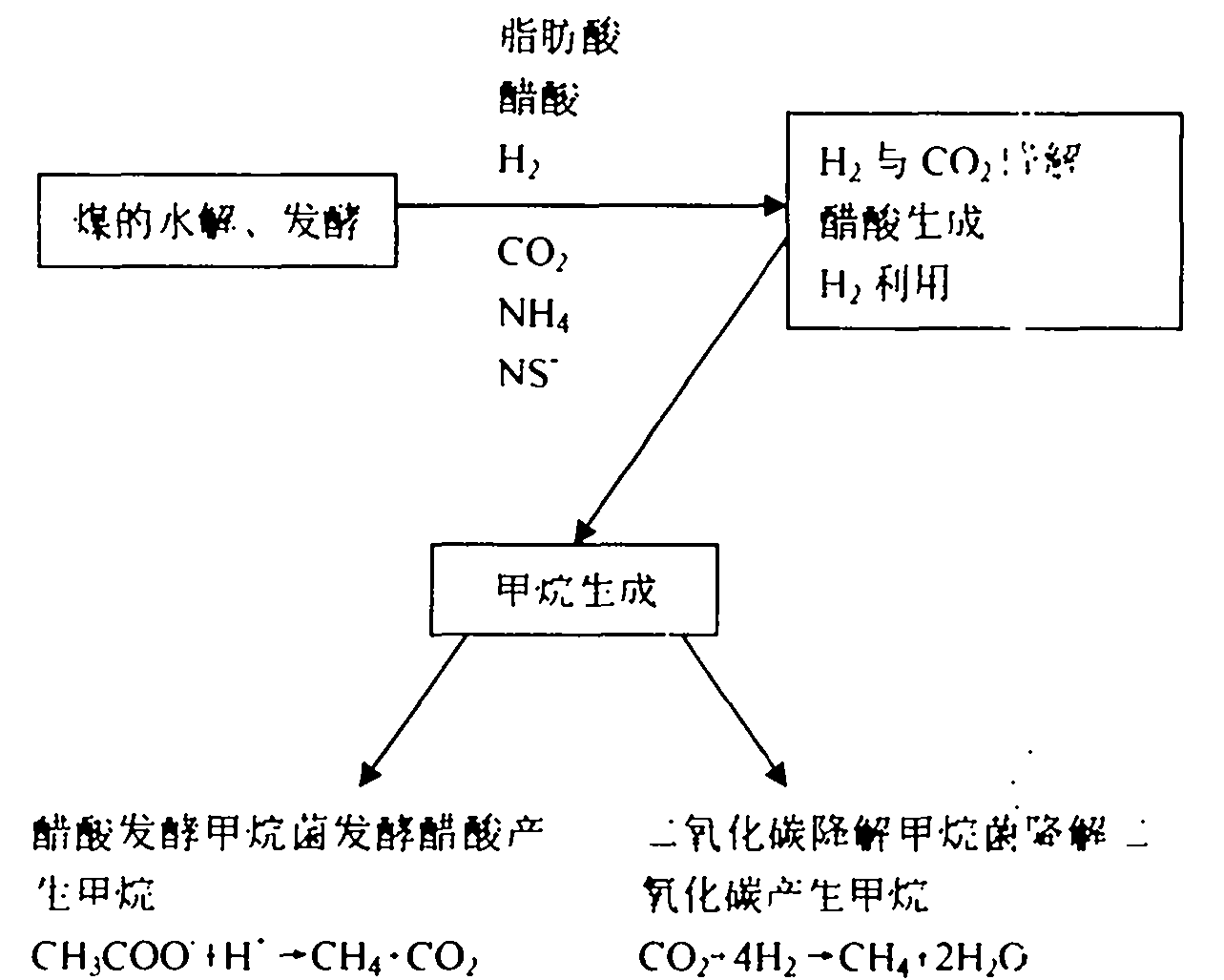

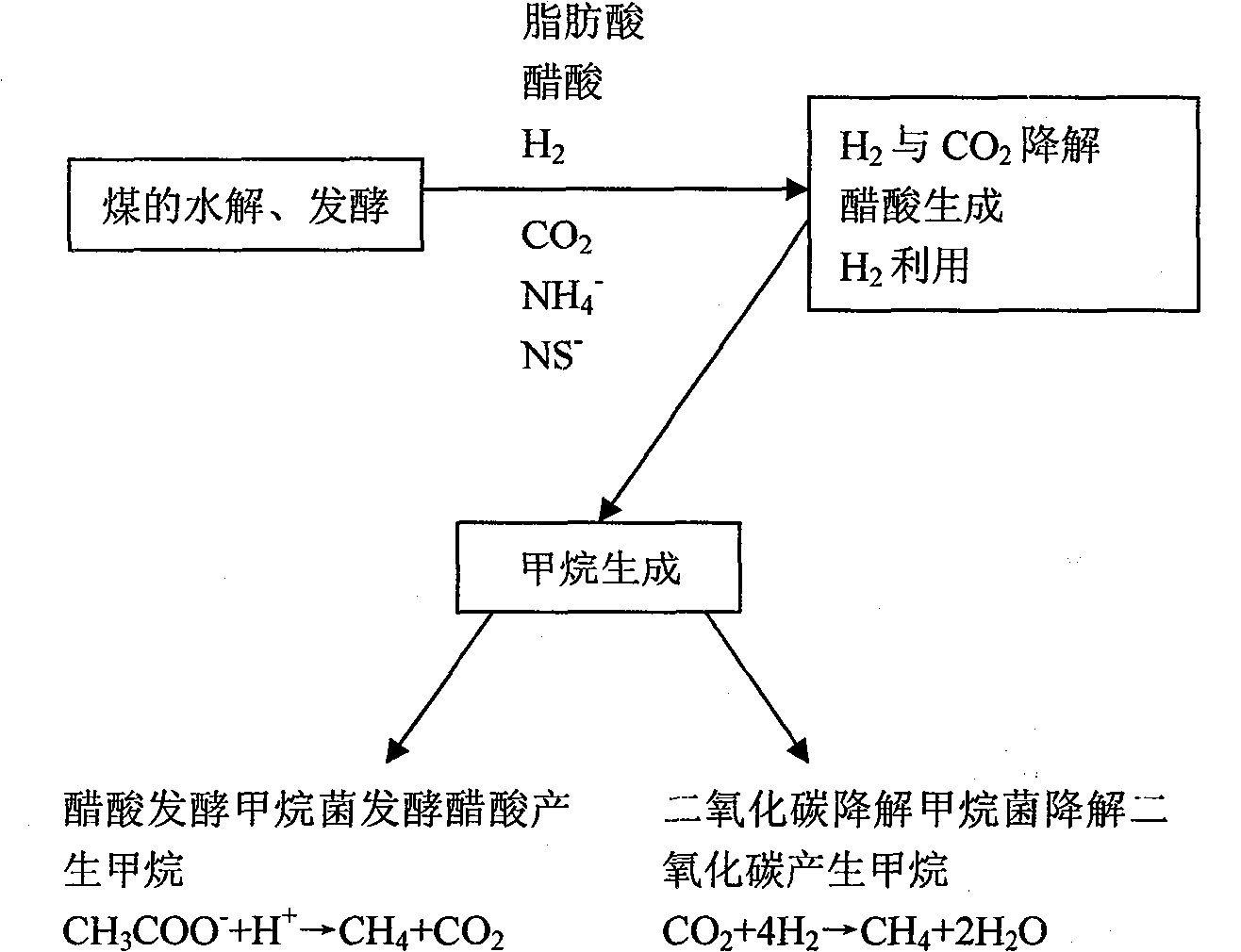

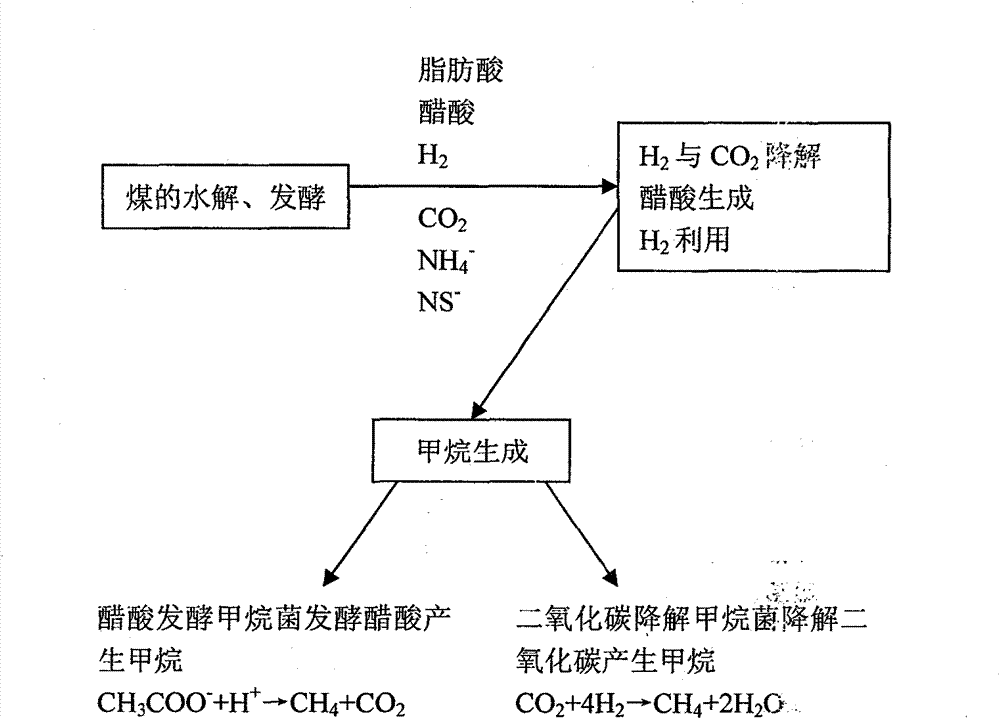

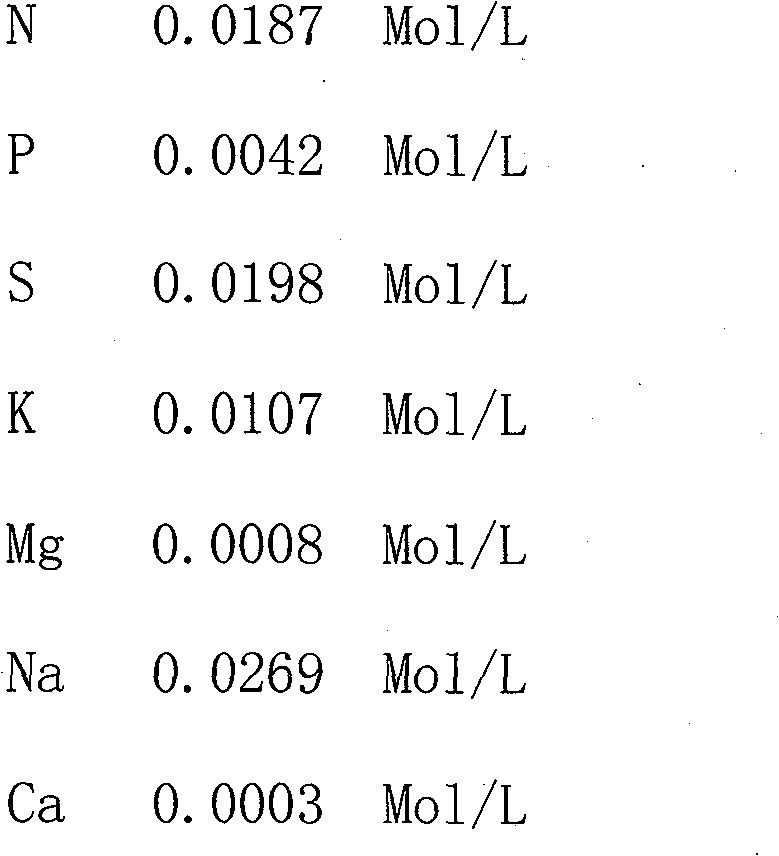

Method for making natural gas by underground coal bed microorganism

InactiveCN101922287AWill not cause pollutionImprove breathabilityConstructionsCoal gasificationProduct gasProcess engineering

The invention discloses a method for making natural gas by underground coal bed microorganism. Mainly, culture solution is utilized to cultivate and activate flora existing in the coal bed to convert underground methane flora into methane gas. The invention not only can convert coal into methane to serve as natural gas but also can improve the air permeability of the coal bed in the gas making process, so that the invention has an important meaning for improving the drainage capability of methane and ensuring upper safe extraction; more importantly, percent conversion is high, and converted coal bed resource can be reused so as to overcome the defects of the existing hot gasification method that percent conversion is low, and coal resource in the gasification area can not be reused after gasification ends.

Owner:江苏君东新材料科技发展有限公司

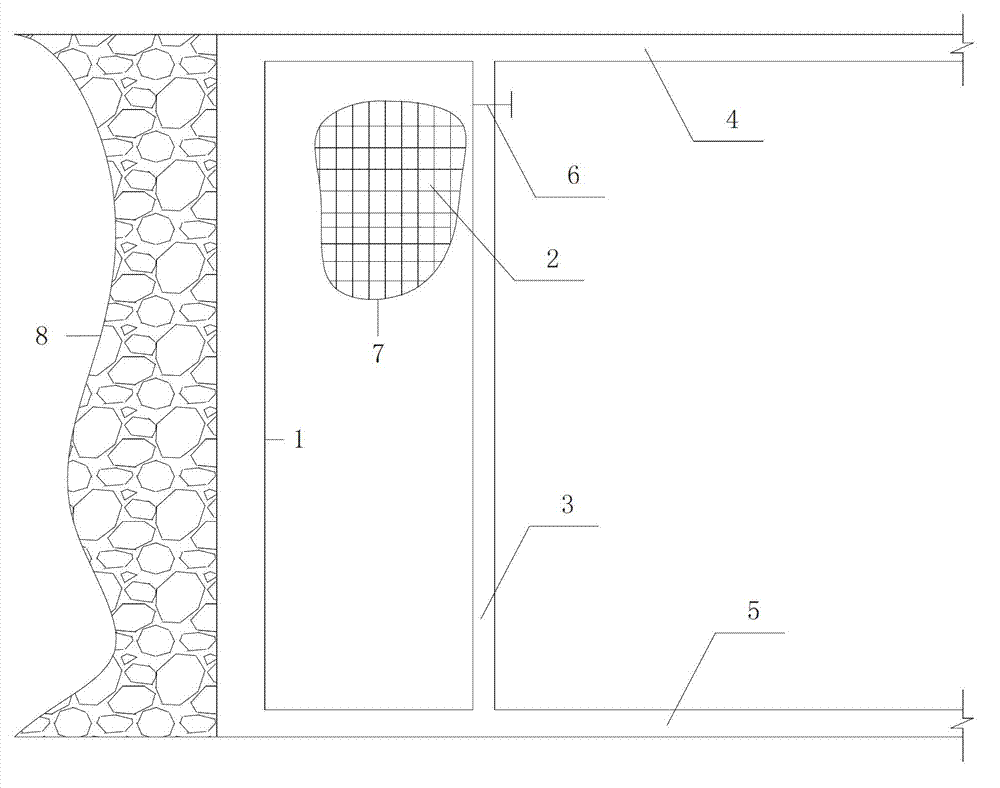

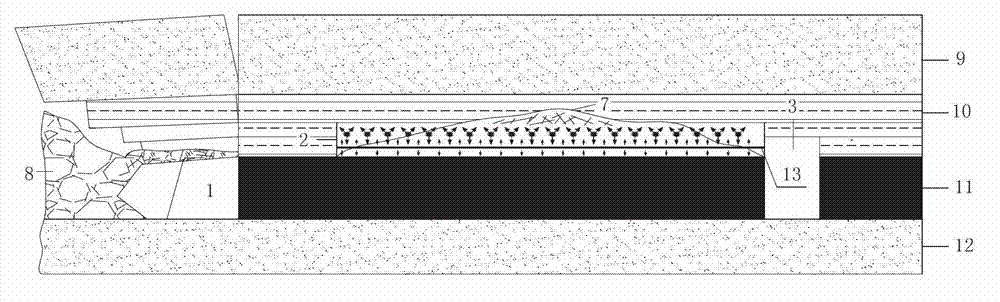

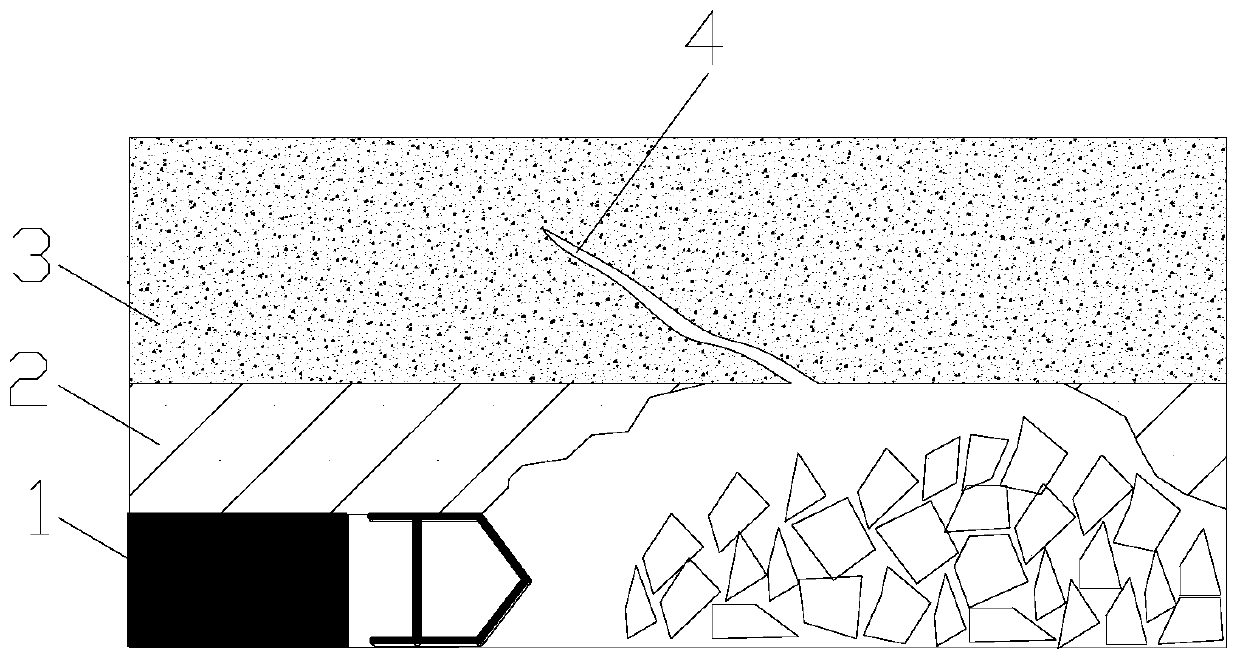

Reinforcing method for crushed top plate of coal face

InactiveCN102877858ATo achieve the purpose of strengthening the broken roofImprove reinforcementUnderground chambersTunnel liningCoalMesh grid

A reinforcing method for a crushed top plate of a coal face relates to the safety technical field of the coal face of a coal mine, can reinforce the crushed top plate through the combined action of a wire rope and slurry, forms an unique space grid reinforced structure, overcomes not only the defects of unobvious single grouting reinforcing effect and high cost, but also the defects of large labor intensity, long period and failure in fundamentally solving top leakage when the crushed top plate is treated by erecting a shed, and is obvious in crushed top plate reinforcing effect. Integrated with the advantages of grouting reinforcement, and matched with a specially excavated measure laneway, the method is free of time and space, and can pre-reinforce a composite thin crushed top plate before coal bed exploitation, and reinforce an area with the possibility of top leakage during coal bed exploitation, so as to ensure safe stopping of the coal face.

Owner:ANHUI UNIV OF SCI & TECH

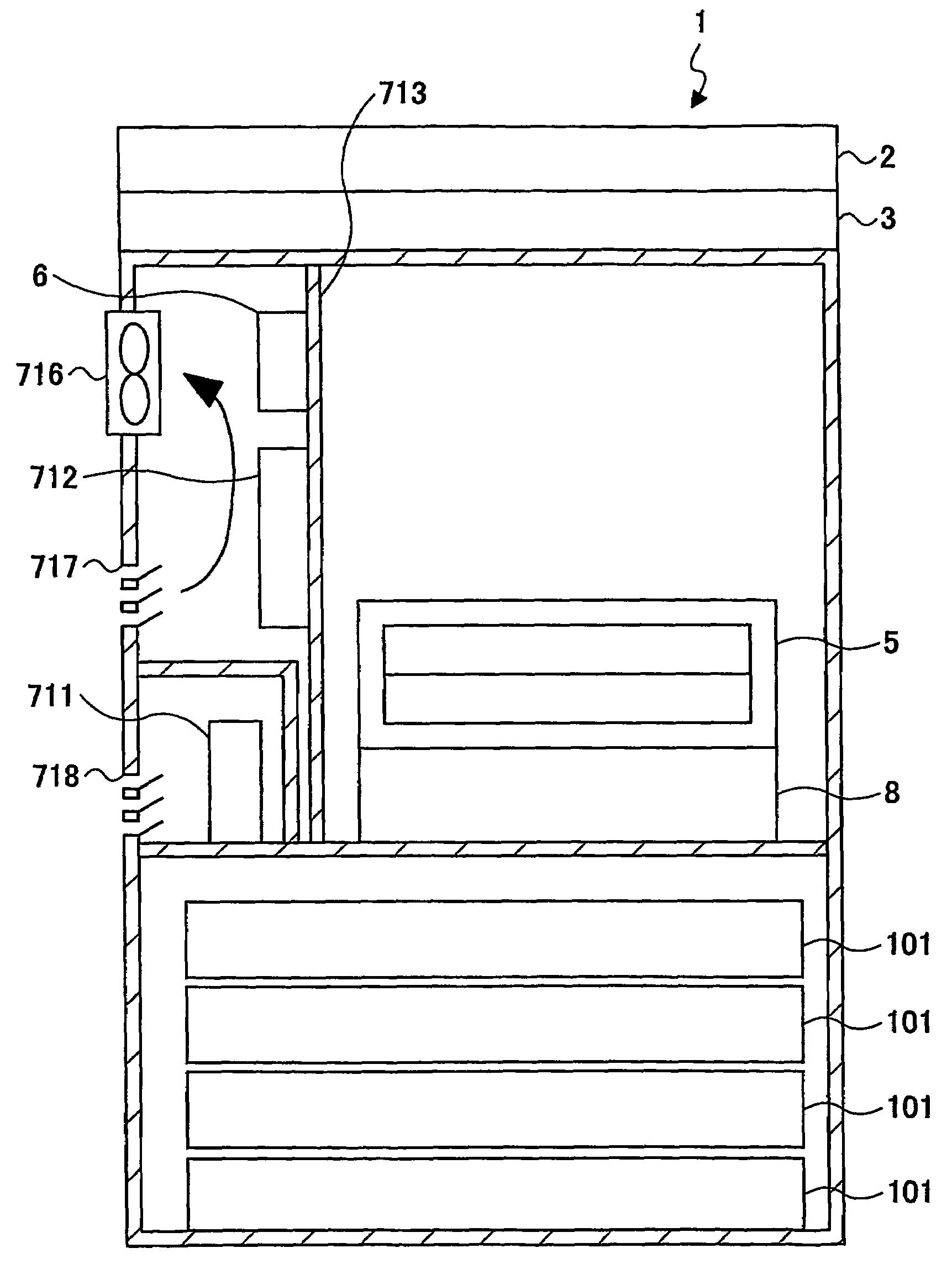

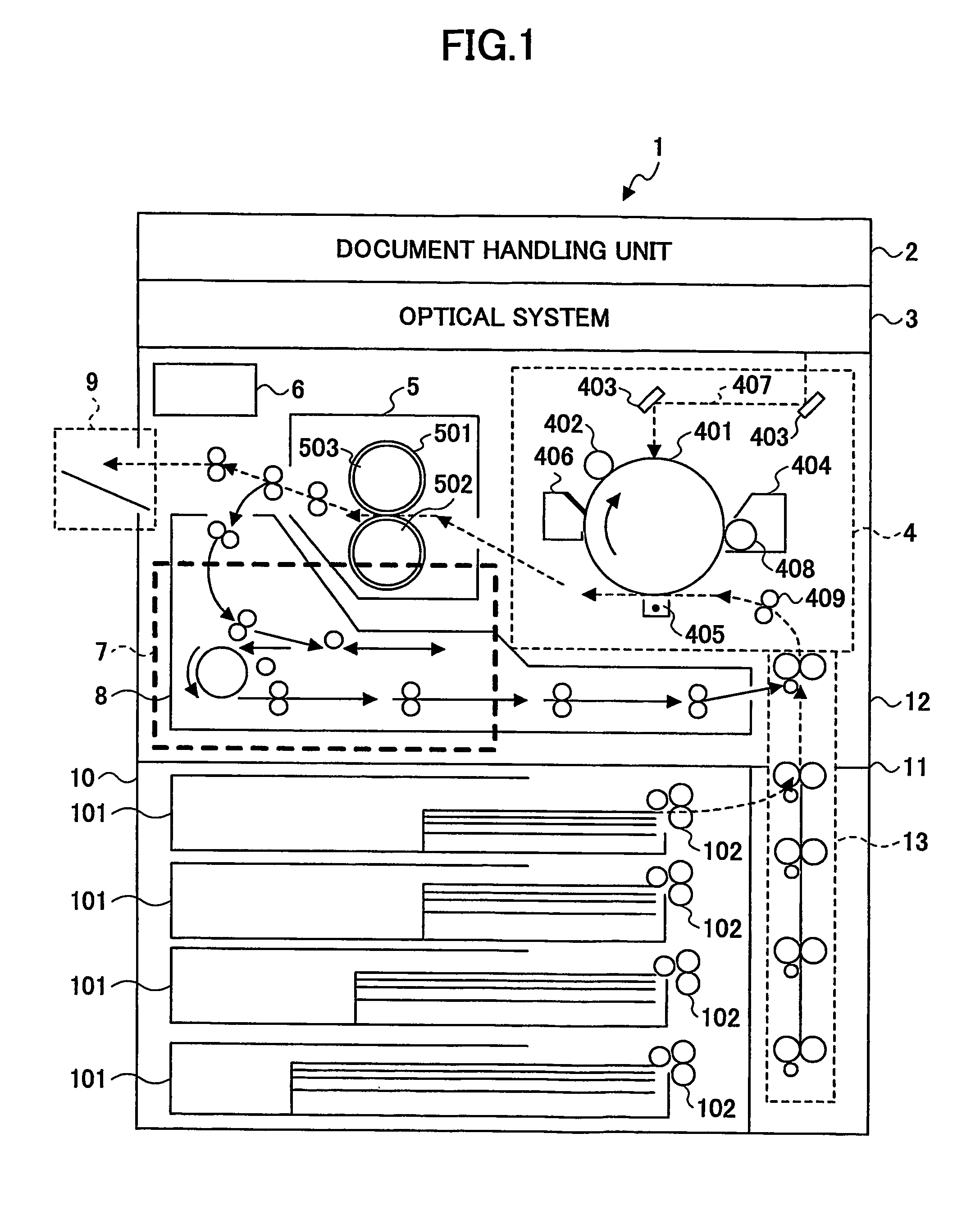

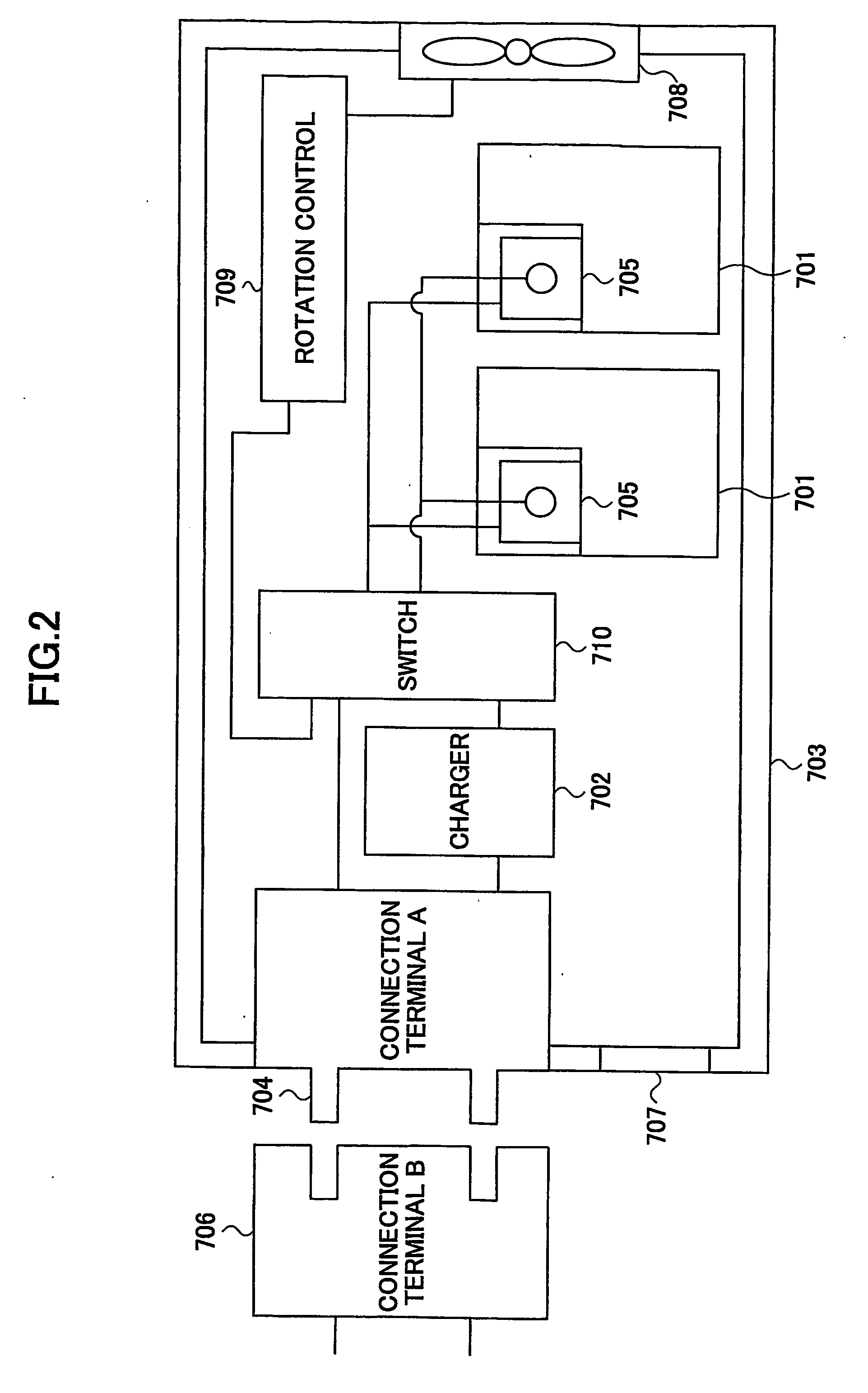

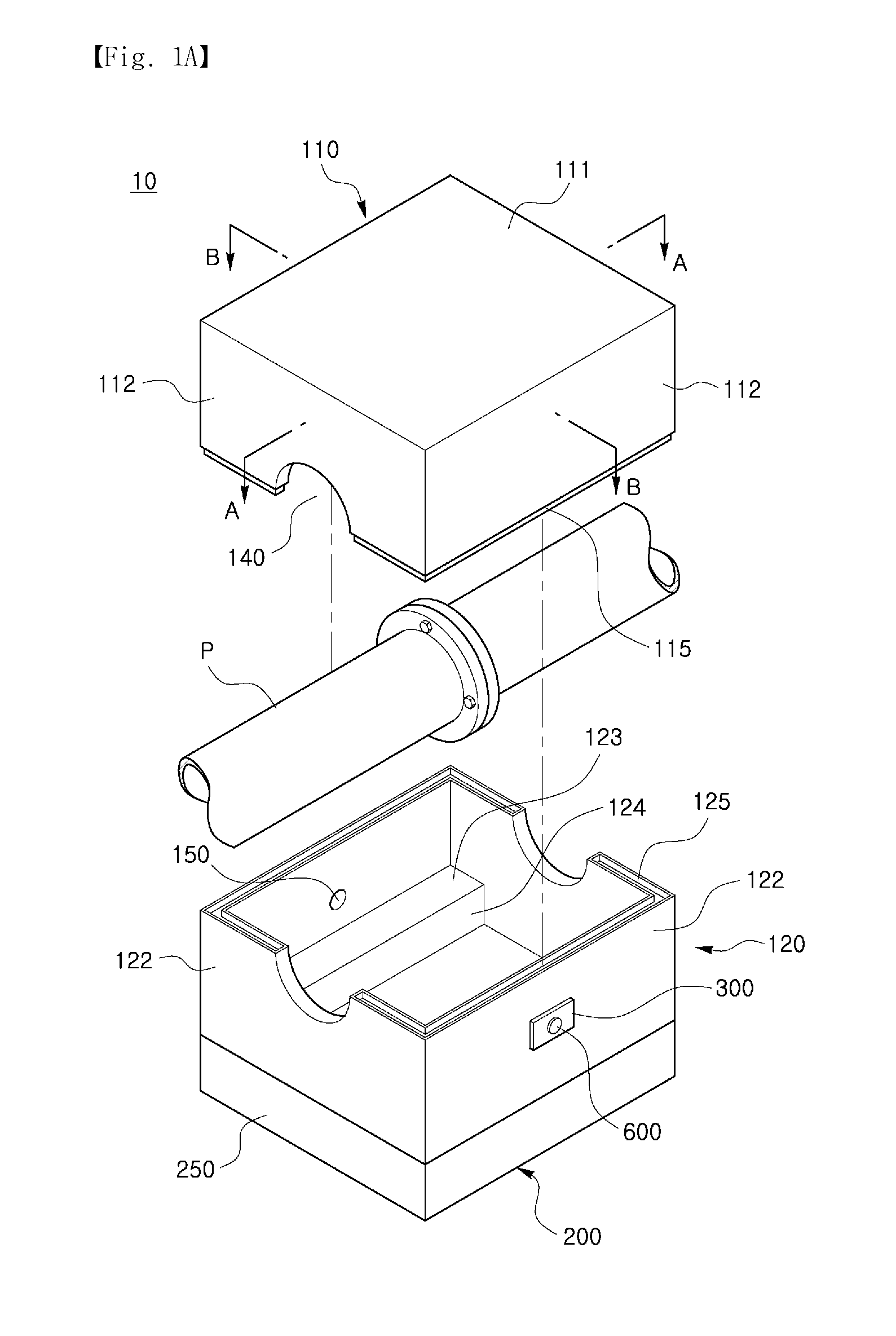

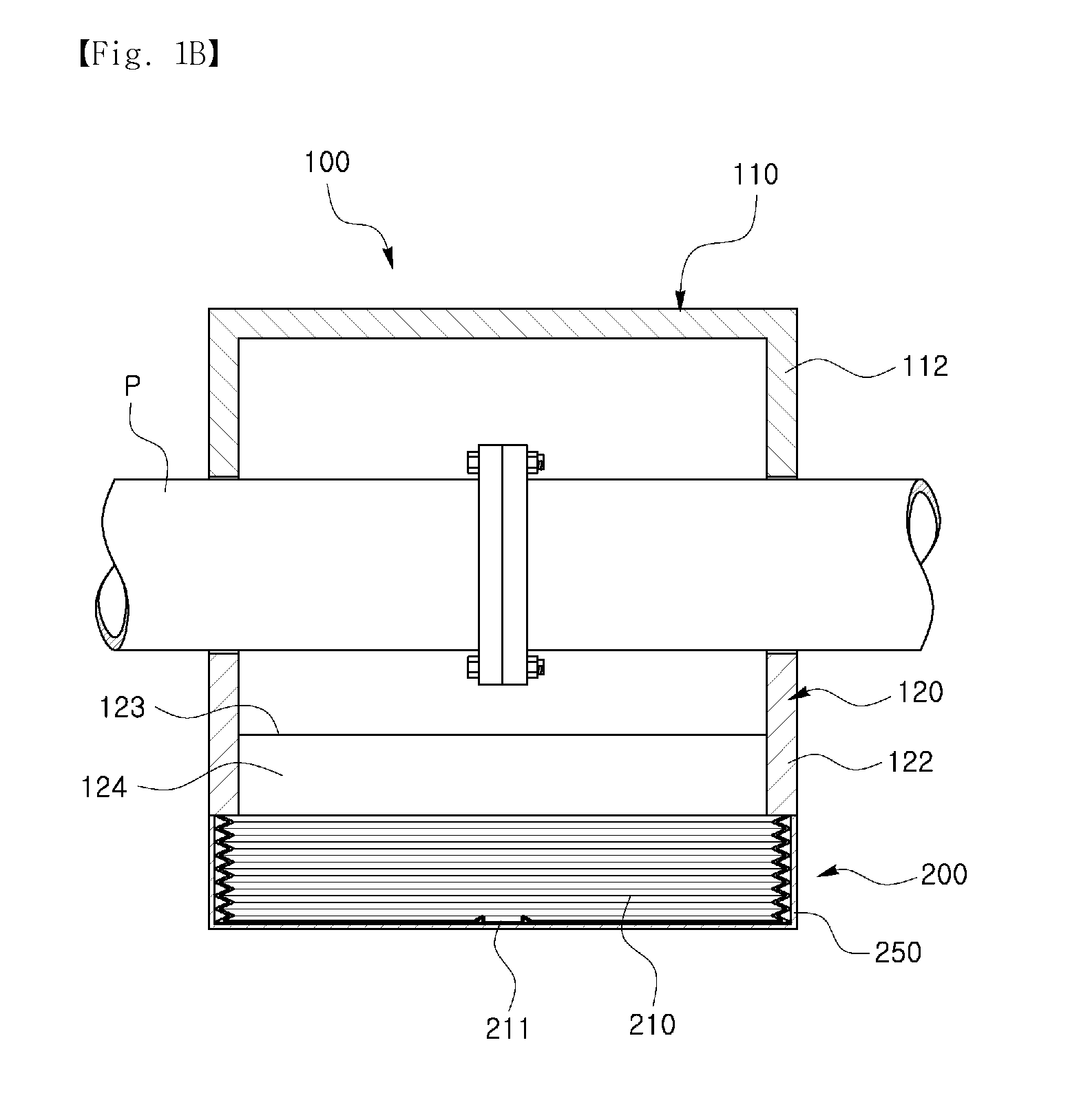

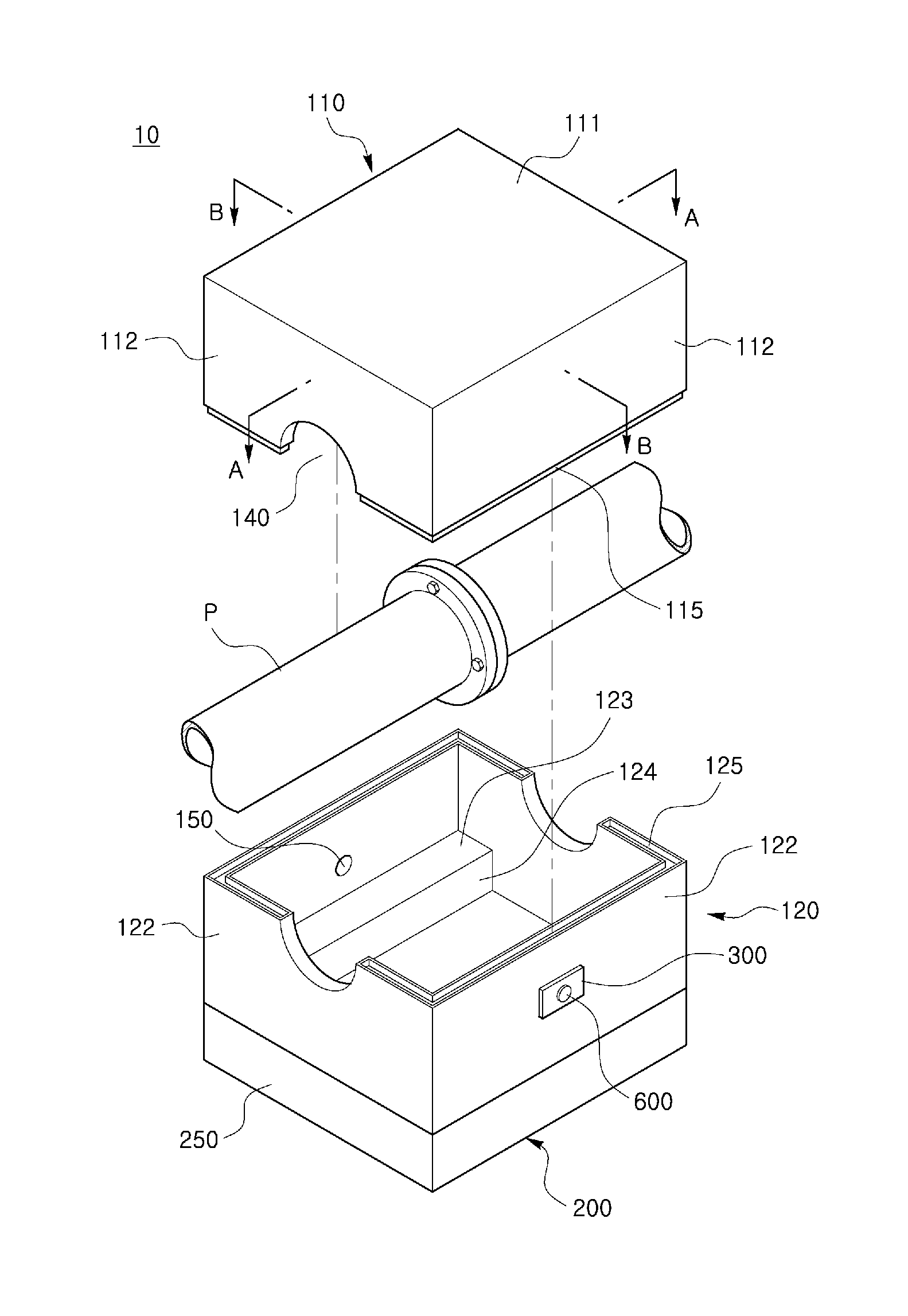

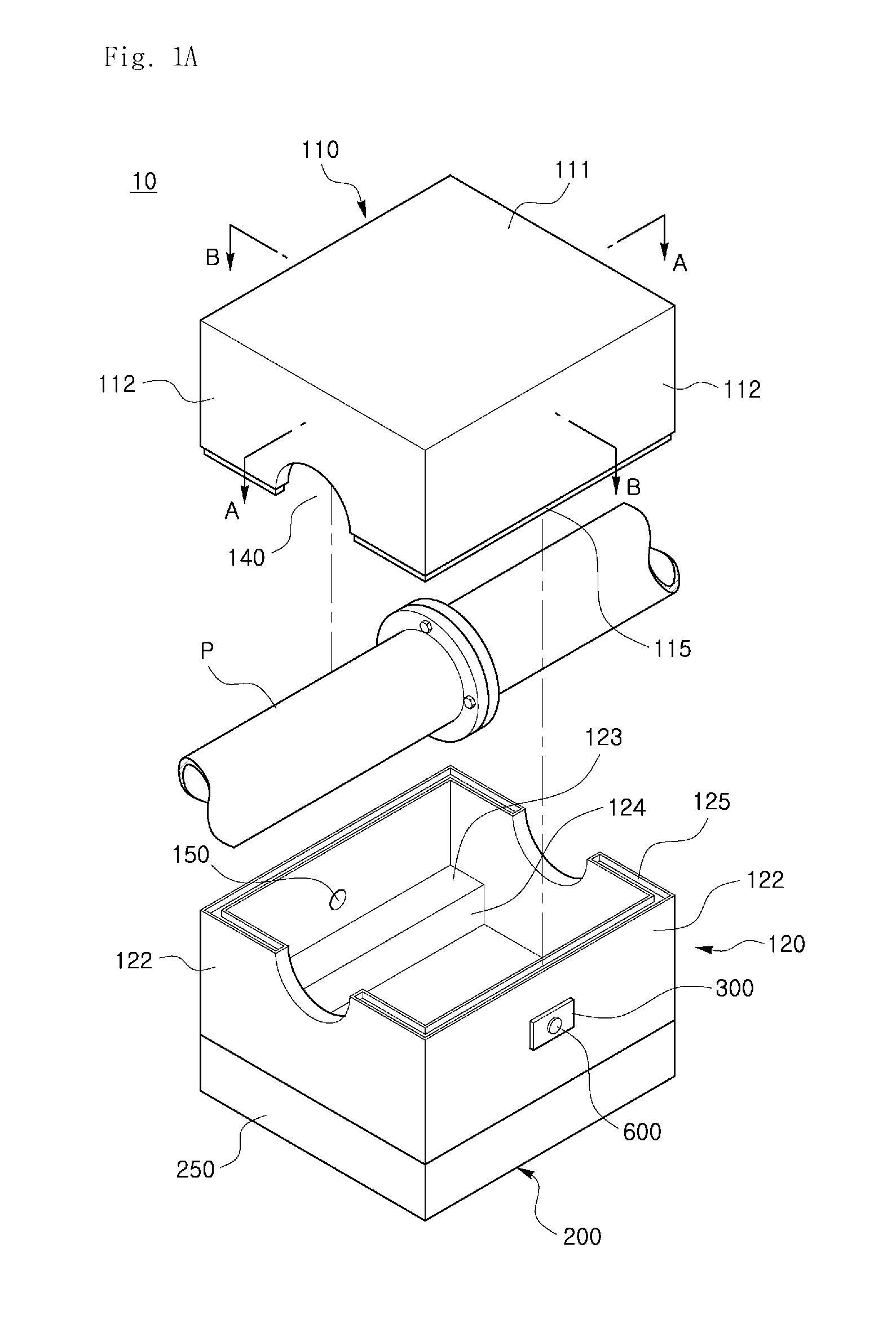

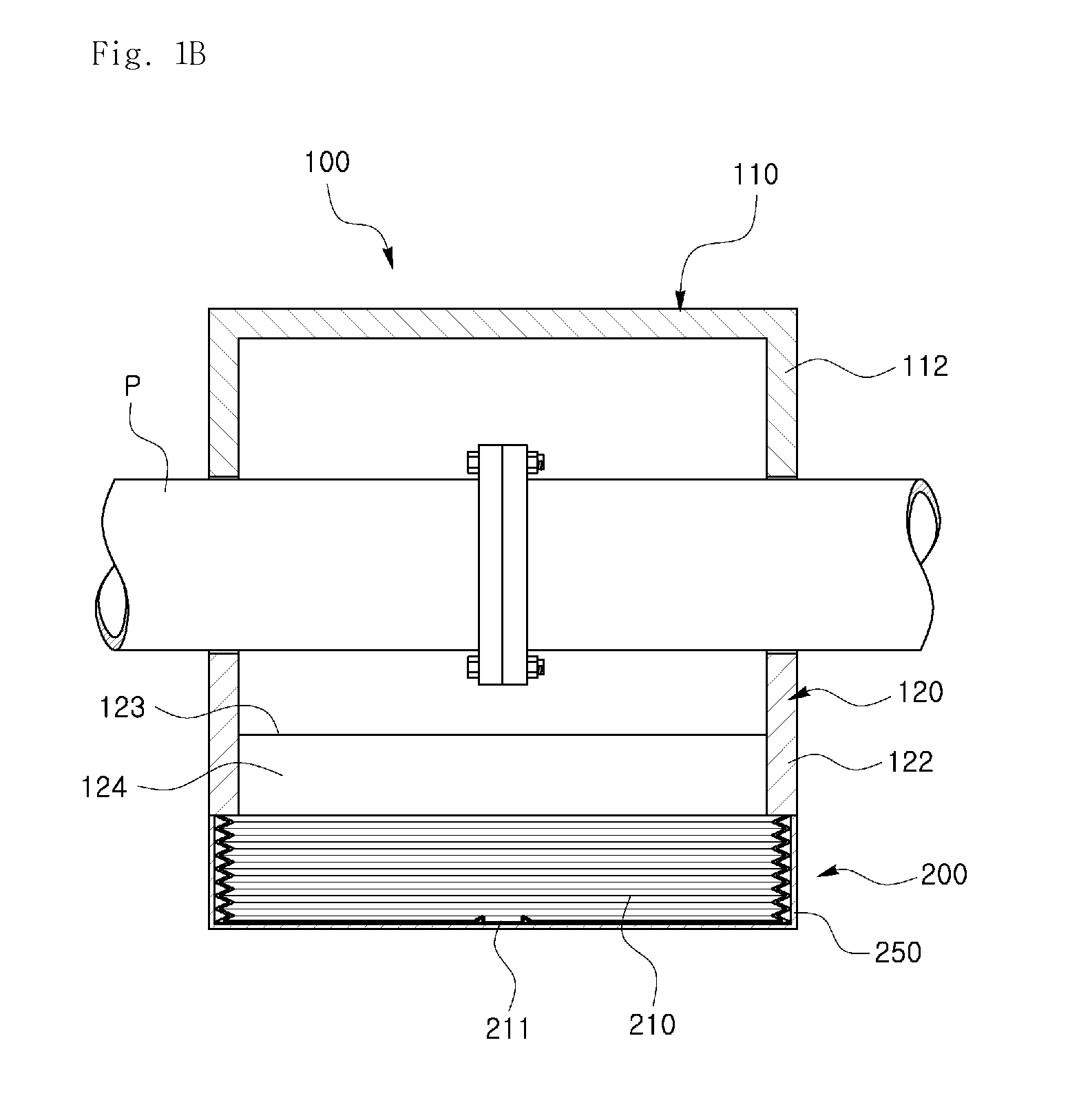

Image forming apparatus with another secondary power supply

ActiveUS7313341B2Avoid condensationReduce decreaseElectrographic process apparatusImage formationEngineering

Owner:RICOH KK

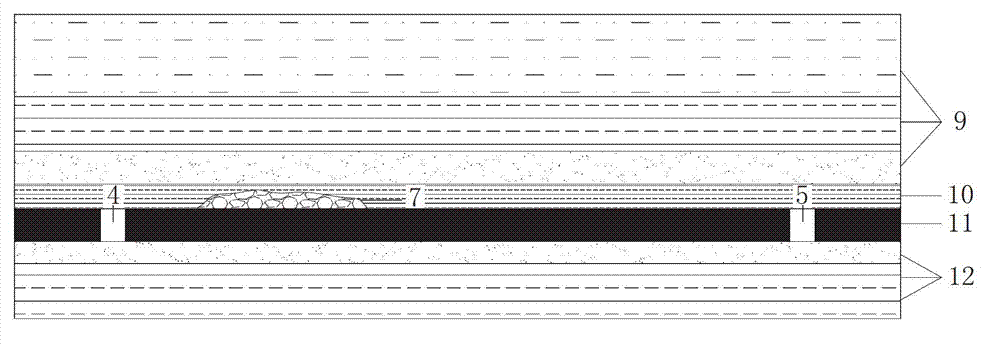

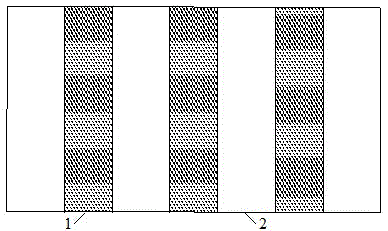

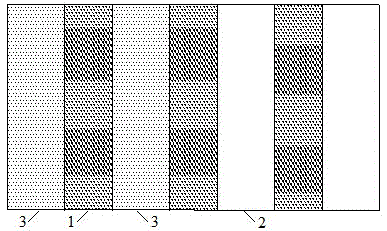

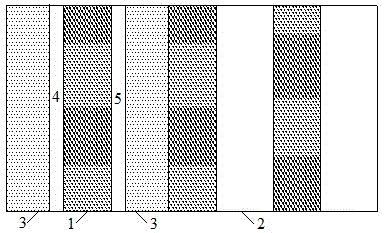

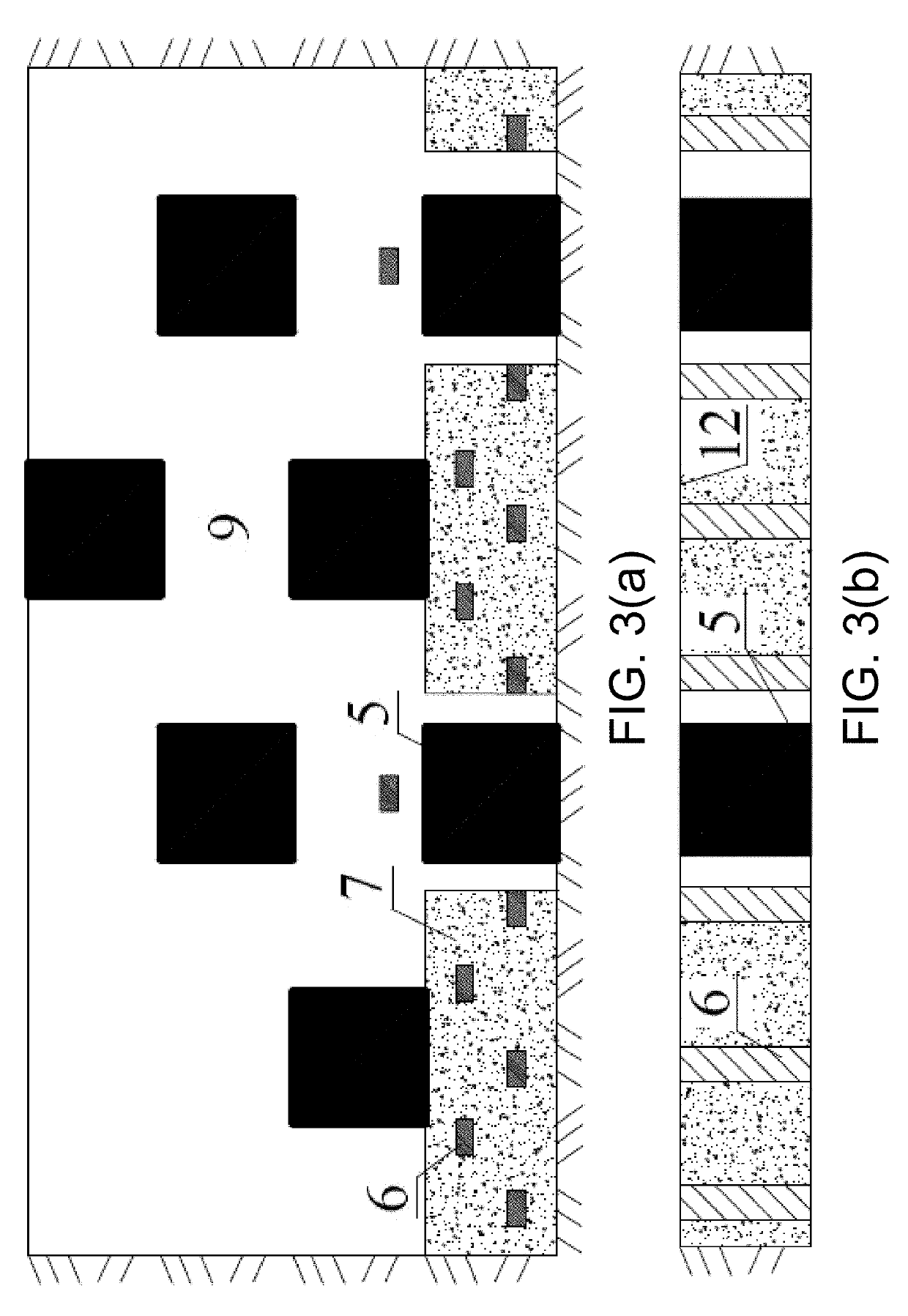

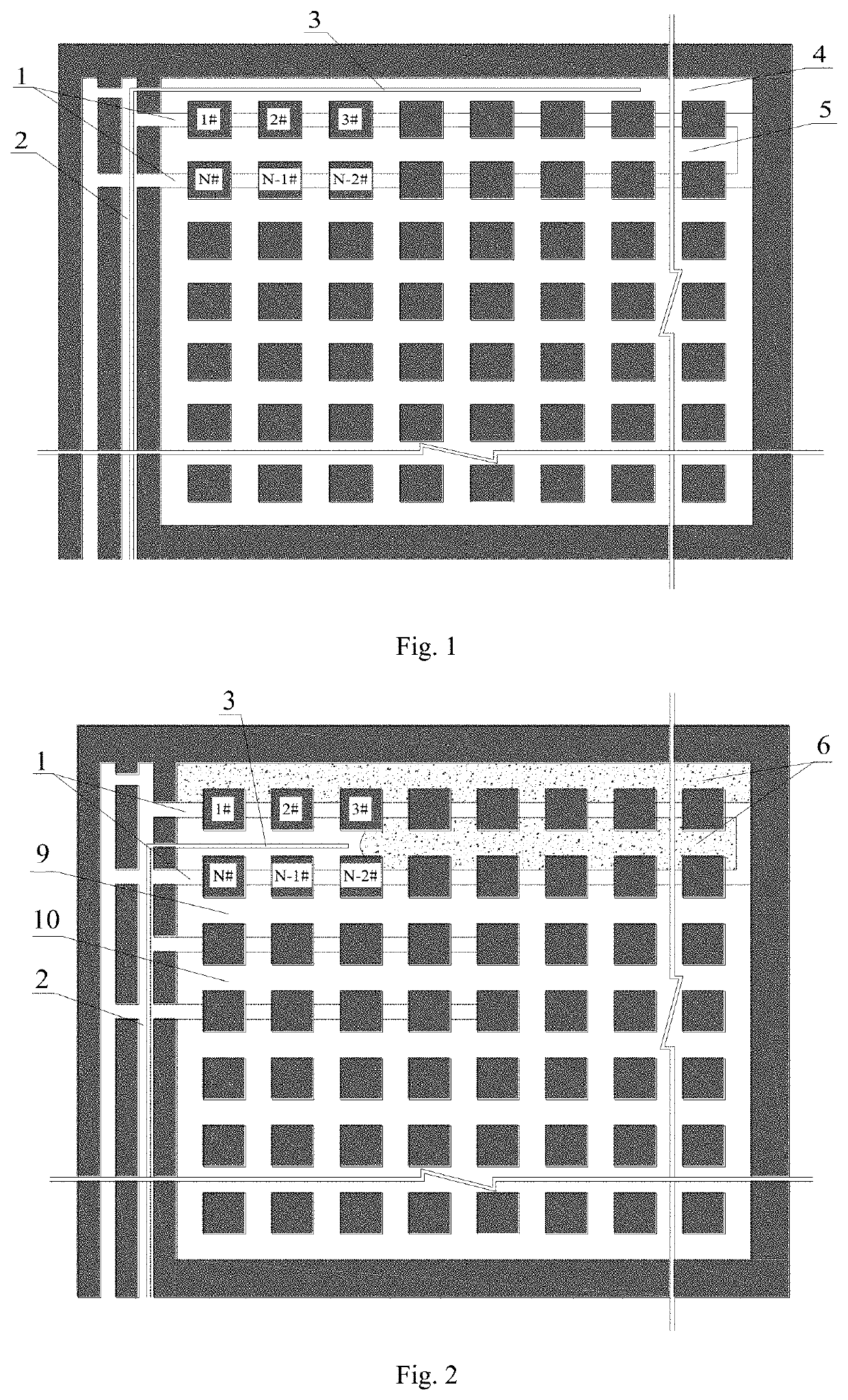

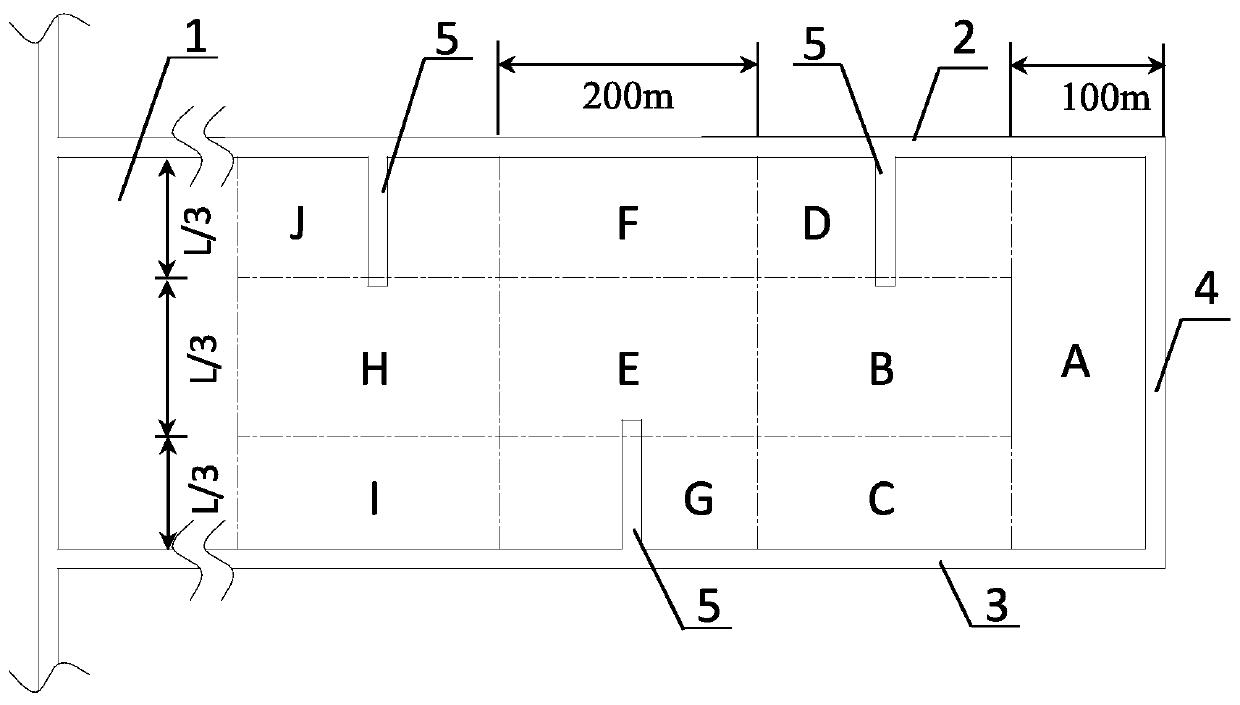

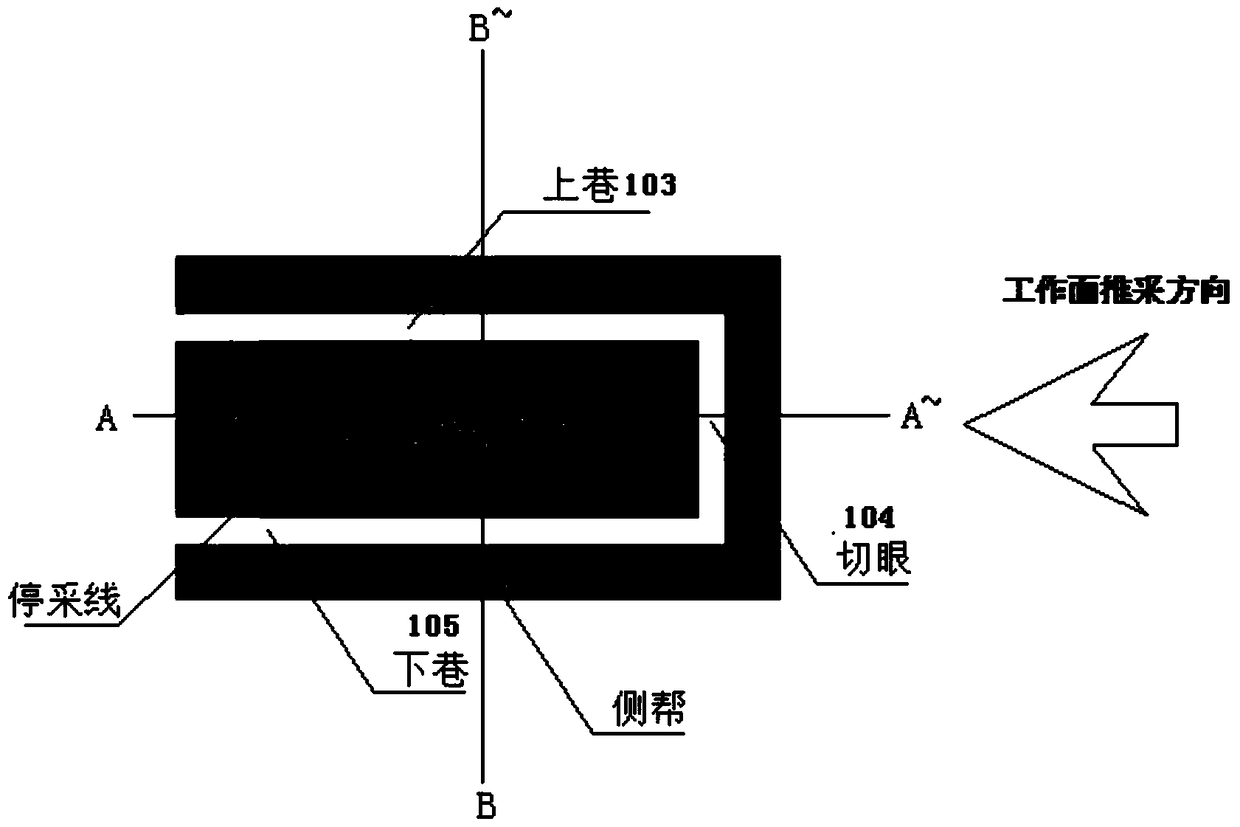

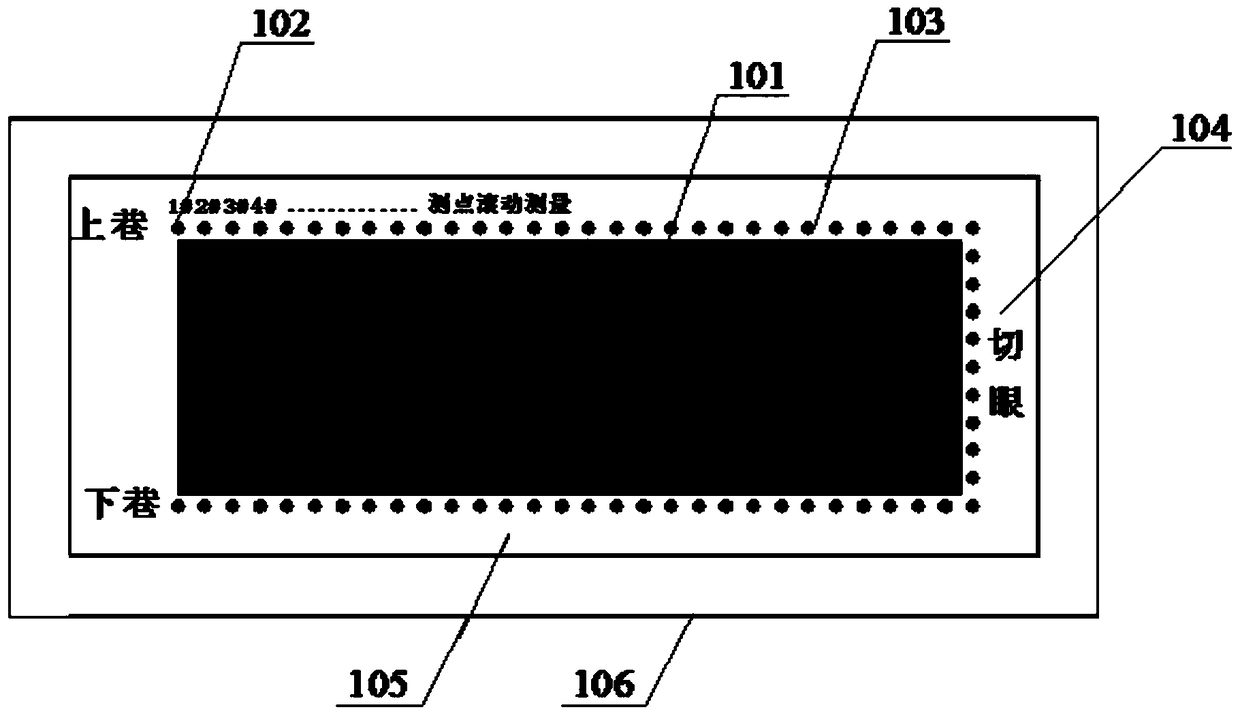

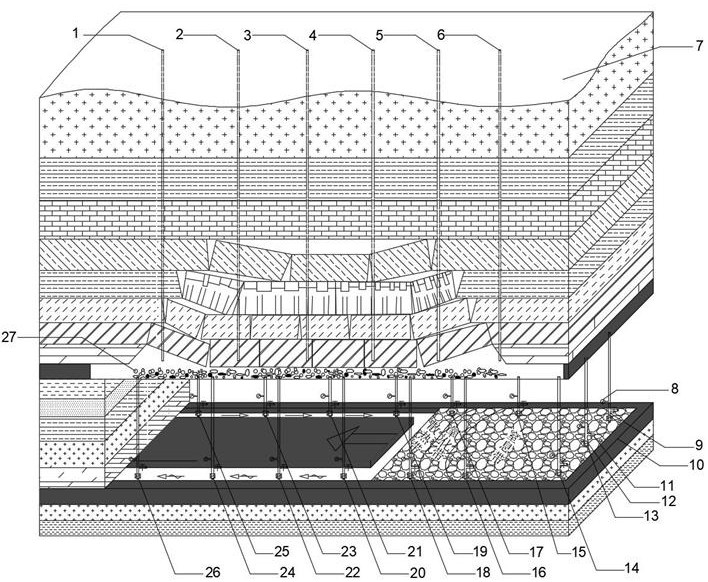

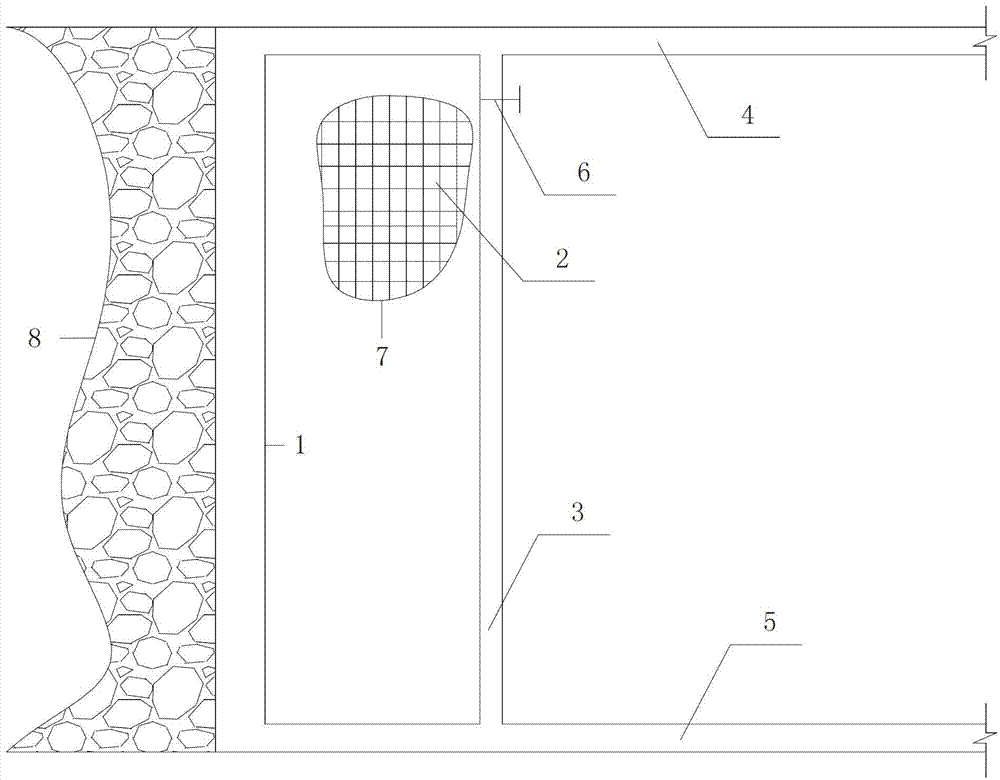

Method for completely filling two sides of pillars with repeated mining and residual mining area remaining coal pillars

ActiveCN105422099AGuaranteed safe recoveryReduce resource requirementsUnderground miningSurface miningMining engineeringCoal pillar

The invention discloses a method for completely filling two sides of pillars with repeated mining and residual mining area remaining coal pillars. The method comprises the steps that on the basis of exploring and finding out remaining coal mining area remaining coal pillar and pillar mining area distribution positions, sizes and the like, remaining coal mining area remaining coal pillars are laterally protected sequentially by adopting the method for complete filling of the two sides of the segmentation pillars, conveyor gateways and air return gateways are tunneled in filling bodies on the two sides of the pillars, and short-wall mechanical working face repeated mining and residual mining area remaining coal pillars are arranged. According to the method, the residual mining area remaining coal pillars are sufficiently utilized, the contradiction between the coal resource finiteness and consumer demand infiniteness is relieved, instant instability or domino instability and other dynamic disaster happening on the pillar-type system mining remaining coal pillars under the effect of long-term creep deformation are avoided, and meanwhile safe repeated mining of the residual mining area remaining coal pillars is ensured by means of the filling bodies on the two sides of the pillars.

Owner:TAIYUAN UNIV OF TECH

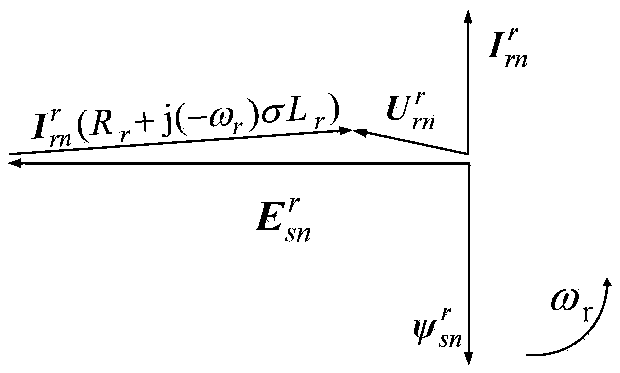

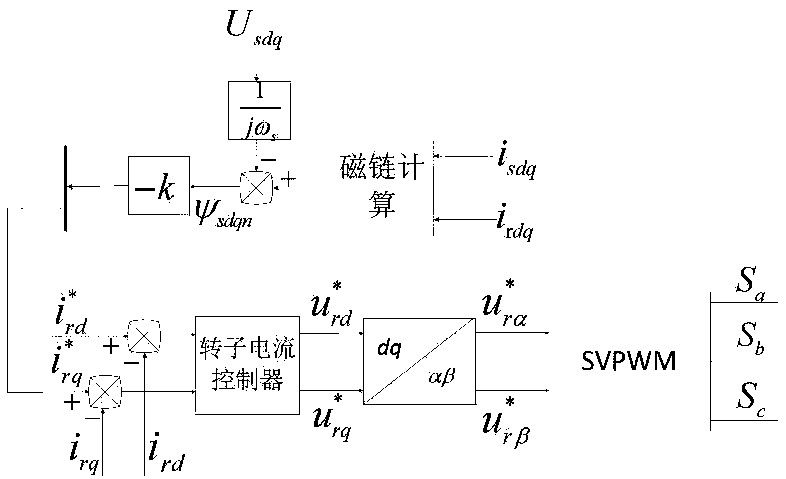

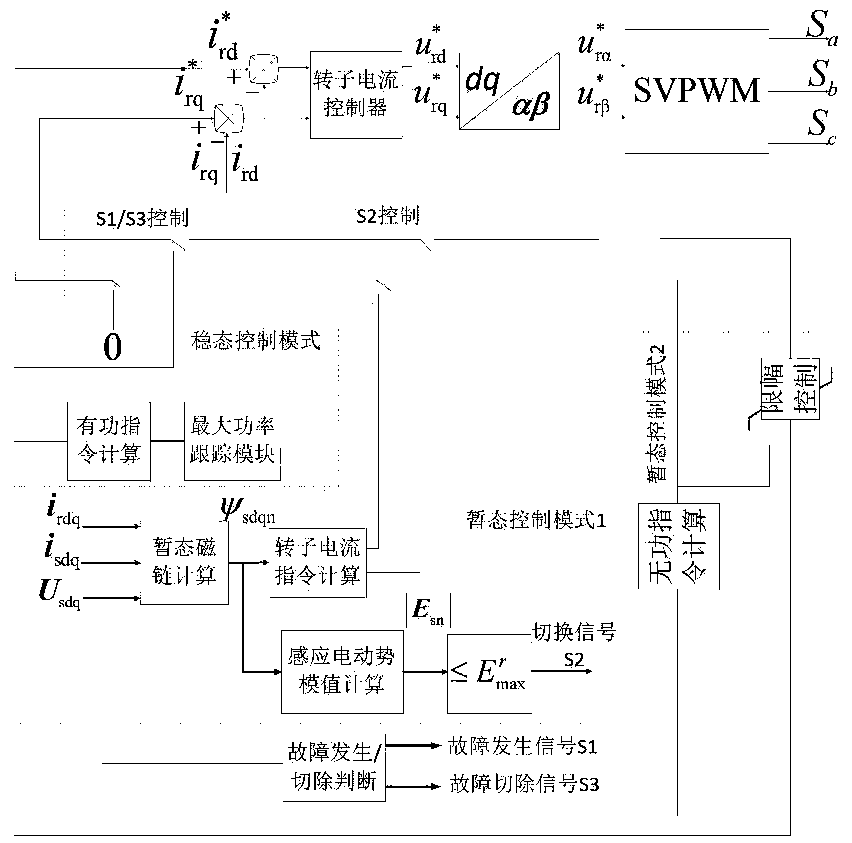

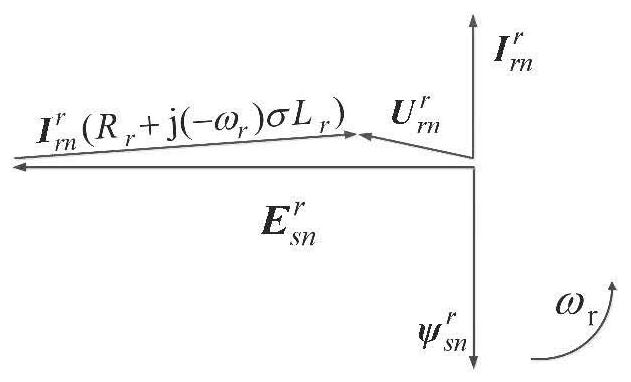

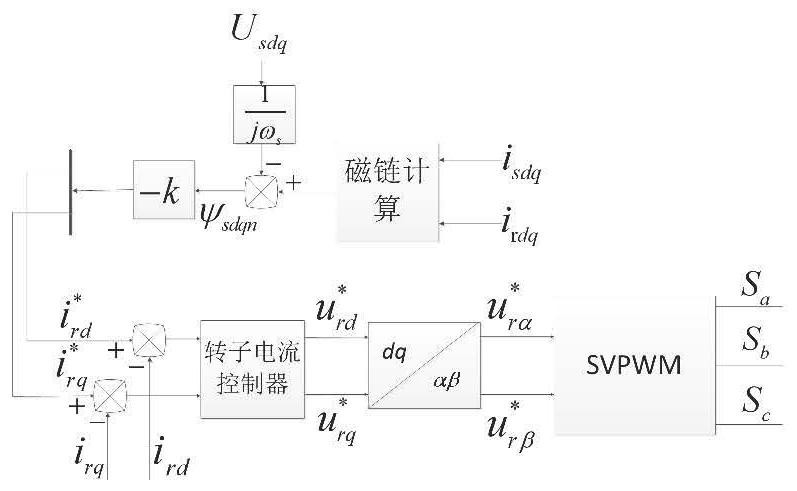

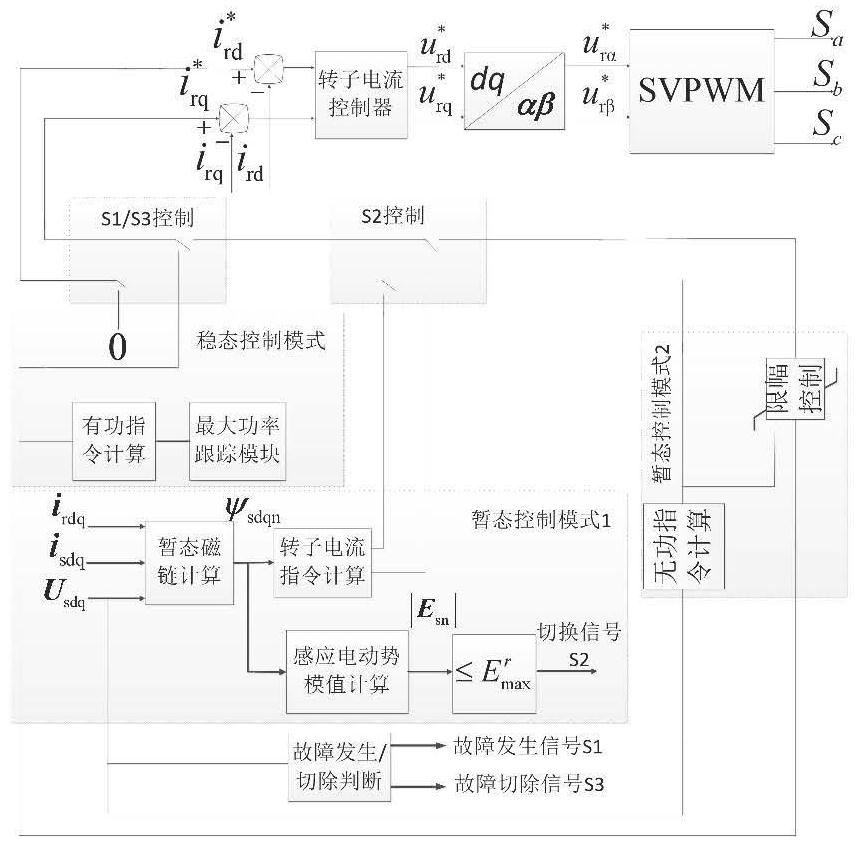

Comprehensive low voltage ride-through method for doubly-fed fan based on stator series dynamic reactor

ActiveCN108879779AImprove reactive supportThe purpose of improving reactive power supportSingle network parallel feeding arrangementsWind energy generationPeak valueEngineering

The invention relates to a comprehensive low voltage ride-through method for a doubly-fed fan based on a stator series dynamic reactor. The method comprises the following steps: when the grid voltagedrop is detected, performing control according to a transient control mode 1, wherein the transient control mode 1 is a comprehensive traversing mode in which the stator series reactor with a large value is input and a RSC adopts a control strategy of active transient flux linkage attenuation, and the setting principle of the large reactor in the mode 1 is to ensure that the peak value of the rotor current does not exceed the limit after the fault occurs; observing the modulus value of the transient induced electromotive force in real time, and switching to a control mode 2 when the modulus value decays to the set threshold value, wherein the setting principle is to ensure that the rotor current does not exceed the limit after reactor witching; restoring the normal control of the fan, andcutting off the series reactor after a delay of 100 ms, when the grid voltage returns to normal.

Owner:TIANJIN UNIV

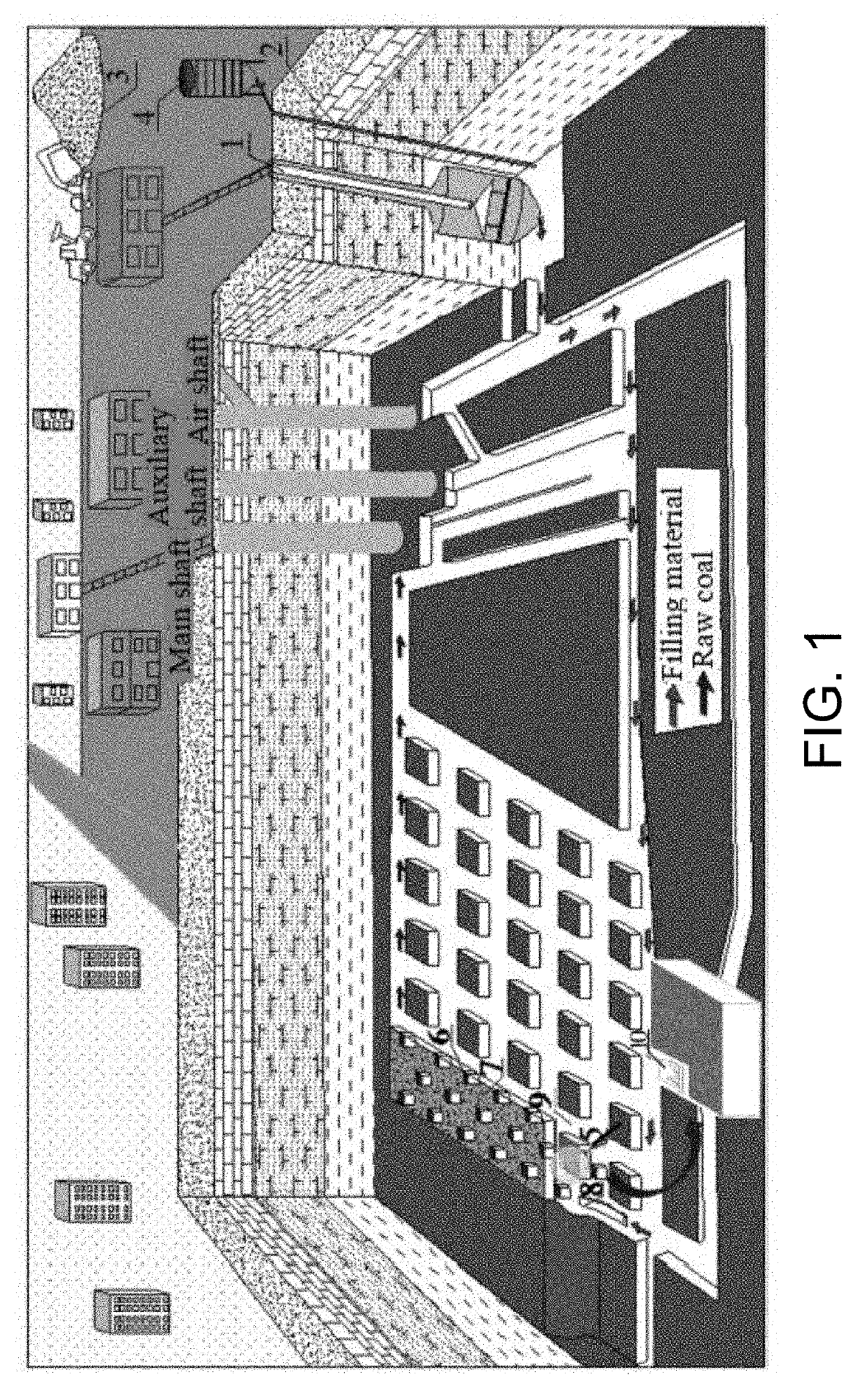

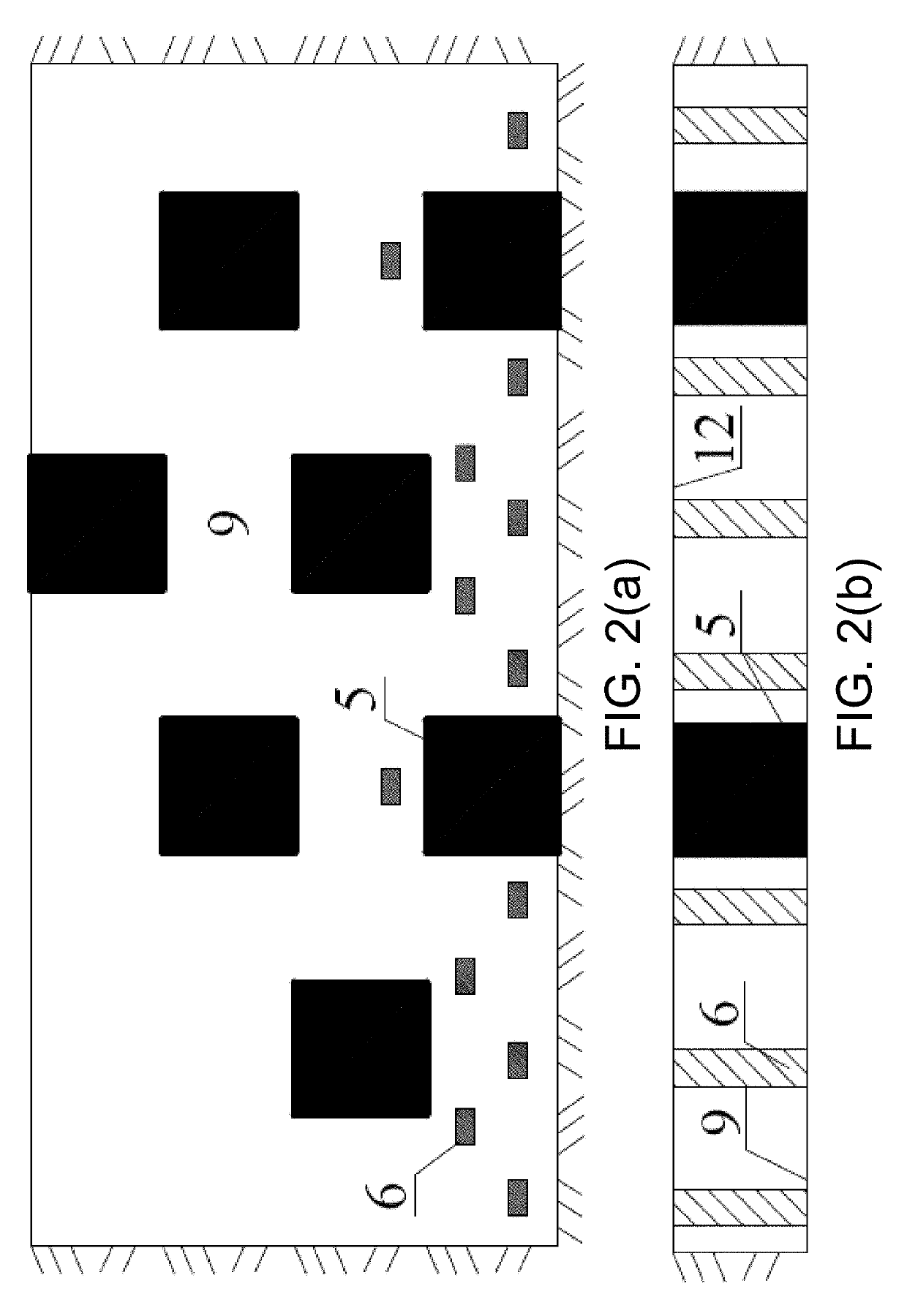

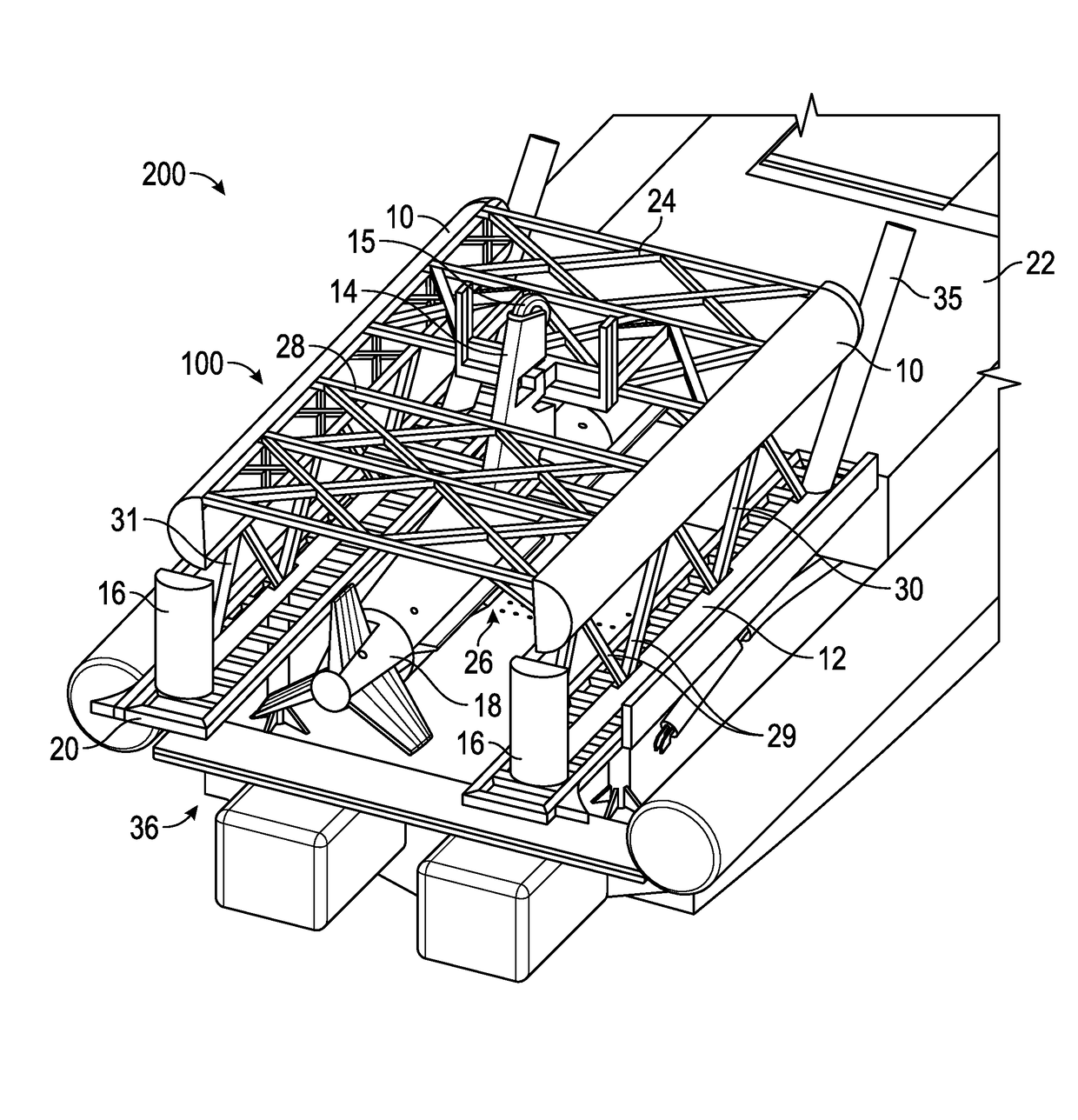

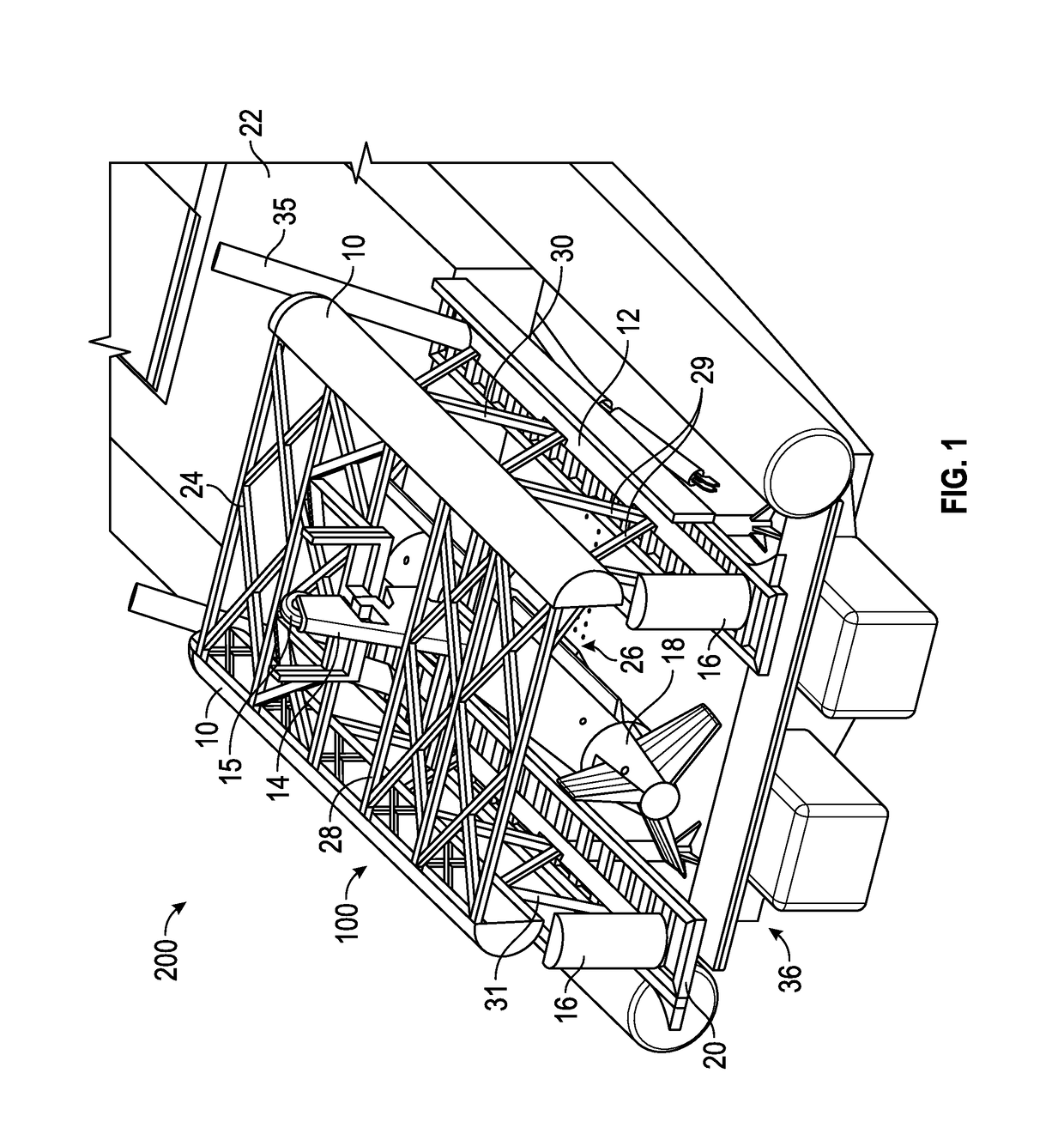

Method for recovering room-mining coal pillars by solid filling in synergy with artificial pillars

ActiveUS20190301283A1Ensure safe and efficient recoveryReduce investmentUnderground miningSurface miningRoom and pillar miningSupporting system

A method for recovering room-mining coal pillars by solid filling in synergy with artificial pillars. Solid materials and cementing materials on the ground are conveyed through a feeding well and a pipeline to a room-and-pillar goaf, a plurality of artificial pillars is cast at an interval in a coal room area, and gangue is cast to fill other regions of the coal room using a gangue casting machine. Under joint support by the artificial pillars and the coal room filler, coal pillars are recovered using a continuous coal mining machine, artificial pillars are cast in the original coal pillar area after recovery, and gangue is cast to fill the original coal pillar area using the gangue casting machine. A system for recovering room-mining coal pillars by solid filling in synergy with artificial pillars mainly includes a material conveying system, a joint support system, and a coal pillar recovery system. By constructing pillar grooves, casting artificial pillars, casting gangue to fill a goaf, and recovering coal pillars, the recovery rate of coal resources can be increased, and room-mining coal pillar recovery theories and technologies in China can be enriched while harmonious development of environmental protection and resource exploitation is promoted.

Owner:CHINA UNIV OF MINING & TECH

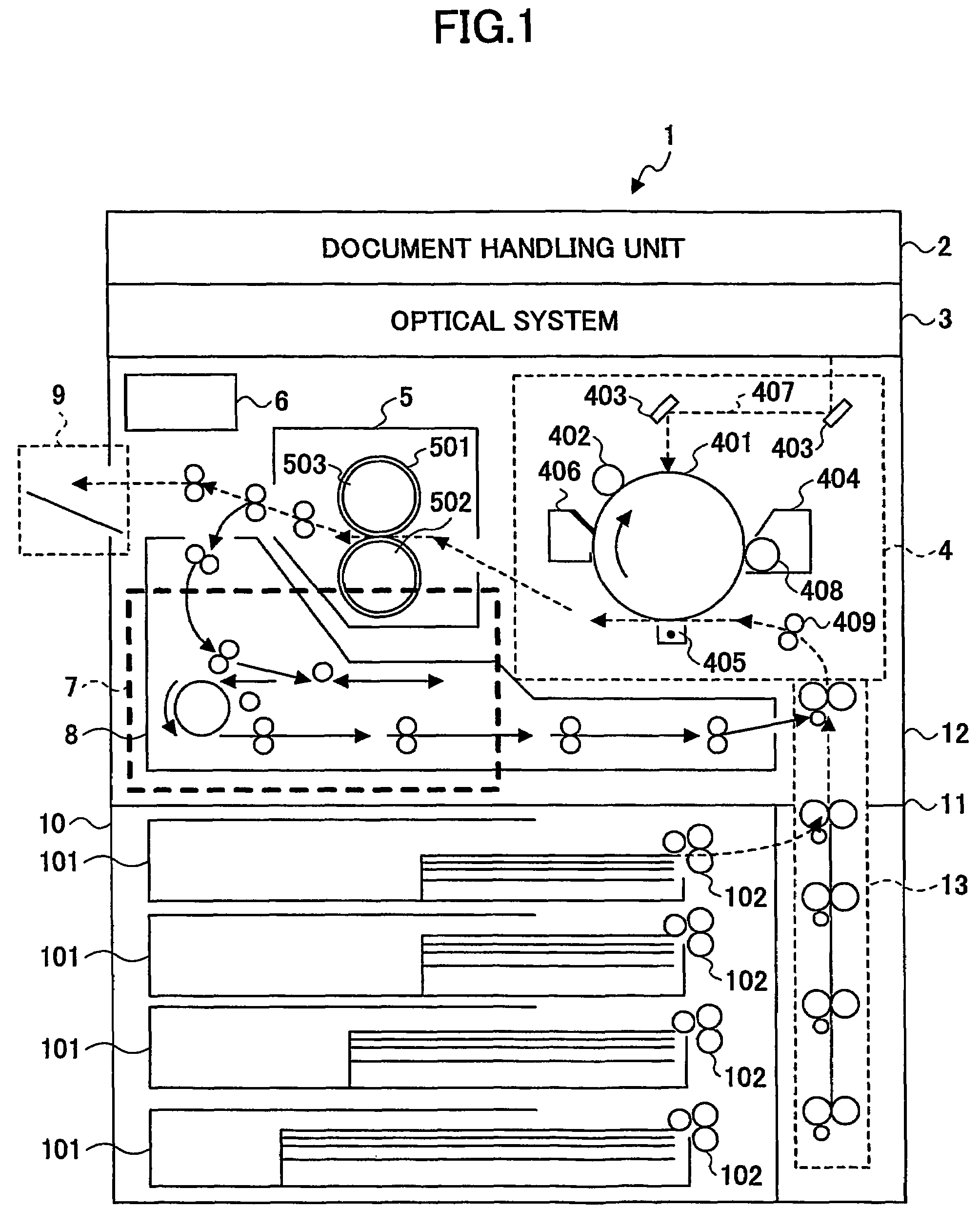

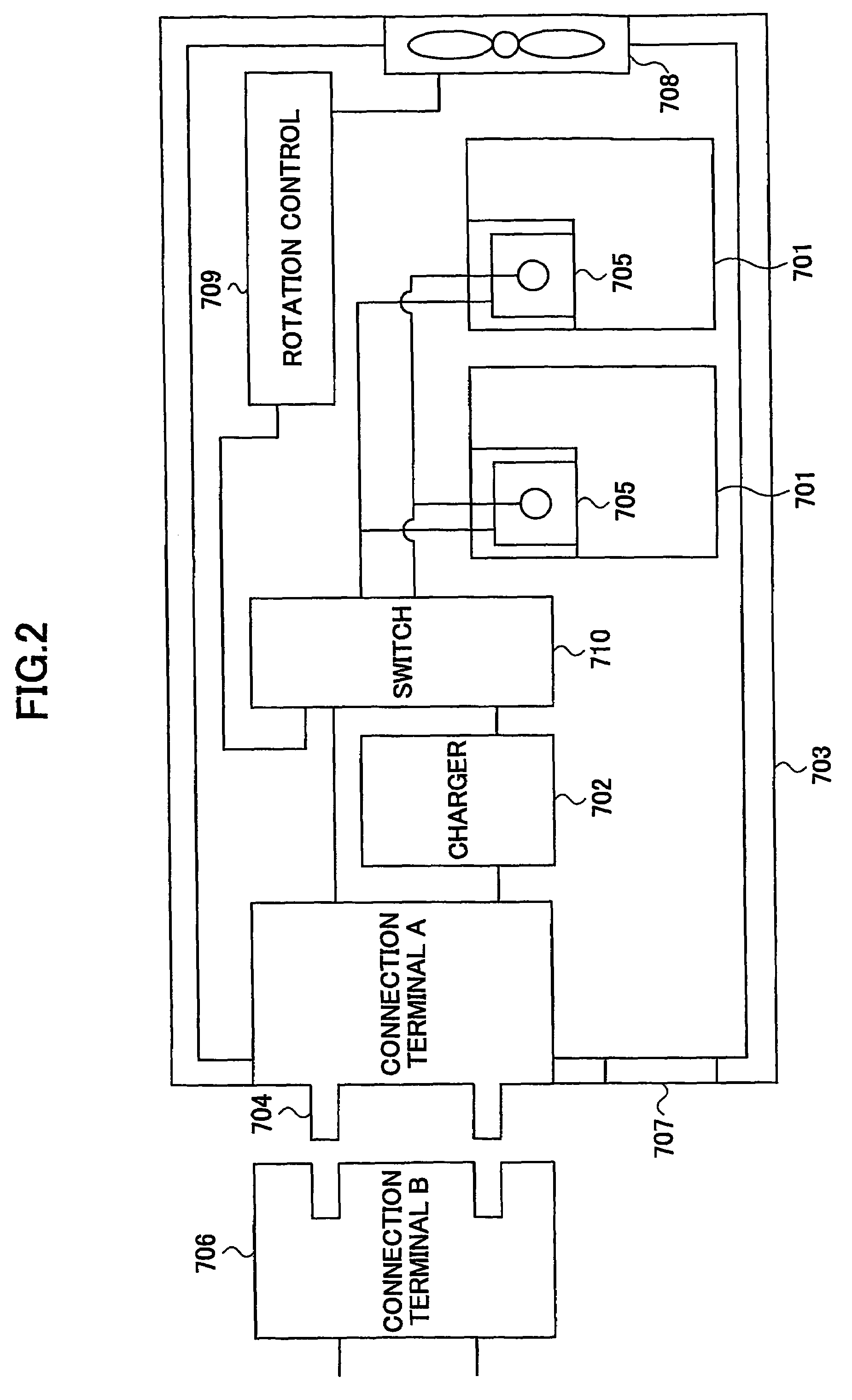

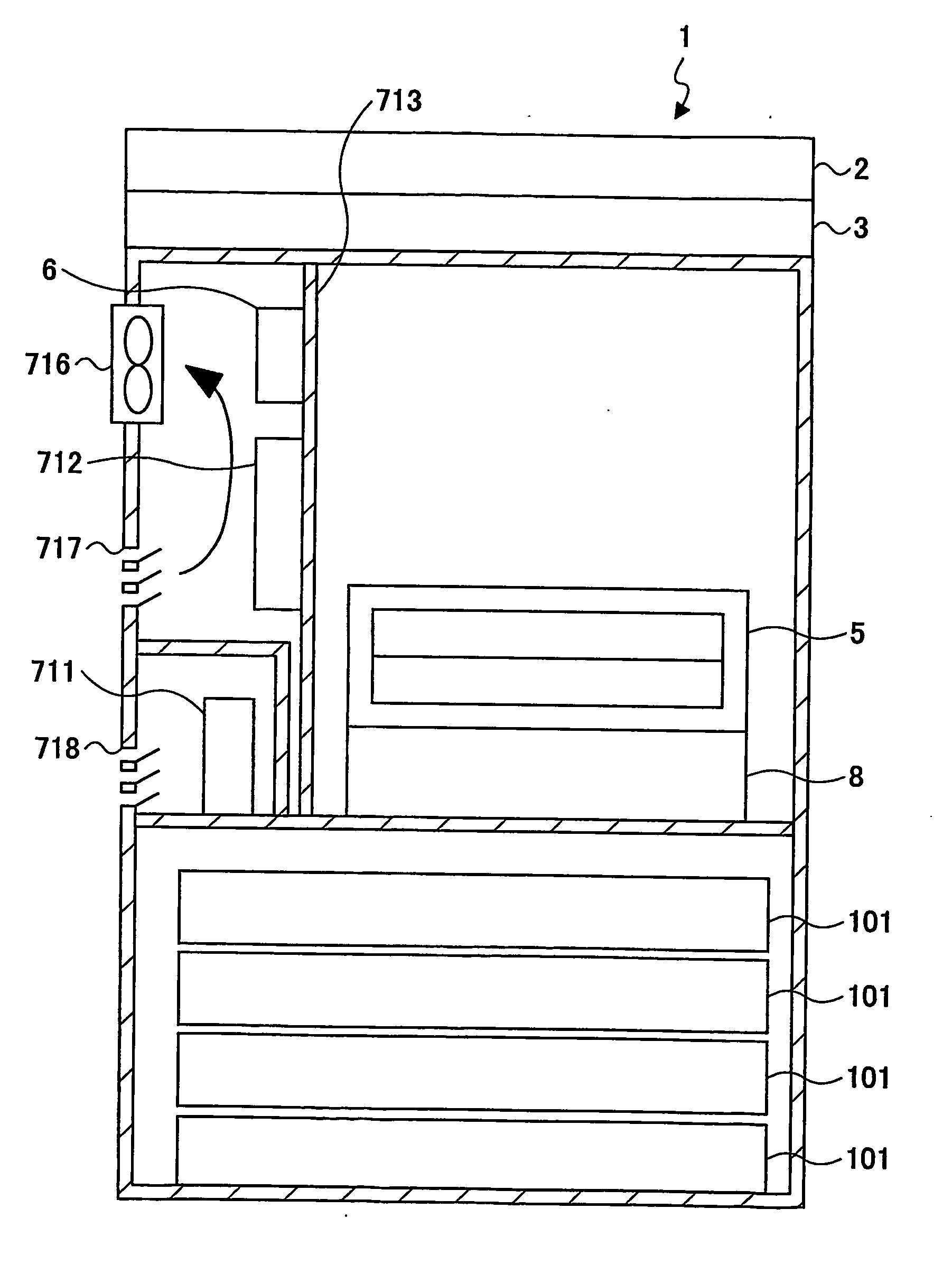

Image forming apparatus another secondary power supply

ActiveUS20060024078A1Prevent moisture condensationAvoid temperature riseElectrographic process apparatusControl theoryImaging equipment

An image forming apparatus (1) is disclosed, including: a fixing unit (5); a main power supply (6) that provides a portion of the heaters with voltage; and a secondary power supply (711, 712) that provides another portion of the heaters connected to the portion of the heaters in parallel with power provided by the main power supply. The secondary power supply is disposed below and in the neighborhood of the fixing unit. An electric double layer capacitor (711) of the secondary power supply may be disposed between a side face of a chassis of the image forming apparatus and a thermally insulting wall (713) towards the fixing unit, or at an exterior of the chassis of the image forming apparatus on the side face of the chassis. The secondary power supply thus will not be heated by the fixing unit.

Owner:RICOH KK

Method for filling bilateral parts beside pillar with repeatedly-mined left-over coal pillars in residual mining area

ActiveCN105545309AGuaranteed safe recoveryReduce resource requirementsSolid waste managementUnderground miningMining engineeringCoal pillar

The invention discloses a method for filling bilateral parts beside a pillar with repeatedly-mined left-over coal pillars in a residual mining area. According to the invention, on the basis of exploration and identification of the left-over coal pillars in the residual mining area, the distributive locations and sizes of pillar mining areas, lateral protection of the left-over coal pillars in the residual mining area are successively carried out by using a sectioned filling method for the bilateral parts beside the pillar; a conveyor gateway and an air return gateway are dug in bilateral filling bodies beside the pillar; and short-wall mechanization working faces are arranged for repeated mining of the left-over coal pillars in the residual mining area. The method provided by the invention makes full use of the left-over coal pillars in the residual mining area, alleviates contradiction between finiteness of coal resources and infiniteness of consumer demands, avoids transient instability, domino instability or other dynamic disasters caused by coal pillars left by pillar mining under action of long-term creep effect, and guarantees safe repeated mining of the left-over coal pillars in the residual mining area by using the bilateral filling bodies beside the pillar.

Owner:TAIYUAN UNIV OF TECH

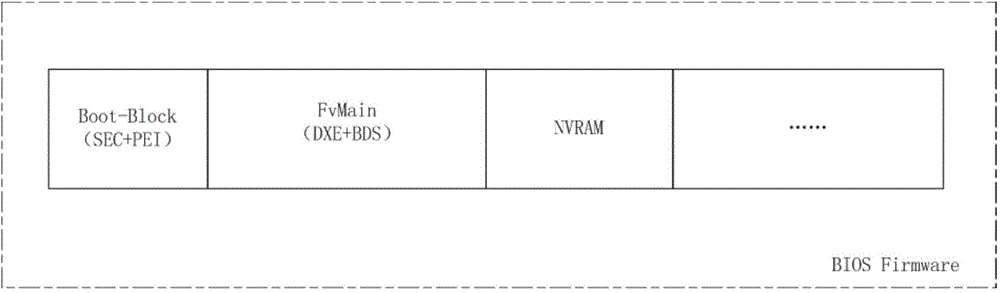

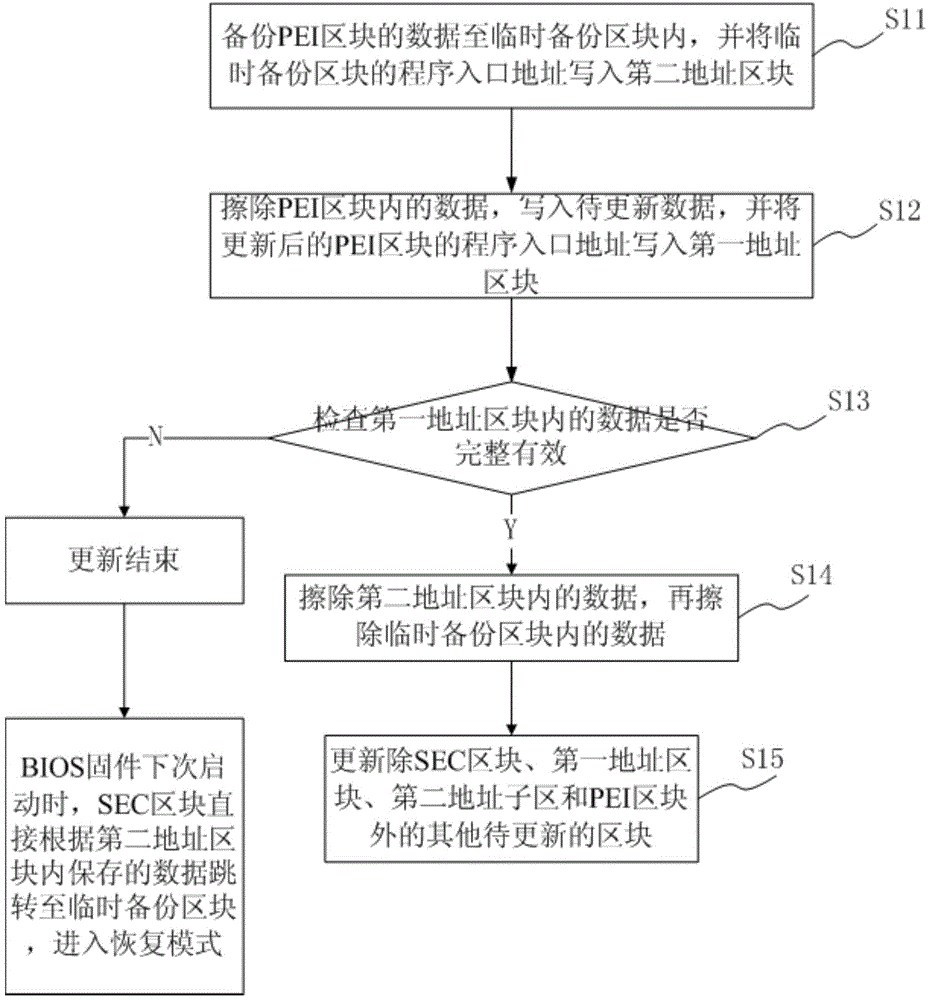

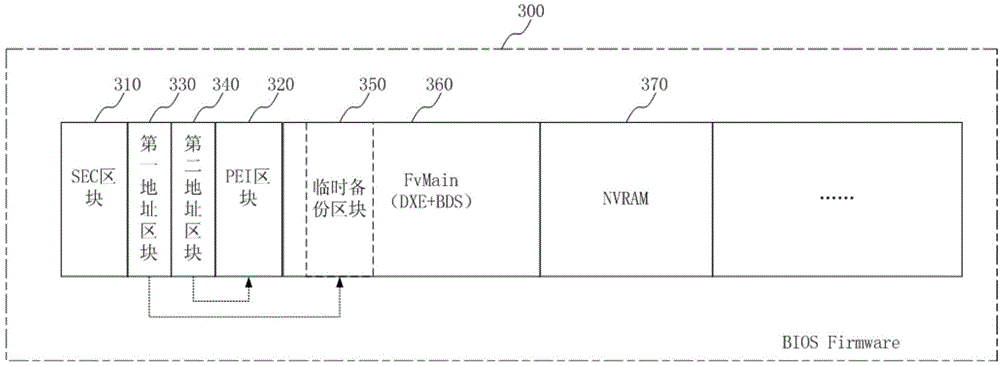

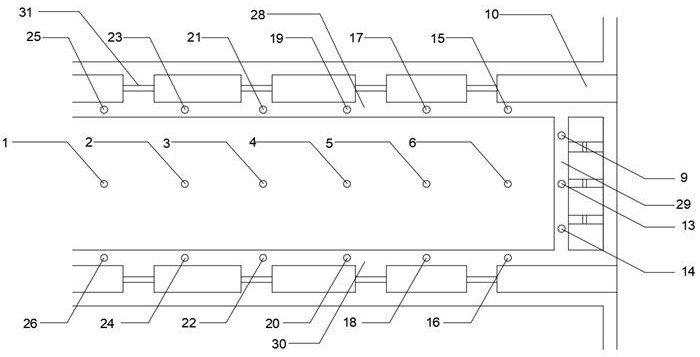

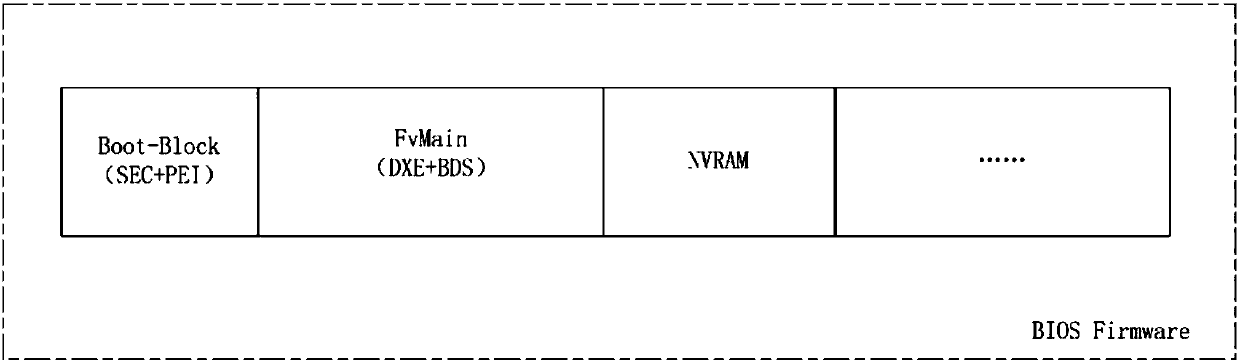

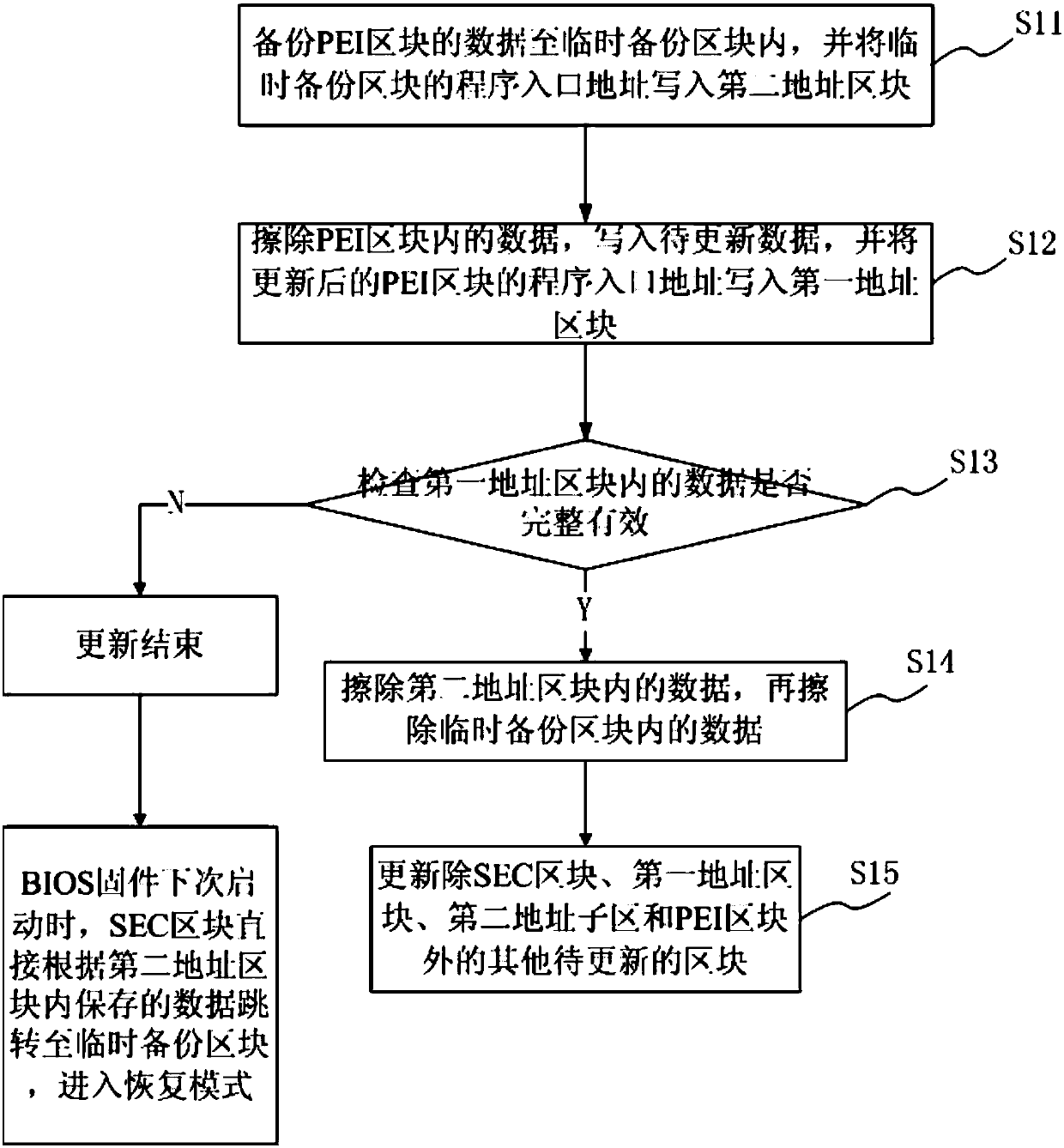

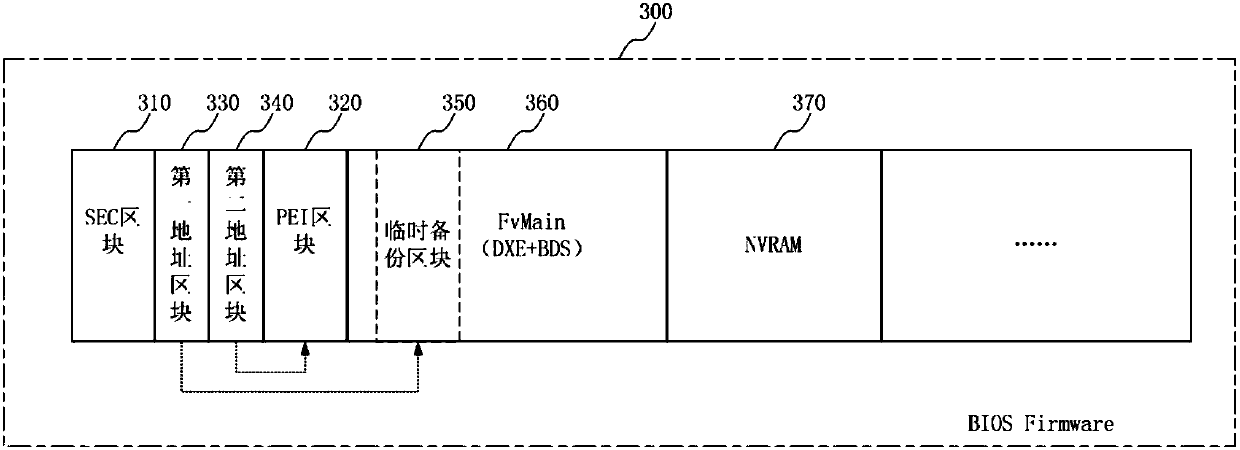

BIOS firmware dividing and updating method and system

ActiveCN104573529AGuaranteed safe recoveryImplement Security UpdatesPlatform integrity maintainanceSoftware deploymentSoftware engineeringBIOS

The invention provides BIOS firmware dividing and updating method and system. The dividing method includes: dividing a Boot-Block into an independent SEC block and a PEI block, and adding a first address block and a second address block. The safety updating method of BIOS firmware includes: backing up PEI block data to a temporary backup block, and writing the program inlet address of the PEI block data into the second address block; updating the PEI block data, and writing the program inlet address of the PEI block data into the first address block; inspecting the data of the first address block, erasing the data of the second address block and the temporary backup block if the data of the first address block is valid, and continuing to update; and finishing the updating if the data of the first address block is invalid. When the BIOS firmware starts again, the SEC block skips to the temporary backup block according to data saved in the second address block and enters a recovery mode. The method has the advantages that the BIOS firmware updating does not rely on specific hardware support, and the method is wide in application range and simple and safe to realize.

Owner:CELESTICA TECH CONSULTANCY SHANGHAI

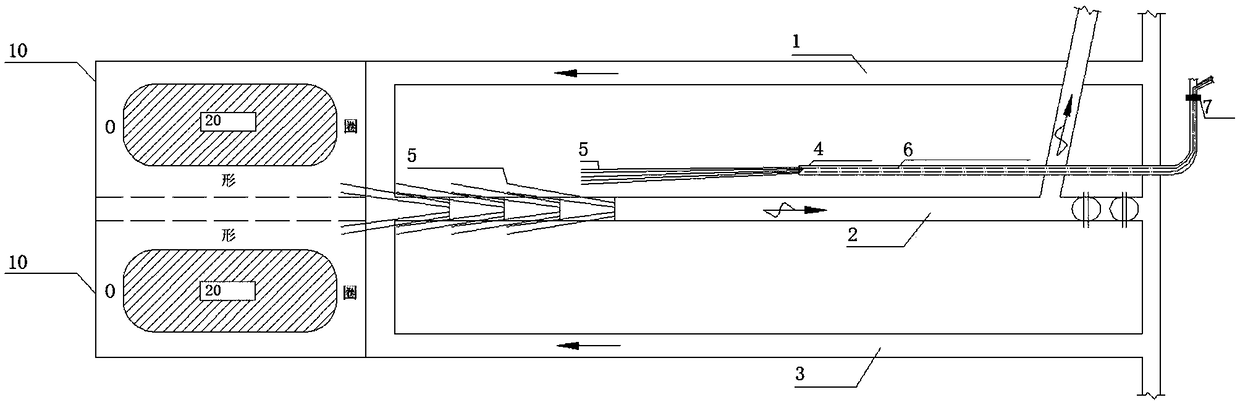

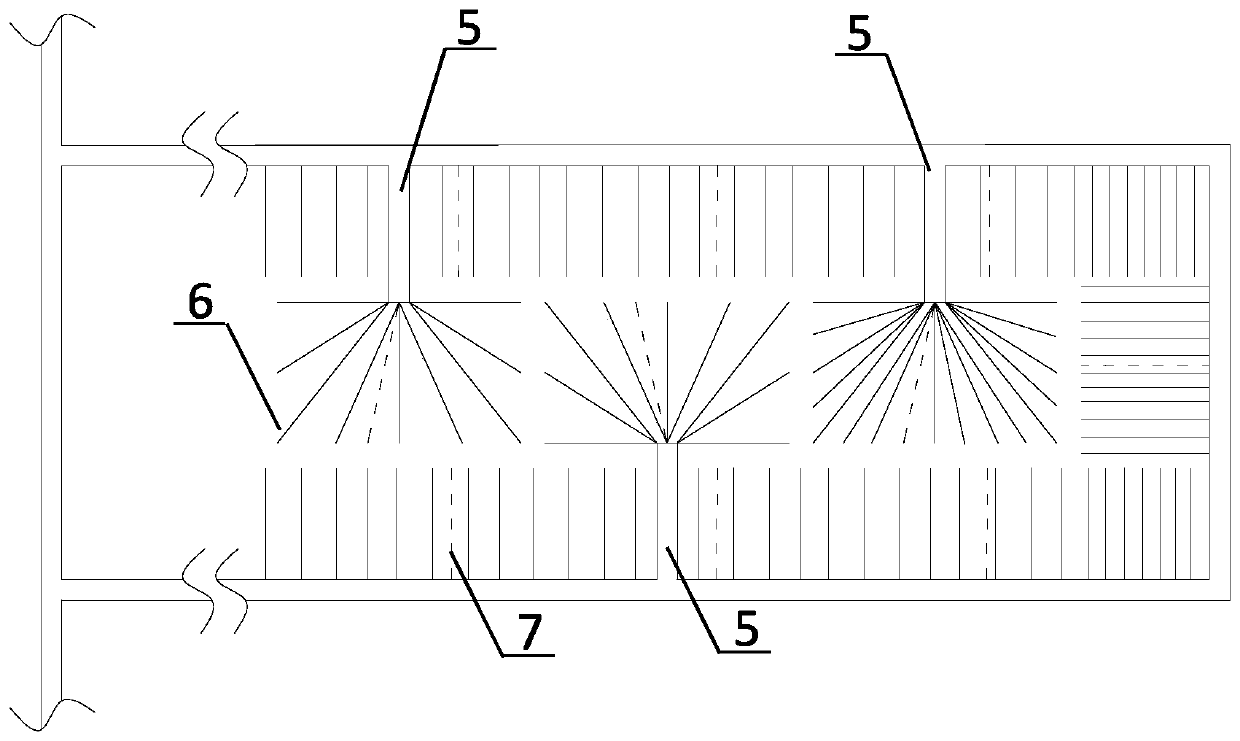

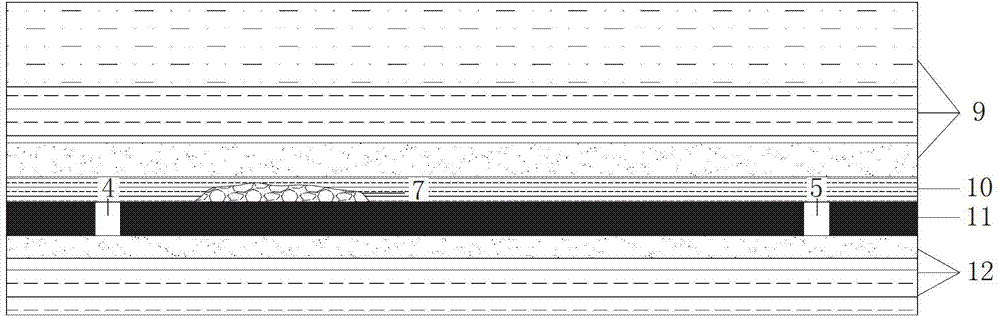

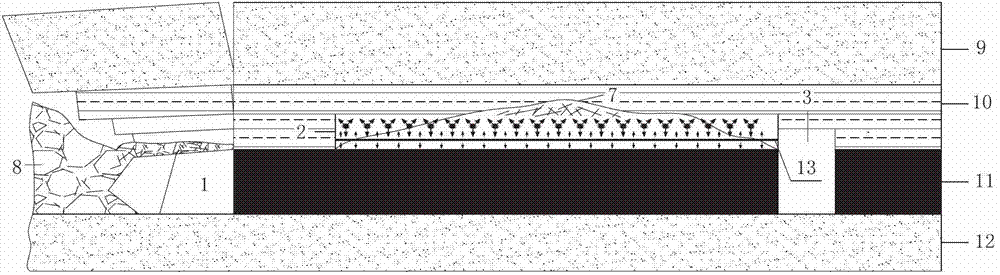

Parallel digging, mining and filling operation coal mining method for controlling overlaying strata fracture and surface subsidence

InactiveUS20180195386A1Guaranteed safe recoveryQuantity minimizationUnderground miningSurface miningCoal miningMineralogy

Disclosed is a parallel digging, mining and filling operation coal mining method, in which a stope haulage roadway, stope branch roadways, and two-winged adits are arranged in a stope. The stope haulage roadway and the stope branch roadways serve as haulage passages, and coal mining work is carried out in the two-winged adits. All two-winged adits are mined sequentially and filled timely, and coal mass that has not been mined or two-winged adits that have been filled always exist at the two sides of the two-winged adit that are being mined, to support and control the roof. The two-winged adits can be mined without support or with less supports by controlling the length of the two-winged adits and the number of two-winged adits filled in one time, whereupon pillar-free mining can be realized.

Owner:CHINA UNIV OF MINING & TECH

Fluid collecting apparatus

ActiveUS20150246806A1Safe collectionAvoid lossFuel feedersOther washing machinesEngineeringFluid Leak

Owner:NAT DISASTER MANAGEMENT INST

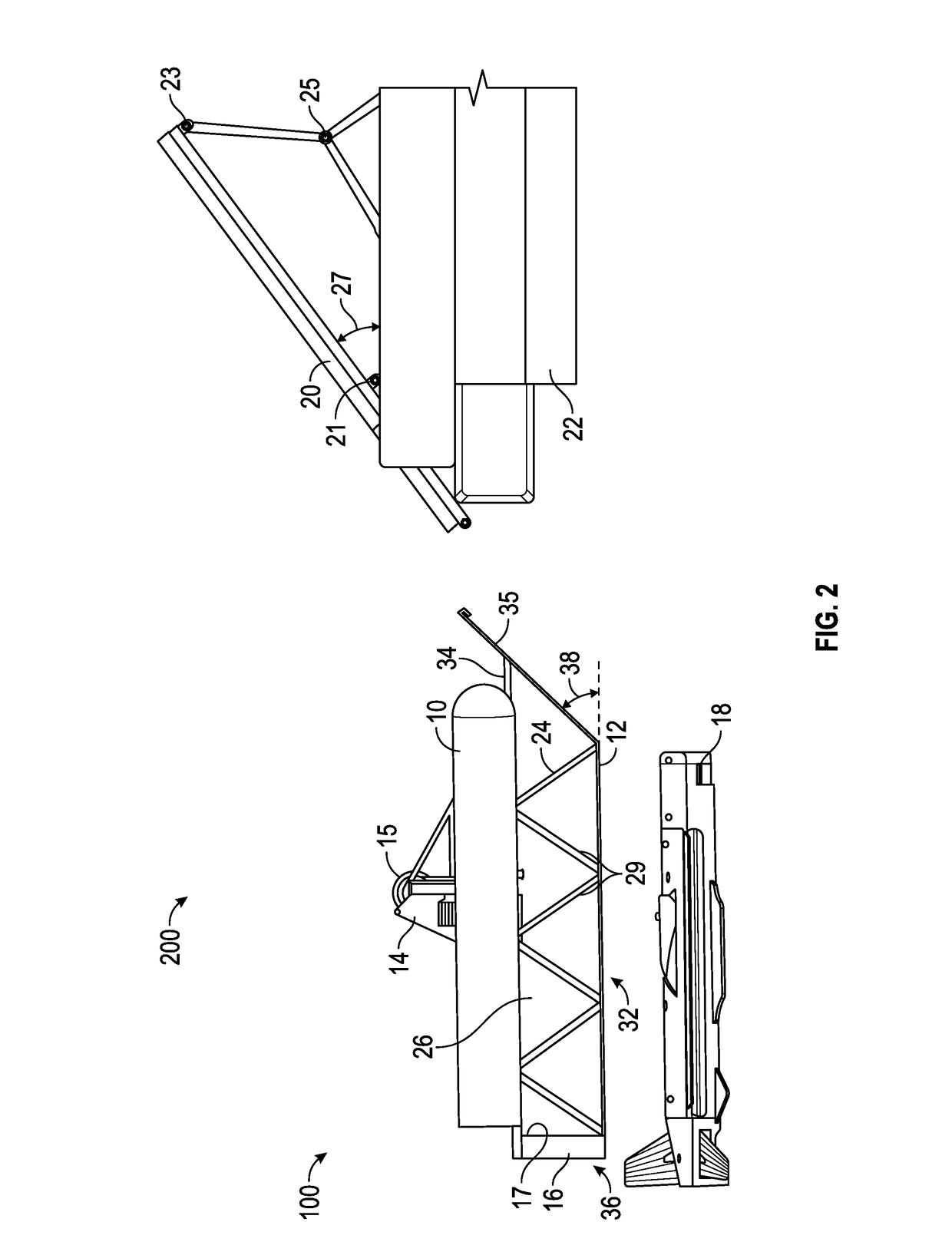

System for the deployment and recovery of towed sensors

InactiveUS9598149B1Guaranteed safe recoveryReduce capacityTowing/pushing equipmentCargo handling apparatusEngineeringSponson

A Towed Body Recovery Drone facilitates the safe recovery of fragile towed sensors by surface craft. The TBRD comprises a buoyant sponson section sized to give the TBRD minimal buoyancy necessary to keep the sensor on the surface in a static condition. Structural elements and skids are arranged to protect the sensor from impact with rigid objects and allow the TBRD to be pulled aboard a surface craft by means of a ramp structure. A capture device manages the sensor's tow cable and restrains the sensor within the TBRD structure.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

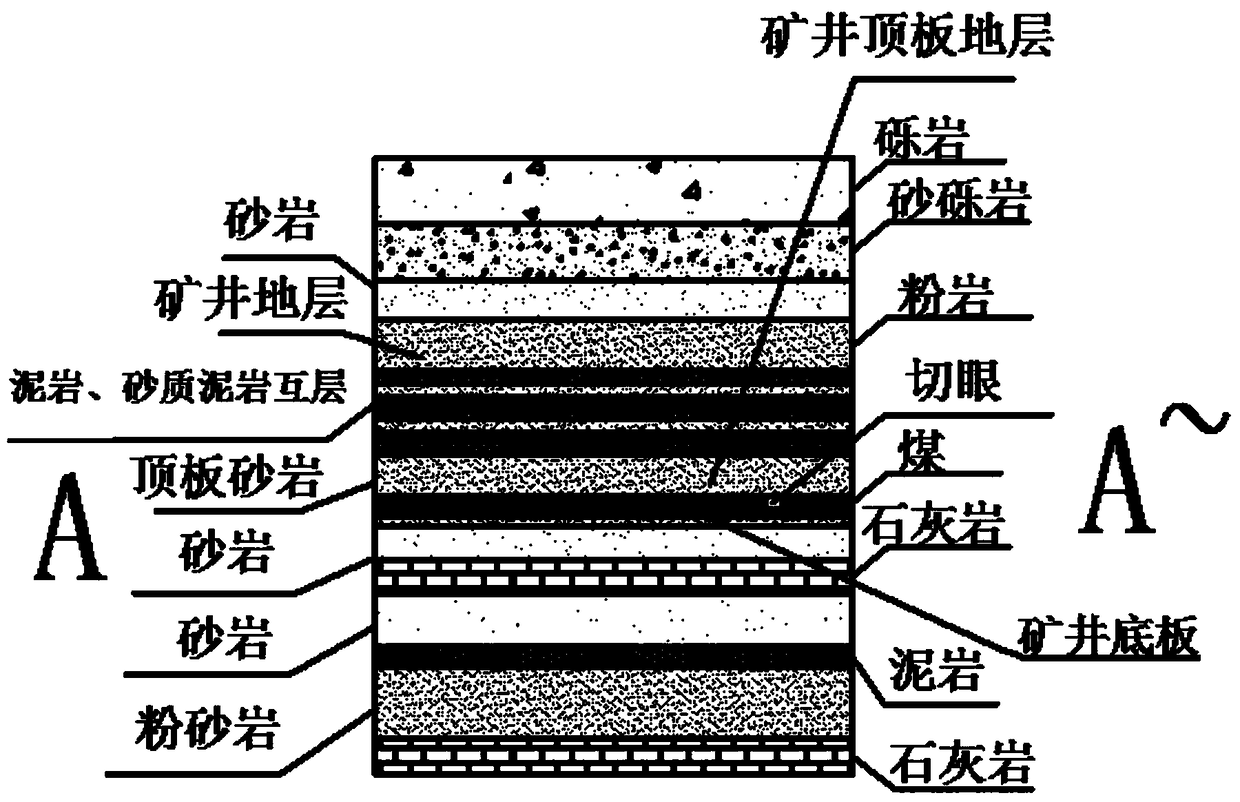

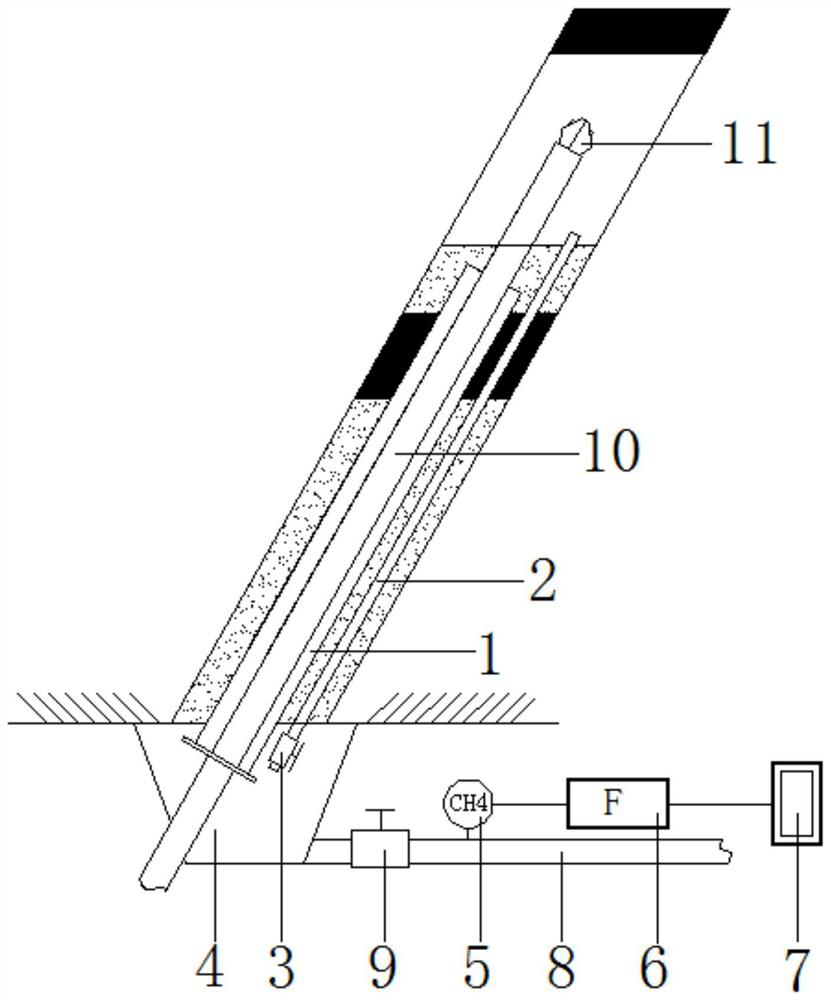

Single and low-air-permeability coal bed gas control method

The invention belongs to the field of underground safety and particularly relates to a single and low-air-permeability coal bed gas control method. By combining high position lane pumping with high position drilling to conduct comprehensive control on goaf gas and by combining a half-coal tunnel with low position drilling to control corner gas on a working face, a gas comprehensive control method suitable for a single and low-air-permeability coal bed is achieved, and safe extraction of the coal bed working face is ensured. The single and low-air-permeability coal bed gas control method is simple and easy to use and good in gas control effect.

Owner:山西潞安环保能源开发股份有限公司常村煤矿

Extraction method for unloading gas in goaf bed separation zone of ultra-long working face

ActiveCN109026133ASolve overrunEasy to drawTunnel/mines ventillationGas removalHigh concentrationEngineering

The invention discloses an extraction method for unloading gas in a goaf bed separation zone of an ultra-long working face and treating top corner and goaf gas. The method comprises the following steps that an upper gate backstopping tunnel, a middle gate backstopping tunnel and a lower gate backstopping tunnel are arranged for the ultra-long working face to form a 'W'-shaped ventilation system ofupper gate air inlet, lower gate air inlet and middle gate air return; after a high-level extraction drill and a high-level drainage tunnel are arranged at the middle-upper portion in an 'O'-shaped circle of the upper portion of middle gate goaf zone cover rock, backstopping is carried out; the high-level extraction drill and the high-level drainage tunnel are connected to an extraction branch pipe, and the extraction branch pipe is merged into a mine gas extraction utilization system for extraction control. The extraction method can efficiently extract and utilize high-concentration gas in an unloading fissure zone of the goaf bed separation zone, reduce the gas emission amount in the goaf zone of the working face, eradicate working face air return, top corner gas exceeding and goaf zonegas explosion accidents, improve the working face production efficiency and safety and ensure mine safe backstopping.

Owner:SICHUAN HUAYINGSHAN LONGTAN COAL

Method for recovering room-type coal pillars by cemented filling of reserved roadways

ActiveUS20210355826A1Reduce workloadImprove securityUnderground miningSurface miningMining engineeringStructural engineering

Provided is a method for recovering room-type coal pillars by cemented filling of reserved roadways, which is especially suitable for safe and efficient recovery of left coal pillars in room-type mining faces in mining areas where the ecological system is fragile, such as in western China. In the method, by constructing reserved roadways in two adjacent rows of room-type goafs, excavating coal pillar roadways in room-type coal pillars, and finally interconnecting the reserved roadways with the coal pillar roadways to form a U-shaped working face, room-type left coal pillars are recovered. Thus, not only the workload of roadway excavation is reduced, but also the recovery ratio of the coal resources is maximized. The method provides a novel technical model for the recovery of room-type left coal pillars in mining areas, such as in western China.

Owner:CHINA UNIV OF MINING & TECH

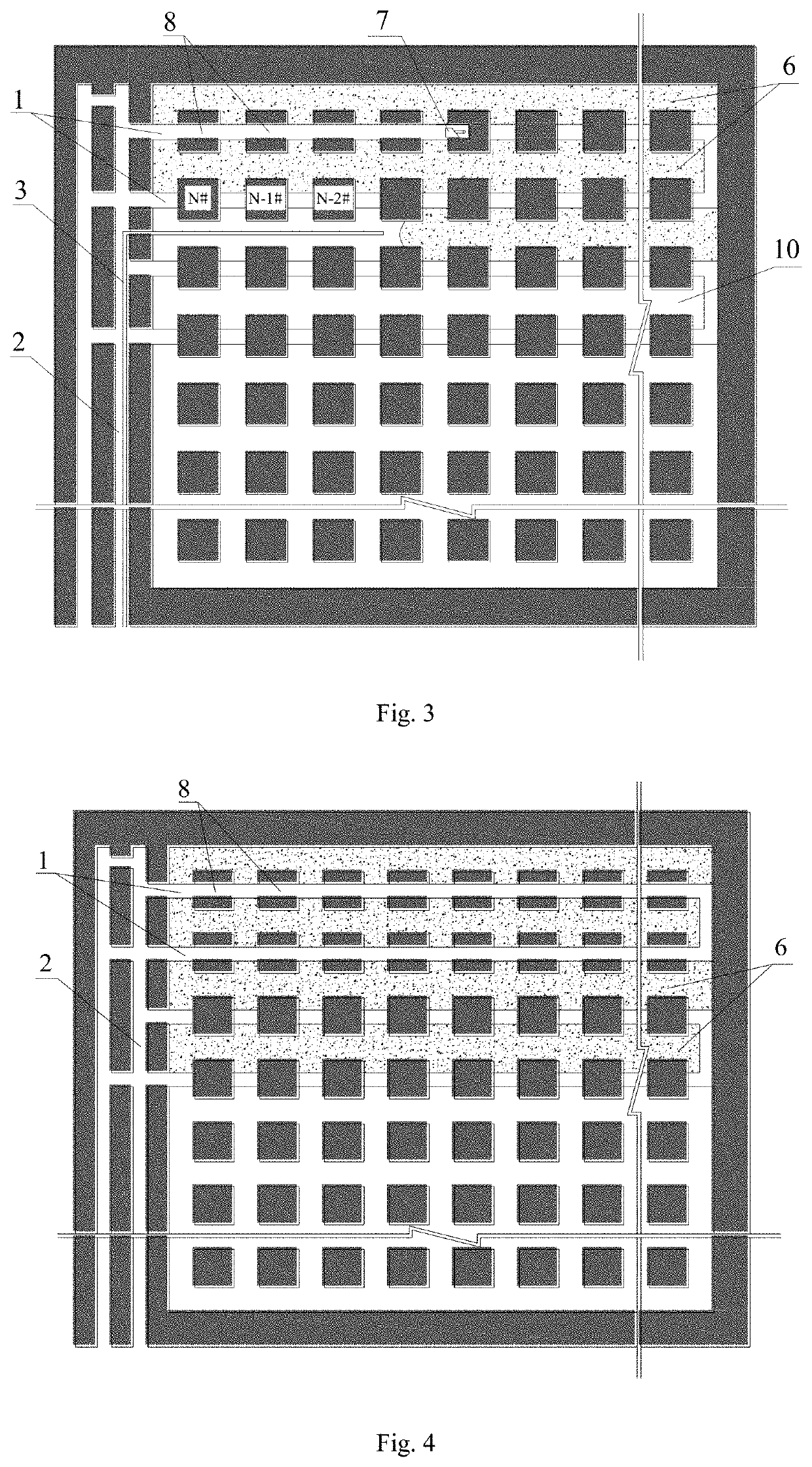

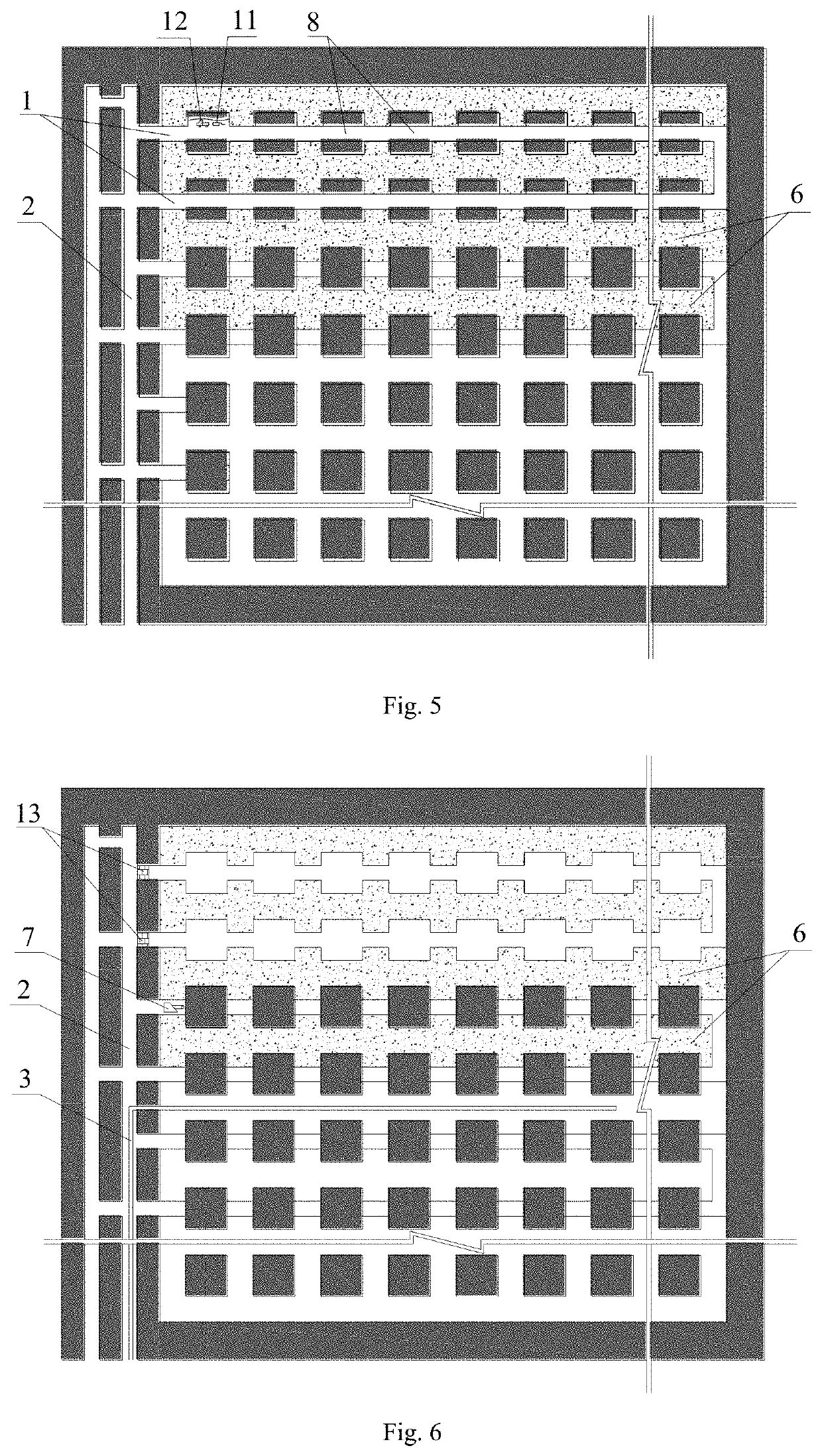

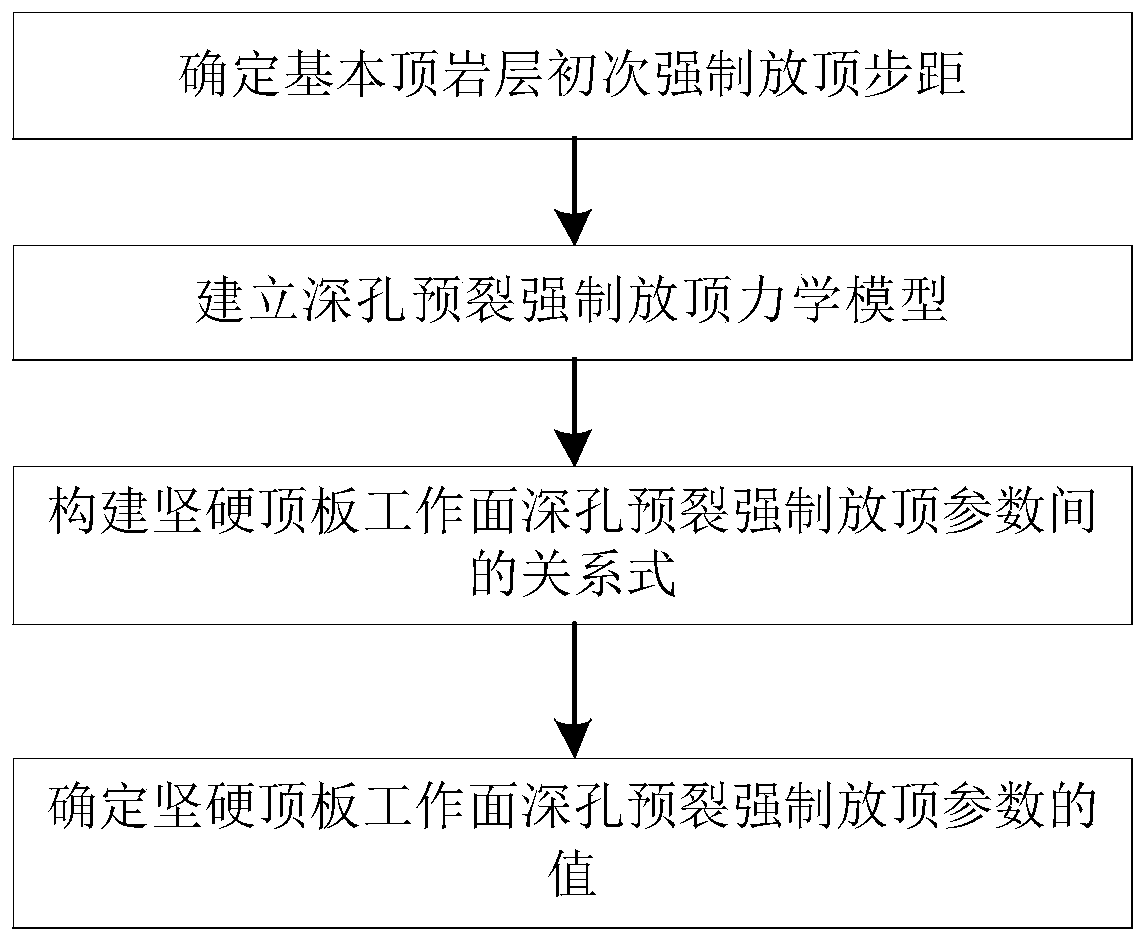

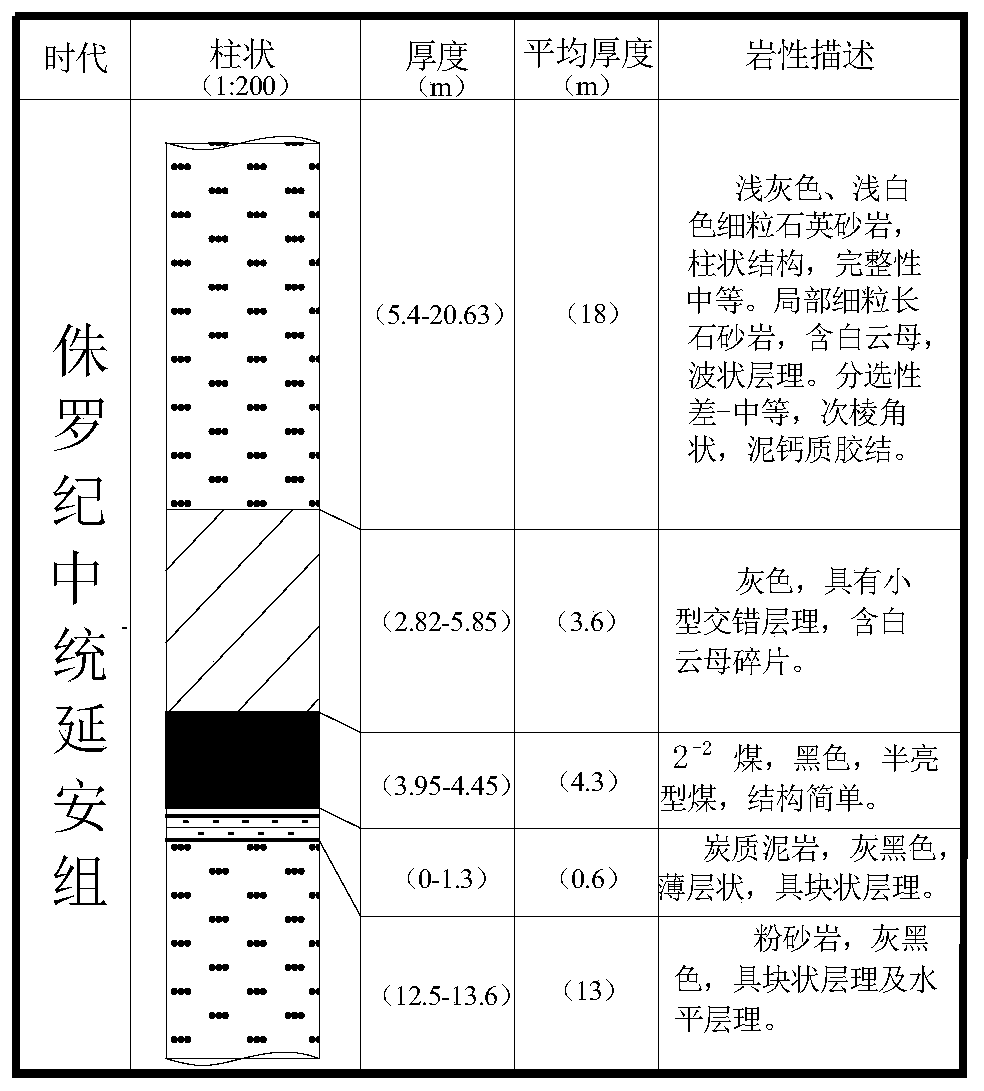

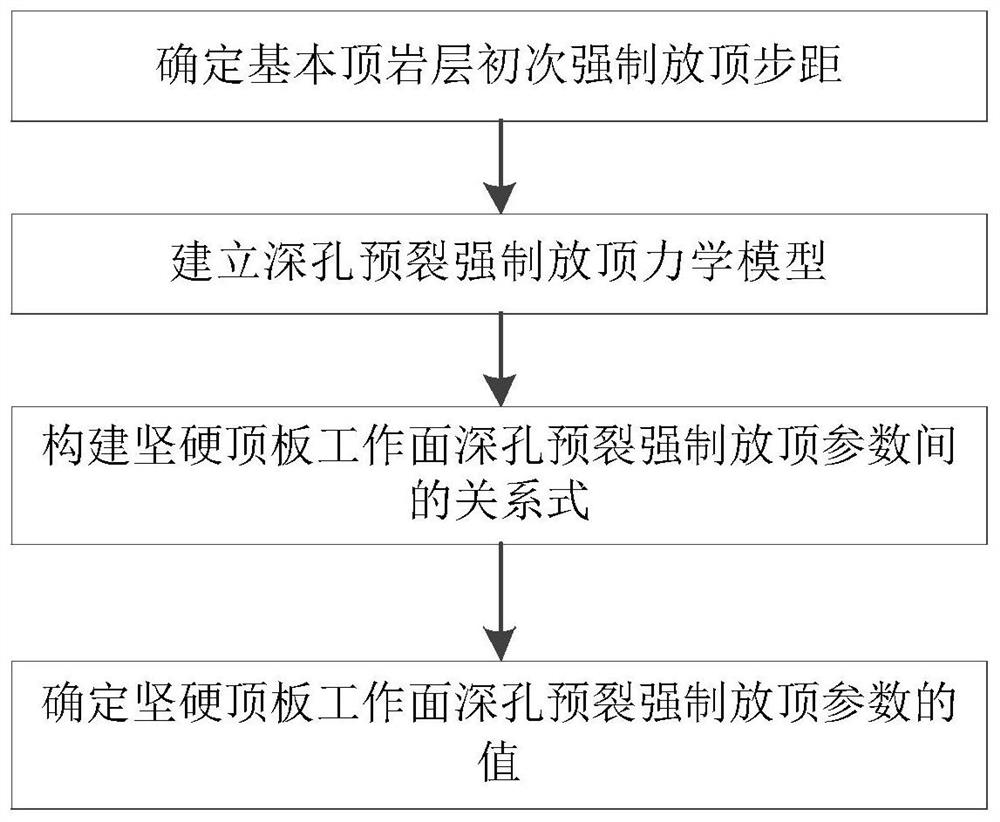

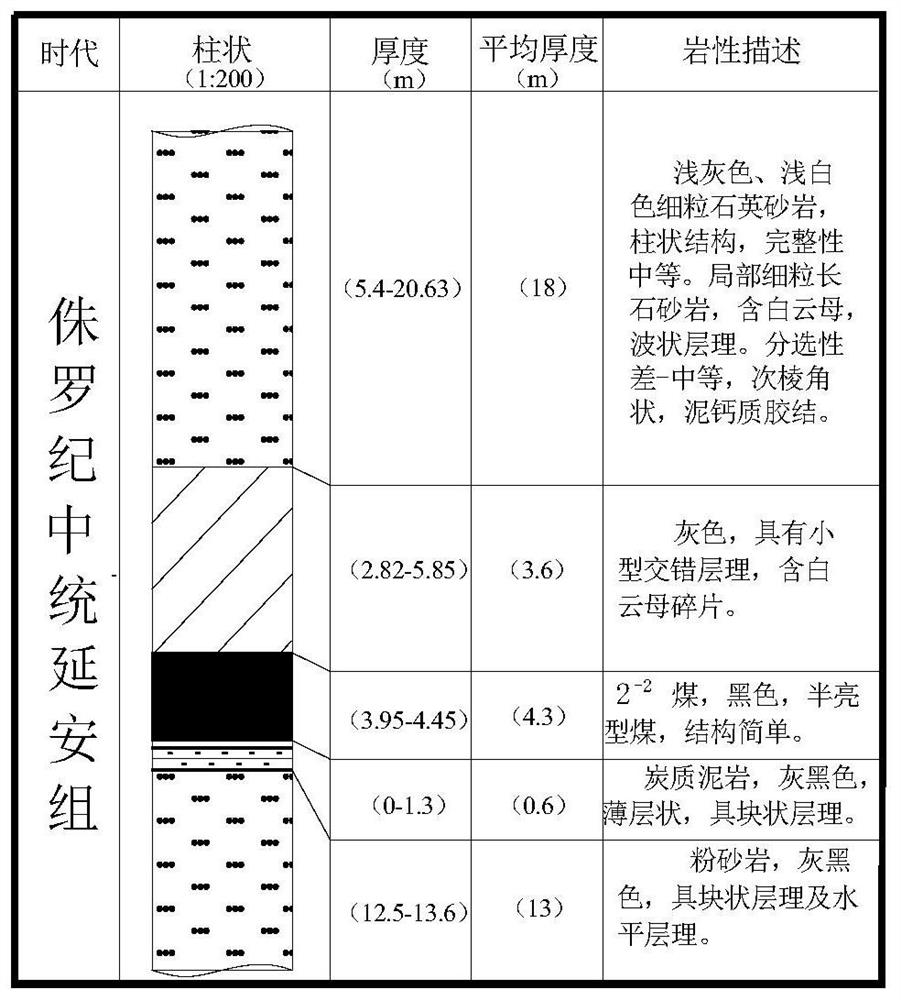

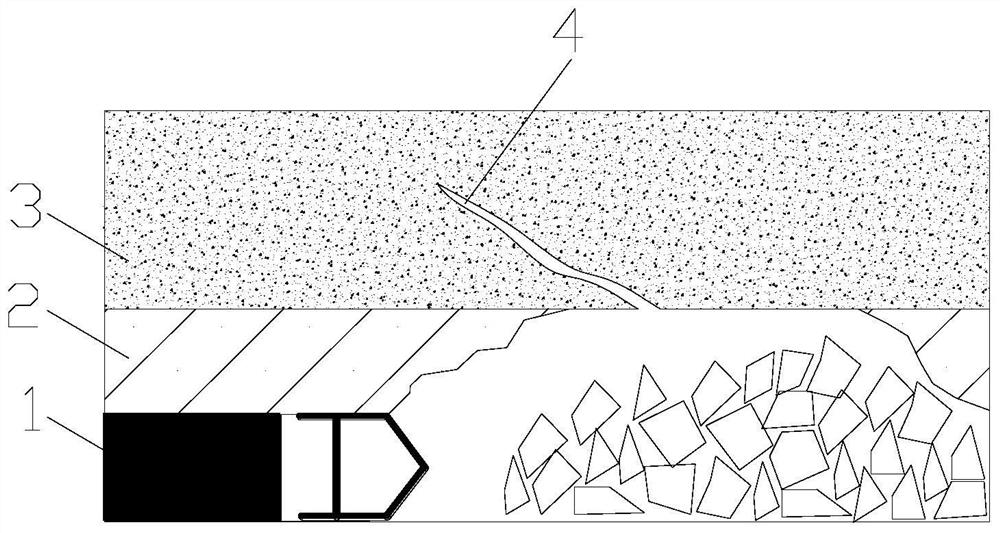

Method for determining hard roof working face deep hole pre-cracking forced roof caving parameter

ActiveCN110748342ADetermining the step distance of the first forced top downGuaranteed safe recoveryMining devicesData processing applicationsFracture mechanicsMechanical models

The invention discloses a method for determining a hard roof working face deep hole pre-cracking forced roof caving parameter. The method comprises the following steps of 1, determining the initial forced roof caving step distance of a basic roof rock stratum (3); 2, establishing a deep hole pre-cracking forced roof caving mechanical model; 3, constructing a relationship between the hard roof working face deep hole pre-cracking forced roof caving parameters; and 4, determining the value of the hard roof working face deep hole pre-cracking forced roof caving parameter. According to the characteristics of the initial mining pre-cracking fracture in the basic roof rock stratum, a deep-hole pre-cracking forced roof caving model is established, the initial breaking distance of the basic roof isdeduced by using a fracture mechanics theory, a deep-hole pre-cracking forced roof caving parameter is determined, and a theoretical reference is provided for a coal mine hard roof forced roof cavingparameter design research.

Fluid collecting apparatus

ActiveUS9434600B2Safe collectionAvoid lossFuel feedersLiquid transferring devicesEngineeringFluid Leak

Owner:NAT DISASTER MANAGEMENT INST

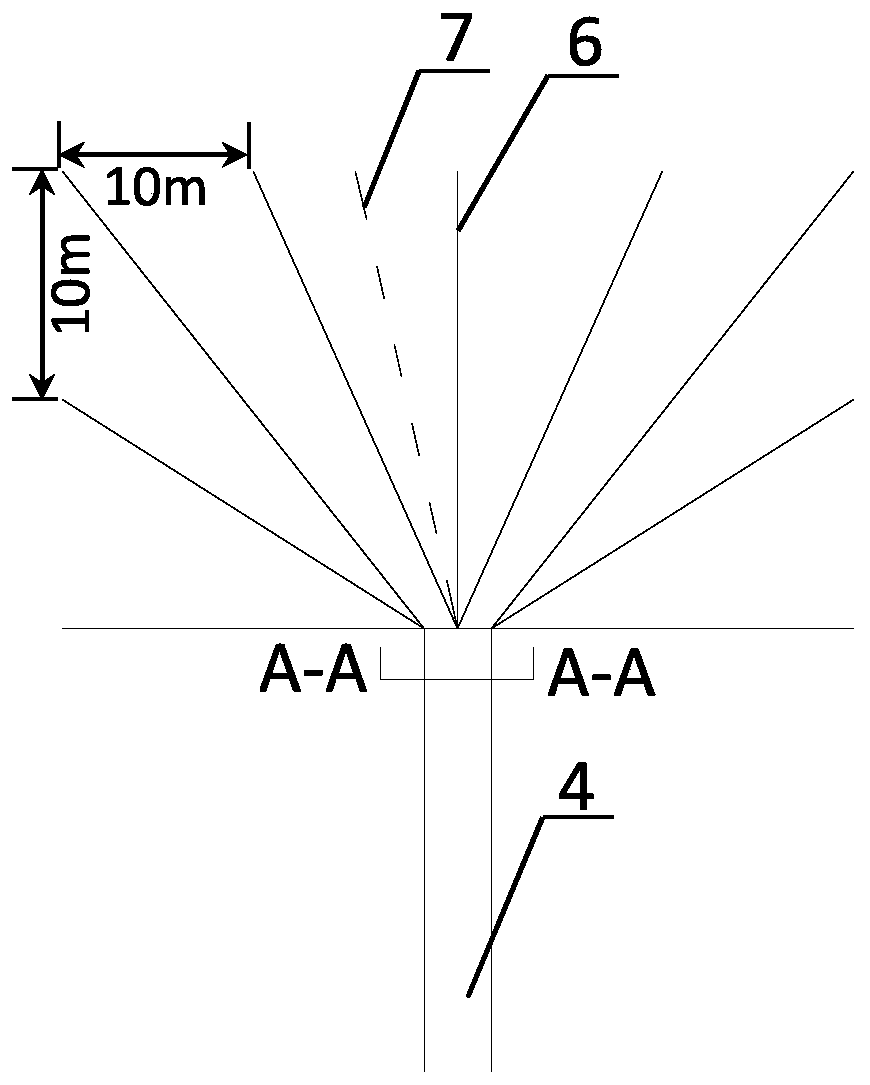

Gas drainage method on working face of thin coal seam with low gas permeability

ActiveCN109944630AGuaranteed safe recoveryGuaranteed Extraction EffectGas removalProcess engineeringDrill

The invention provides a gas drainage method on a working face of a thin coal seam with low gas permeability. The working face is divided into an adjacent mining roadway evaluation unit, an adjacent cutting hole roadway evaluation unit and a working face middle evaluation unit; different bedding gas extraction drill arrangement methods are adopted for different evaluation units, finally bedding gas extraction drills are connected with gas extraction pipelines, coal-seam gas in each evaluation unit in the working face is extracted under the action of negative pressure, gas inspection drills areconstructed in each evaluation unit, the gas extraction effect is inspected, the method better solves the problem that gas extraction is substandard due to the fact that the gas extraction drills areeasily inclined to a top plate or a bottom plate due to the thin coal seam, poor air permeability and large length of the working face, the effective utilization ratio of the gas extraction drills isincreased, the target rate of gas extraction of the coal seam in the middle of the working face is increased, and safe mining of the working surface is ensured.

Owner:HENAN POLYTECHNIC UNIV

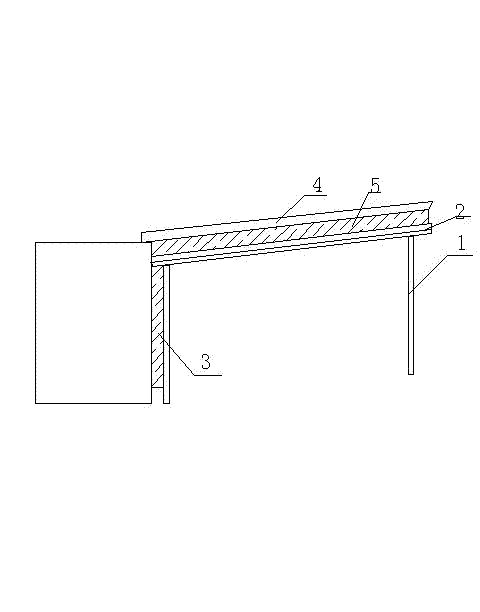

Leakage-proof stope face roof

InactiveCN103046939AImprove support qualityGuaranteed safe recoveryMine roof capsRelative displacementCoal

The invention relates to a leakage-proof stope face roof comprising supporting columns arranged at an interval and a beam erected on the supporting columns. The bottoms of the supporting columns are fixed on a tunnel bottom plate, the beam is fixedly arranged at the tops of the supporting columns, a filling buttress is filled between one side, facing the side wall of a tunnel, of one supporting column and the supporting column, the upper side of the beam faces a top plate of a tunnel, and fillers are filled between the beam and the top plate. The stope face protection roof is capable of improving supporting quality and guaranteeing stoping safety, cohesive force and an internal friction angle between a fracture and a coal-rock mass are increased by means of erecting a Malisan material layer, resistance of relative displacement between the inside of a rock mass and a stope face is increased, and integral stability of the coal-rock mass and stoping safety are improved.

Owner:辛慰

Method for detection and prevention of sandstone fissure water in roof sandstone of fully mechanized caving mining face with large mining depth and large span

InactiveCN104481587BGuaranteed safe recoveryEliminate the threat of water damageMining devicesGeological measurementsLong spanCoal

Owner:XIAN UNIV OF SCI & TECH +1

Method for making natural gas by underground coal bed microorganism

InactiveCN101922287BWill not cause pollutionImprove breathabilityConstructionsCoal gasificationProduct gasProcess engineering

Owner:江苏君东新材料科技发展有限公司

Method for extracting top coal gas during fully-mechanized top coal caving period of extra-thick coal seam

PendingCN113653527ASolve the overrun problemReduce influxMining devicesDirectional drillingMining engineeringCoal mine methane

The invention relates to the technical field of coal mine gas extraction, and discloses a method for extracting top coal gas during a fully-mechanized top coal caving period of an extra-thick coal seam. The method comprises the following steps of (1) designing bedding directional long drilling parameters: designing the bedding directional long drilling parameters according to coal seam occurrence conditions and firmness coefficients; (2) conducting directional drilling construction, specifically, conducting bedding directional long drilling on the coal seam before working face stoping, connecting a pipeline to a hole opening, and the pipeline is connected with negative pressure extraction equipment; (3) crushing the top coal: repeatedly supporting and extruding the top coal by a bracket of a stope face to generate cracks in the coal seam, and continuously desorbing the gas in the coal seam; and (4) conducting top coal caving: during the top coal caving period, a large amount of gas rushes to the top of the working face and is continuously pumped out through a drill hole. The method solves the problem that a large amount of desorbable gas generated in the coal caving period cannot be effectively extracted in time through a coal seam roof high-position drilling hole or a high drainage roadway, the desorbable gas instantly flows into the working face, so that the gas of an upper corner or a return airway exceeds the limit.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

A Method for Determining Parameters of Deep Hole Pre-cracking Forced Caving in Hard Roof Working Face

ActiveCN110748342BDetermining the step distance of the first forced top downGuaranteed safe recoveryMining devicesData processing applicationsFracture mechanicsMechanical models

The invention discloses a method for determining a forced caving parameter for a deep hole pre-split on a working face of a hard roof. The method comprises the following steps: step 1: determining the initial forced caving step distance of a basic top rock layer (3); step 2, establishing The mechanical model of forced caving for deep hole pre-splitting; Step 3: Construct the relational expression between the parameters of forced caving for deep hole pre-splitting in the working face of hard roof; . According to the characteristics of the initial mining pre-split cracks in the basic top rock layer, the invention establishes a deep hole pre-split forced roof caving model, uses the fracture mechanics theory, deduces the initial breaking distance of the basic roof, determines the deep hole pre-split forced roof caving parameters, and is a coal mine. A theoretical reference is provided for the design and study of the parameters of the forced caving of the hard roof.

Owner:XIAN UNIV OF SCI & TECH

A device and method for determining the horizon of gas-occurring rock formations in overlying rock strata

ActiveCN111255509BSure easyGuaranteed safe recoveryMining devicesGas removalMining engineeringGas concentration

A device and method for determining the stratum of gas-occurring rock formations in an overlying rock stratum. The device includes a grouting protection pipe, a grout return pipe, a gas collection hood, a drainage pipeline, a gas concentration probe, a substation, and a downhole tablet computer. The gas collection hood is installed at the hole of the borehole, and a grouting protection pipe and a grout return pipe are arranged in the borehole. The gas collection hood is connected to one end of the extraction pipeline through a flange. A second stop valve and a gas concentration probe are installed on the drainage pipeline, and the second stop valve is set closer to the gas collection hood than the gas concentration probe. The station is connected to the downhole tablet computer, and the other end of the drainage pipeline is connected to the drainage supervisor. The device is simple in structure, easy to operate and low in cost. It can simply and effectively determine the stratum where the gas occurs, and provides solid data support for optimizing the extraction parameters. Safe recovery.

Owner:LIAONING TECHNICAL UNIVERSITY

Comprehensive low-voltage ride-through method for doubly-fed wind turbines based on stator series dynamic reactance

ActiveCN108879779BProtection is in progressReduce peak currentSingle network parallel feeding arrangementsWind energy generationTransient stateControl engineering

Owner:TIANJIN UNIV

Method for ensuring safe stoping of working face under old fire area of shallow-buried close-distance coal seam group

PendingCN114508352APrevent spontaneous ignitionPrevent intrusionUnderground miningDust removalStructural engineeringSlurry

The invention relates to the field of fire prevention and control, in particular to a method for guaranteeing safe stoping of a working face under an old fire area of a shallow-buried short-distance coal seam group. Comprising the following steps. And S100, digging a stope face of the lower coal group of the shallow-buried close-distance coal seam group, and drilling a plurality of groups of observation-exhaust holes towards the old fire area in the air inlet crossheading, the air return crossheading and the open-off cut of the lower coal group after the stope face is arranged. S200, before working face stoping, a plurality of sets of ground nitrogen injection-grouting holes are formed in the position, located between an air inlet way and an air return way, over the working face from the ground to the old fire area. And S300, before working face stoping, liquid nitrogen is poured into the old fire area from the ground nitrogen injection-grouting holes, fire sources possibly existing in the old fire area are extinguished through liquid nitrogen injection, the goaf is inerted, and the pressure difference between the goaf and the ground is balanced. And S400, after exhausting is finished, working face stoping is conducted, slurry is poured into the old fire area from the ground nitrogen injection-grouting hole, grouting is stopped till the ground nitrogen injection-grouting hole is located above the goaf suffocation zone, and stope cracks are blocked through the slurry.

Owner:TAIYUAN UNIV OF TECH

Method and system for dividing and updating bios firmware

ActiveCN104573529BGuaranteed safe recoveryImplement Security UpdatesPlatform integrity maintainanceSoftware deploymentBIOSBackup

Owner:CELESTICA TECH CONSULTANCY SHANGHAI

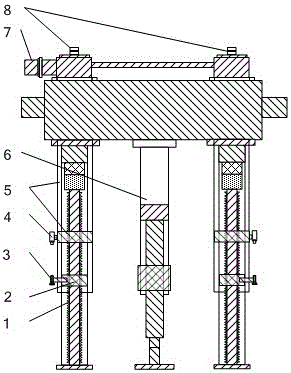

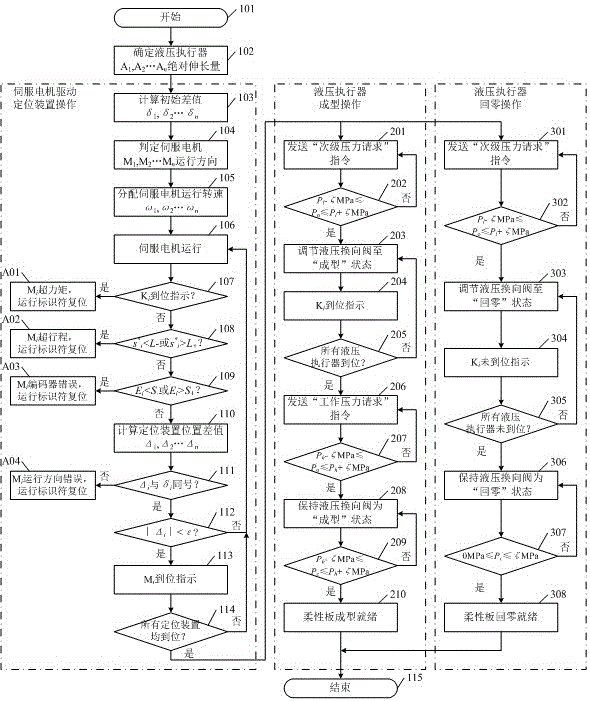

Mechanical-electrical-liquid integration control method for multi-actuator system

ActiveCN106424227AChange controlGuaranteed molding accuracyServometer circuitsFluid-pressure actuator componentsHydraulic cylinderElectric machine

The invention provides a mechanical-electrical-liquid integration control method for a multi-actuator system. The mechanical-electrical-liquid integration control method comprises the following steps: firstly, determining absolute elongations, corresponding to hydraulic actuators, of all action points according to a curvature requirement of a controlled object; secondly, driving a positioning device to safely and accurately operate to reach within an error range of a target value by a servo motor; thirdly, controlling all the hydraulic actuators to perform gradual forming or restoring operation on the controlled object by adjusting a hydraulic direction-changing valve; meanwhile, constraining all operation steps by corresponding safety interlocking control logics; and finally, finishing forming and restoring by the controlled object according to the requirements. The method provided by the invention can be suitable for a control system which adopts a hydraulic cylinder as the actuator, drives the positioning device for accurate positioning by the servo motor and is used for bending special metal flexible plates with fixed lengths; and by means of an integration control method, an existing metal plate bending and forming control mode is changed, the limitations of a traditional die configuration are broken, and precise forming and safe restoration of the controlled object are realized.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

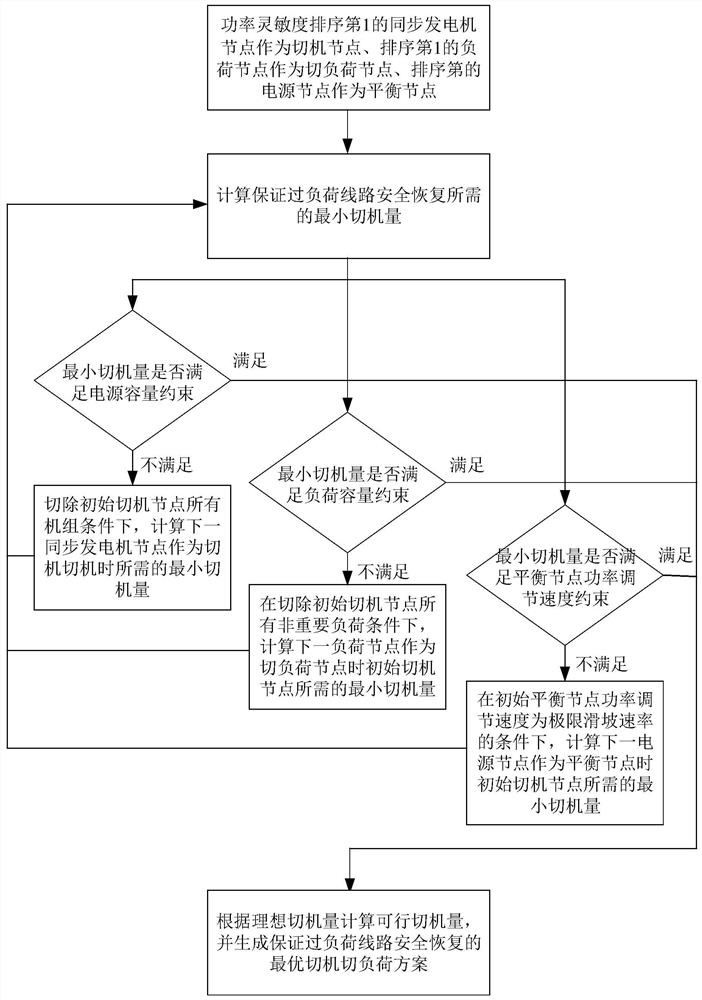

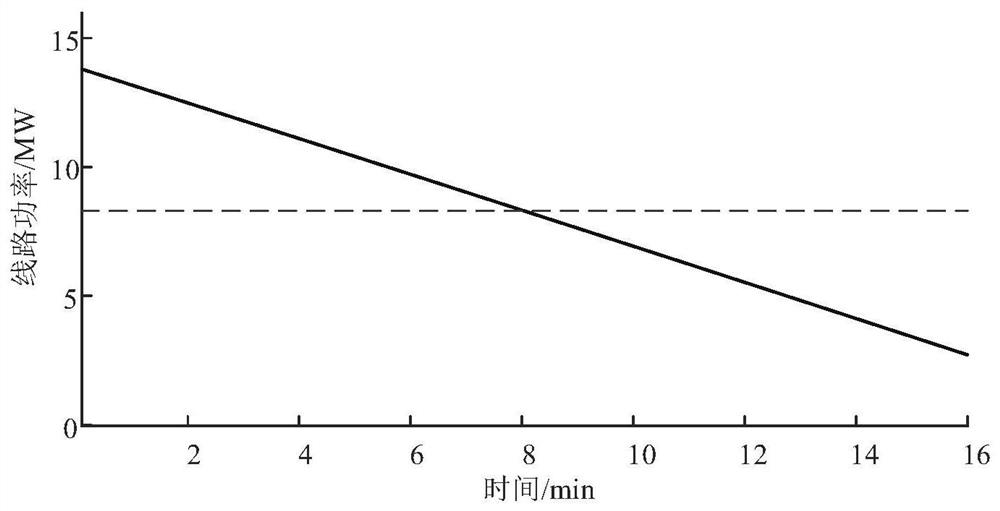

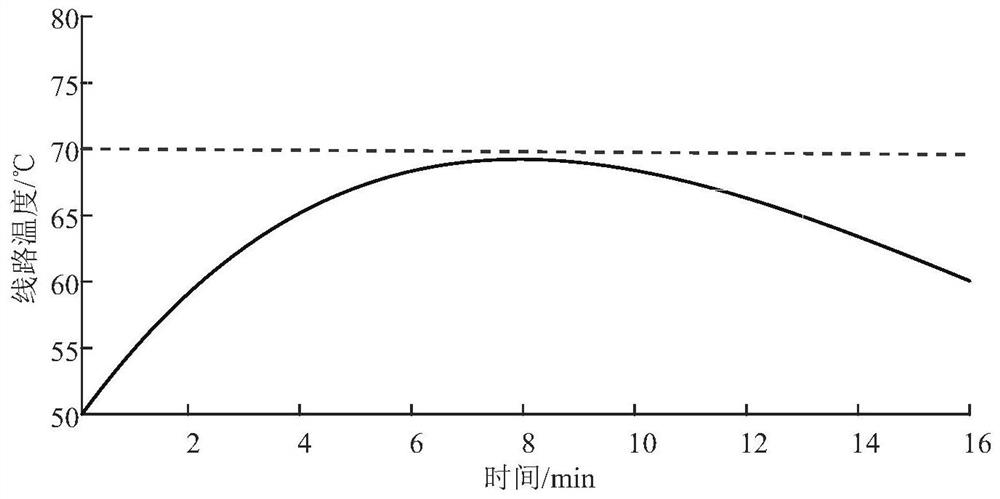

Electric power system cascading failure blocking method based on active minimum generator tripping

ActiveCN112688323AGuaranteed safe recoveryPower network operation systems integrationEmergency protective circuit arrangementsCascading failureLoad Shedding

The invention provides an electric power system cascading failure blocking method based on active minimum generator tripping, which is used for solving the problem of electric power system cascading failure caused by line overload in the prior art. A calculation method of the minimum generator tripping amount for blocking cascading failures is provided; meanwhile, by considering a power constraint, a load capacity constraint and a balance node adjustment speed constraint, a verification method for verifying the minimum generator tripping amount is provided; meanwhile, aiming at the condition that the minimum generator tripping amount does not meet the constraints, the invention provides a correction method of the minimum generator tripping amount. According to the method, the power control capability of the power supply in the power system can be utilized to the maximum extent, the power of the overload power transmission line is rapidly recovered, and the generator tripping and load shedding power is reduced as much as possible, so that cascading failures of the power system are effectively blocked, the blocking cost is reduced, and the power system stability is improved.

Owner:CHONGQING UNIV

Reinforcing method for crushed top plate of coal face

InactiveCN102877858BTo achieve the purpose of strengthening the broken roofImprove reinforcementUnderground chambersTunnel liningEngineeringSlurry

A reinforcing method for a crushed top plate of a coal face relates to the safety technical field of the coal face of a coal mine, can reinforce the crushed top plate through the combined action of a wire rope and slurry, forms an unique space grid reinforced structure, overcomes not only the defects of unobvious single grouting reinforcing effect and high cost, but also the defects of large labor intensity, long period and failure in fundamentally solving top leakage when the crushed top plate is treated by erecting a shed, and is obvious in crushed top plate reinforcing effect. Integrated with the advantages of grouting reinforcement, and matched with a specially excavated measure laneway, the method is free of time and space, and can pre-reinforce a composite thin crushed top plate before coal bed exploitation, and reinforce an area with the possibility of top leakage during coal bed exploitation, so as to ensure safe stopping of the coal face.

Owner:ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com