Leakage-proof stope face roof

A technology for mining working faces and roofs, which is applied to support the roof beams of mine roofs, mining equipment, earthwork drilling and mining, etc. It can solve problems such as potential safety hazards and poor stability of coal and rock mass, so as to ensure safe mining and improve overall stability Sexuality, the effect of increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

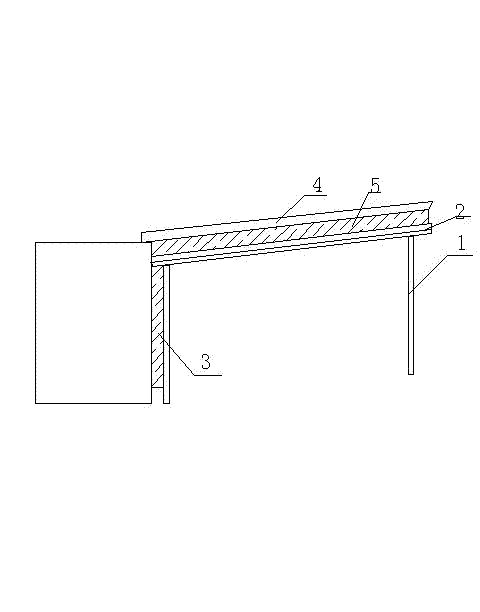

[0009] The leak-proof roof of the mining face is composed of pillars 1 arranged at intervals and beams 2 erected on the pillars 1. The bottom of the pillars 1 is fixed on the roadway floor, and the beams 2 are fixed on the top of the pillars 1. Filling piles 3 are filled between the side facing the side wall of the roadway and the pillar 1, and the feature is that: the upper side of the beam 2 faces the roof 4 of the roadway, and the filling pile 3 is filled between the beam 2 and the roof 4 Object 5.

[0010] The present invention also designs a layer of marisan between the filler 5 and the top plate 4 .

[0011] The present invention also designs that the beam 2 is a steel beam or a wooden beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com