Method for determining hard roof working face deep hole pre-cracking forced roof caving parameter

A technology with a hard roof and a determination method, which is applied in ground mining, earth-moving drilling, data processing applications, etc., can solve the problems of difficulty in revealing the breaking mechanism of the basic roof stratum, and difficulty in controlling the effect of forced caving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

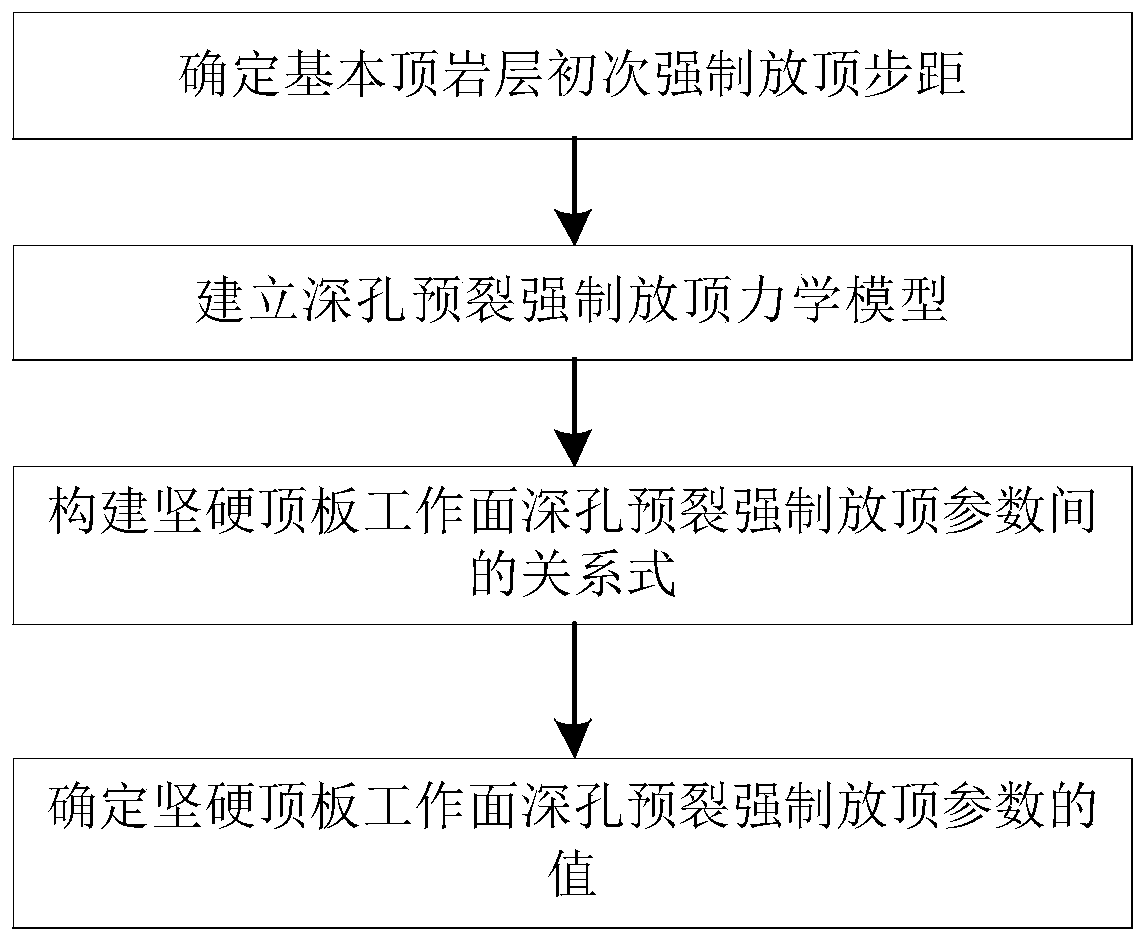

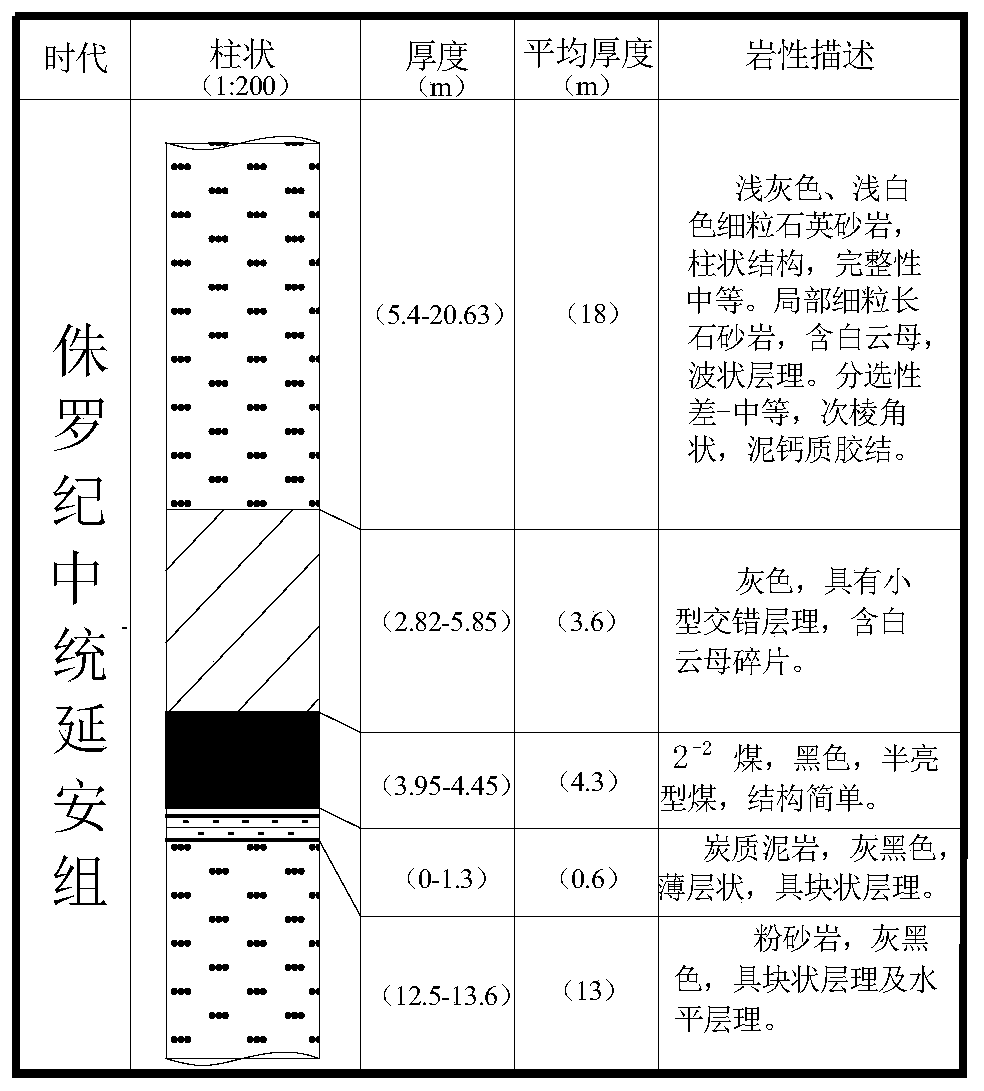

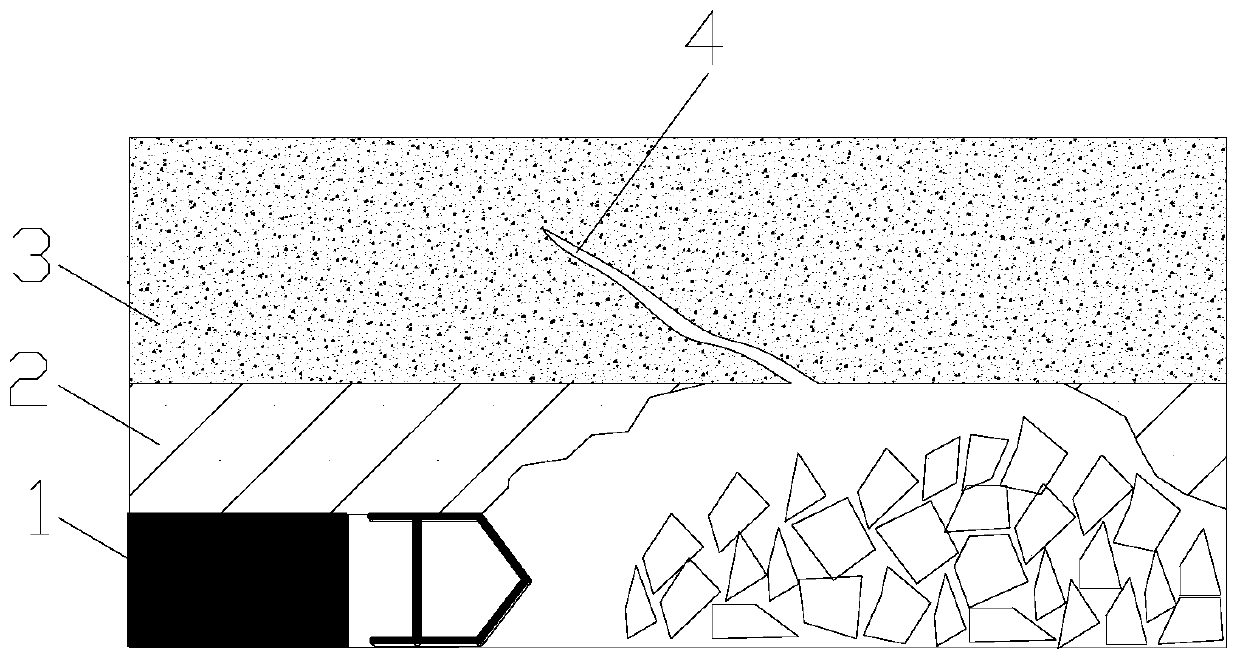

[0054] In this embodiment, as figure 1 As shown, a method for determining the parameters of deep hole pre-splitting forced roof caving in a hard roof working face of the present invention, said hard roof working face includes a hard roof working face coal seam 1, a direct roof rock layer 2 and a hard roof working face distributed sequentially from the bottom to the top Basic top rock layer 3, the method for determining the parameters of the hard roof working face deep hole pre-splitting forced caving comprises the following steps:

[0055] Step 1. Determine the initial forced topping step distance L of the basic top rock layer 3 0 ;

[0056] In the present embodiment, the basic top rock layer 3 described in step 1 is forced to put the top step distance L for the first time 0 The step distance is smaller than the basic top initial pressure step and greater than the basic top cycle pressure step distance.

[0057] During specific implementation, if the initial forced topping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com