Parallel digging, mining and filling operation coal mining method for controlling overlaying strata fracture and surface subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

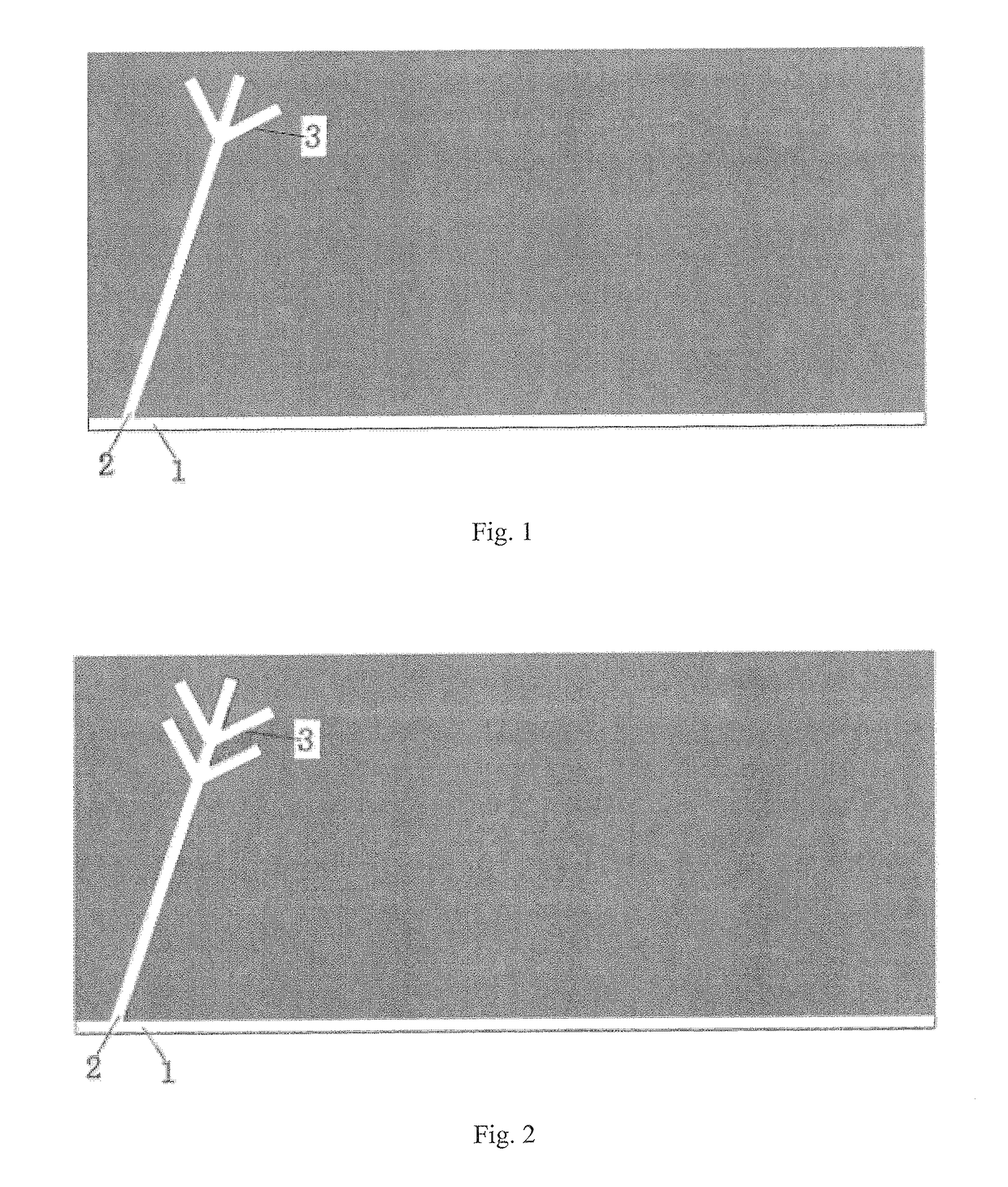

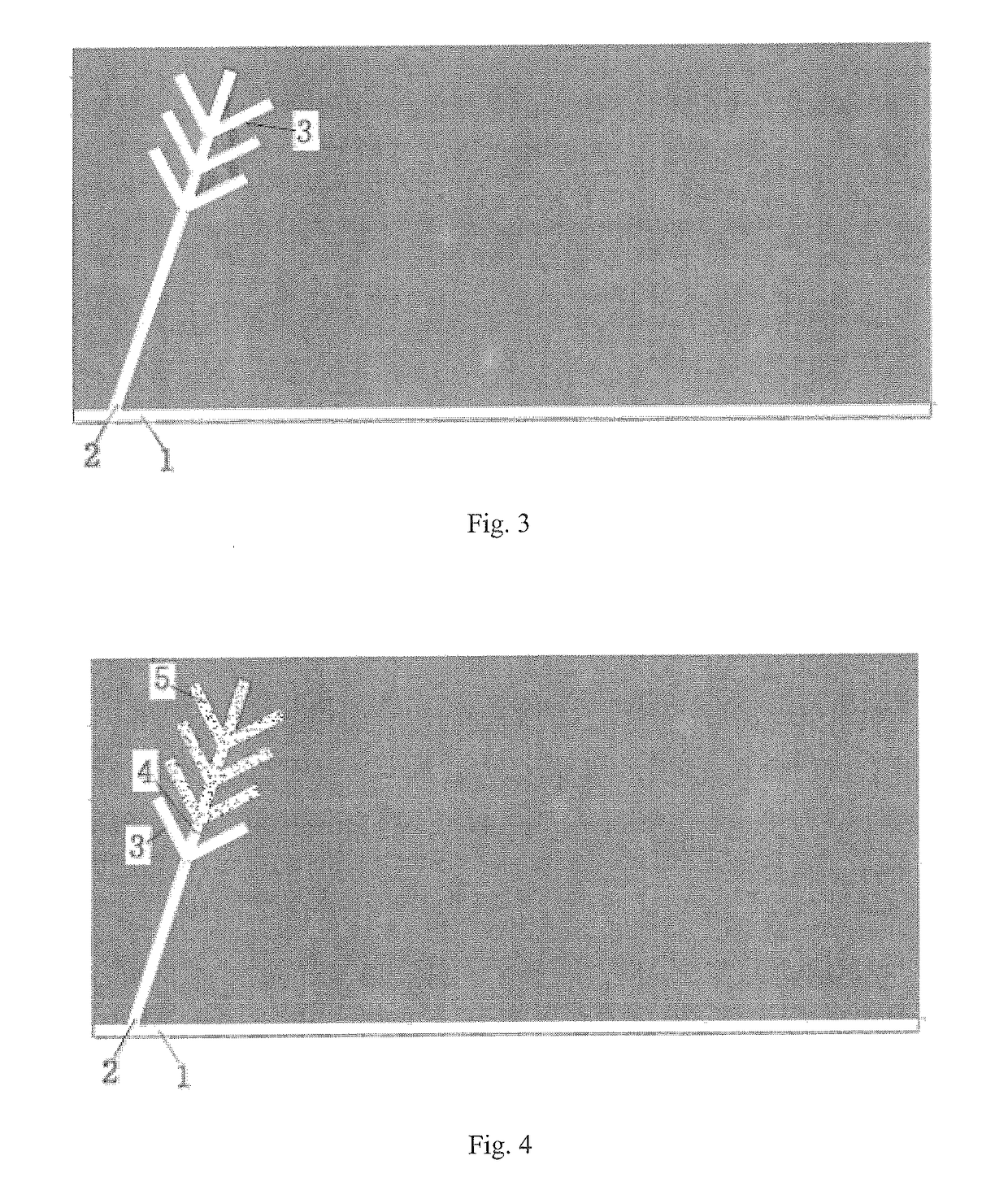

[0036]Hereunder the present invention will be further detailed in an embodiment, with reference to the accompanying drawings. The parallel digging, mining and filling operation coal mining method for controlling overlaying strata fracture and surface subsidence provided in the present invention includes the following steps:[0037]a. as shown in FIG. 1, a stope haulage roadway I 1 is arranged along the edge part of a stope, and a stope branch roadway I 2 is dug perpendicularly or obliquely to the stope haulage roadway I 1; or, a stope haulage roadway I 1 can be arranged in the middle of the stope directly, and a stope branch roadway I 2 is arrange at each side of the stope haulage roadway I 1.[0038]b. then, performing multiple two-winged adits mining in the coal mass along the stope branch roadway I 2 from inner side to outer side; the included angle α between the direction perpendicular to stope branch roadway I 2 and the two-winged adit 3 shall meet the requirement of turning of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com