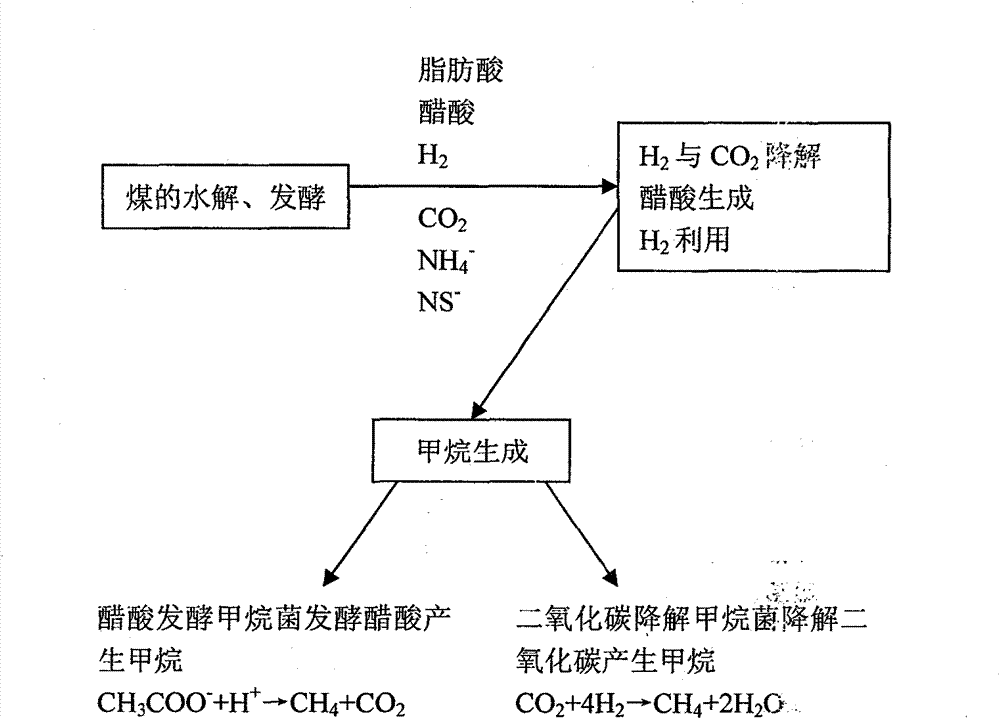

Method for making natural gas by underground coal bed microorganism

A natural gas and microorganism technology, applied in coal gasification, underground mining, construction, etc., can solve the problems of non-reusable coal resources, suboptimal energy utilization rate, low coal gasification conversion rate, etc., and improve the utilization of coal resources. The effect of high degree of conversion, high conversion rate, and improved drainage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described below through an embodiment according to the detailed process.

[0025] Step 1: Select the pre-mining area of a certain coalfield as the area where coal-to-gas is implemented, and open an isolation zone between the areas to isolate it from other areas, and circulate and inject air into this area. The amount of air injected should ensure that the isolation zone The oxygen reduction potential of the coal surface is higher than 500mV.

[0026] The second step: analyze the coal quality, ground temperature, hydrological conditions, oxygen content, etc. of the coal seam in the first step gasification area, and obtain the coal seam environmental characteristic data.

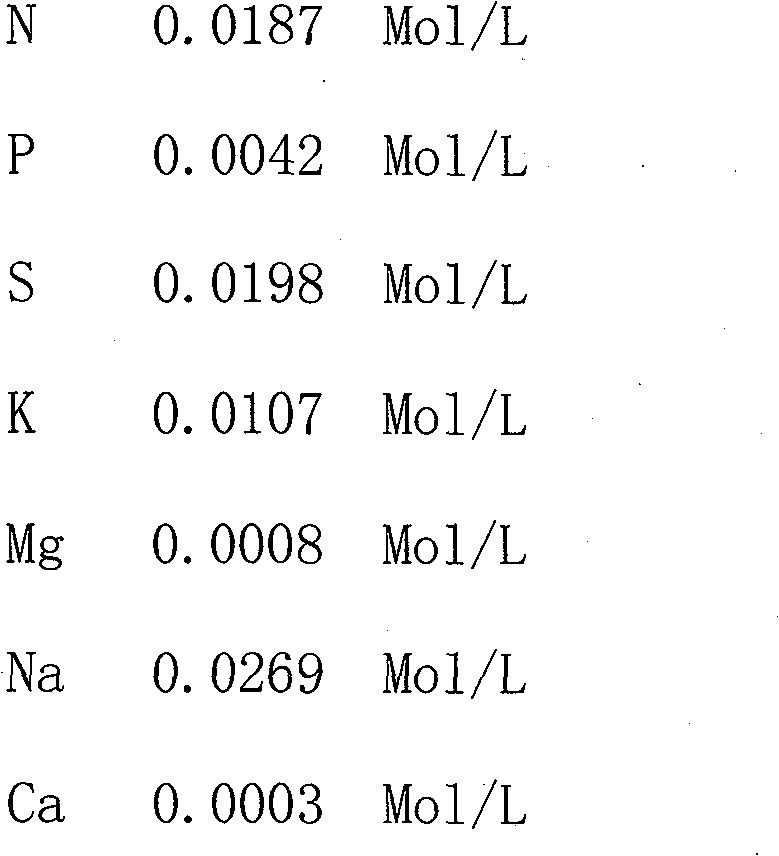

[0027] Step 3: Prepare the culture medium. The composition of each element in the conventional culture medium is shown in the table below.

[0028] element ConcentrationMol / L N 0.0187 P 0.0042 S 0.0198 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com