Method for ensuring safe stoping of working face under old fire area of shallow-buried close-distance coal seam group

A short-distance, working face technology, applied in ground mining, underground mining, safety devices, etc., can solve problems such as excessive harmful gas and natural ignition in goafs, so as to ensure safe mining, prevent spontaneous ignition, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

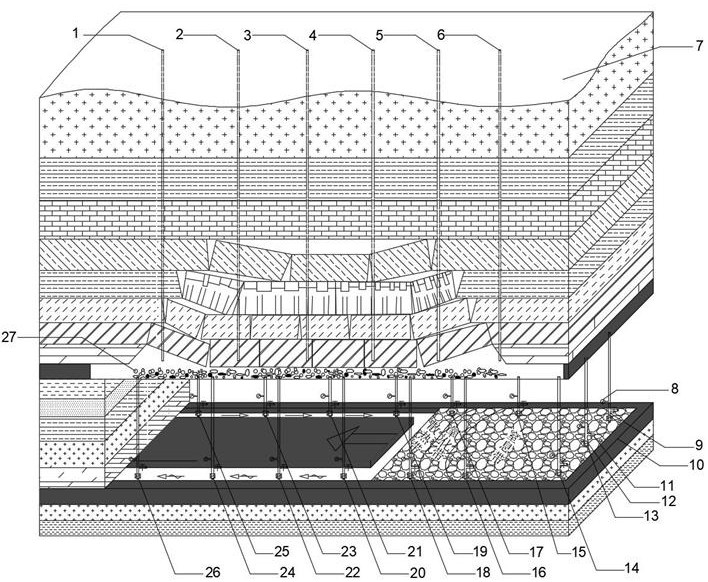

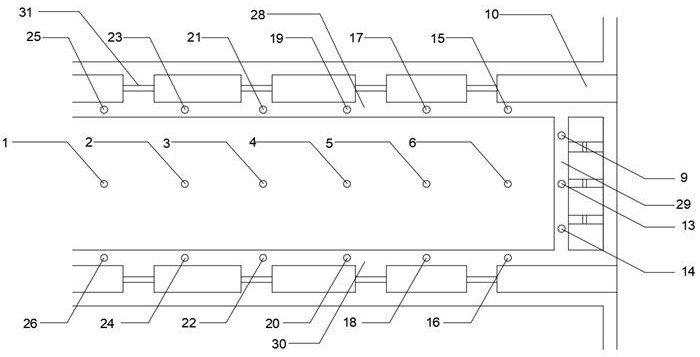

[0018] The implementation of a method for ensuring the safe recovery of the working face under the old fire area of shallow buried close-distance coal seam group will be further described in detail below in conjunction with the accompanying drawings.

[0019] A method for ensuring safe recovery of a working face under an old fire area of a shallow buried coal seam group comprising the following steps.

[0020] S100~ Excavate the coal recovery working face under the shallow buried coal seam group. After the working face layout is completed, make observation-vent holes in the old fire area in the air inlet trough 28, return air trough 30 and cut hole 29, and insert Thermocouples measure the temperature at different positions in the old fire area, take gas samples through the gas sampling valve 11 to analyze the gas composition in different positions in the fire area, and check whether there is still coal spontaneous combustion in the old fire area through the observation-vent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com