Reinforcing method for crushed top plate of coal face

A technology for coal mining face and broken roof, applied in mining equipment, earthwork drilling, wellbore lining, etc., can solve the problems of low efficiency, poor safety, long construction period and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This example takes the large mining height working face of a certain mine as the specific research object. The coal mining face has experienced four large roof leakage accidents during the mining period, which seriously affected the safe production of the working face. , Grout injection, chemical slurry injection and other means, but the effect is not obvious, and there will still be roof leakage accidents afterwards.

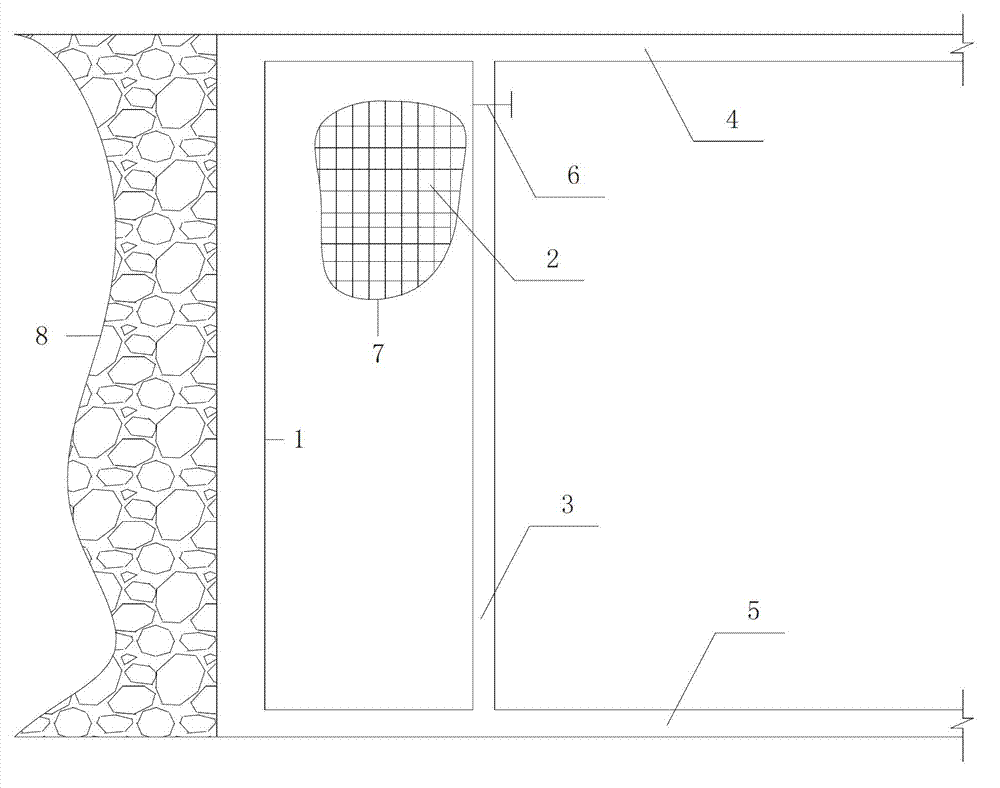

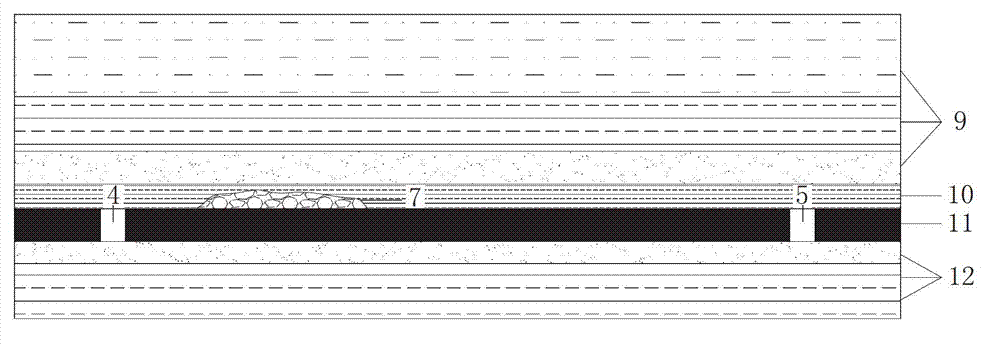

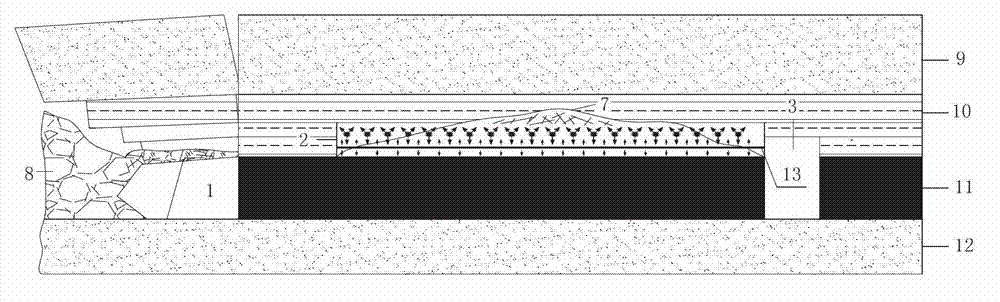

[0038] The drain top area is mainly concentrated on the top of the working surface, such as figure 1 As shown, the geological conditions of the coal mining face 1 are complicated, such as figure 2 , image 3 and Figure 4 As shown, the old roof is 9, the composite thin-layer broken direct roof is 10, the coal seam is 11, and the coal seam floor is 12. Three seismic surveys showed that it was an abnormal area of the coal seam, and the roof was broken. At the same time, the mining height of coal mining face 1 was relatively high, which intensified th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com