Room-and-pillar mining method for mining gentle dip thin ore body

A mining method and thin ore body technology, applied in the field of room-and-pillar mining, can solve problems such as large differences in the stability of the roof of the ore body, affecting mining work efficiency, and obstructed equipment operation, so as to facilitate mechanized mining and realize mechanized mining. The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

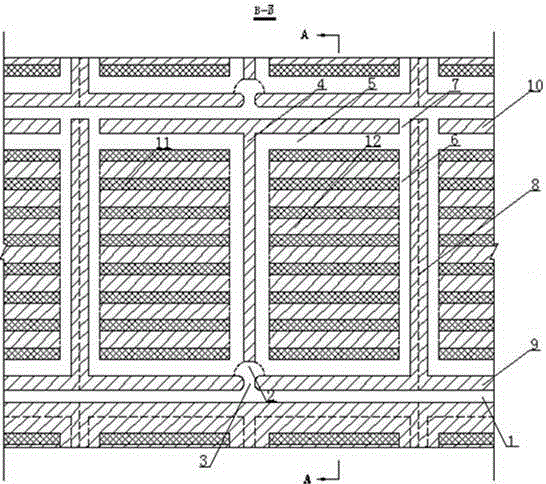

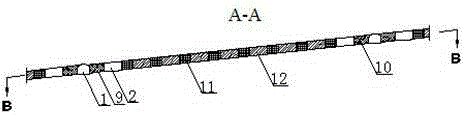

[0035] refer to figure 1 , 2 , 3, 4, the present embodiment carries out mining for the ore body that ore body roof is unstable, comprises the following steps:

[0036] (1) Arrange the ore block stope along the ore body. The length of the ore block is 120m, the width is 100m, and the height is the height of the ore body layer (generally 2-3m). A 5m wide bottom column 9 and top are reserved in the ore block. Column 10 and inter-column 8 form a mining room, and the mining room and the mining room are separated by a segmented roadway 1; a 4m-wide return air outlet 7 is reserved at both ends of the top column 10, and a 4m-wide mine is reserved in the middle of the bottom column 9. Entrance 3 of the room, a separation pillar 4 with a width of 4m in the direction of the vertical ore body is reserved in the middle of the mine room, and the separation pillar 4 divides the mine room into two small mine rooms;

[0037] (2) Construction of 4m wide cutting uphill 6 and cutting level road...

Embodiment 2

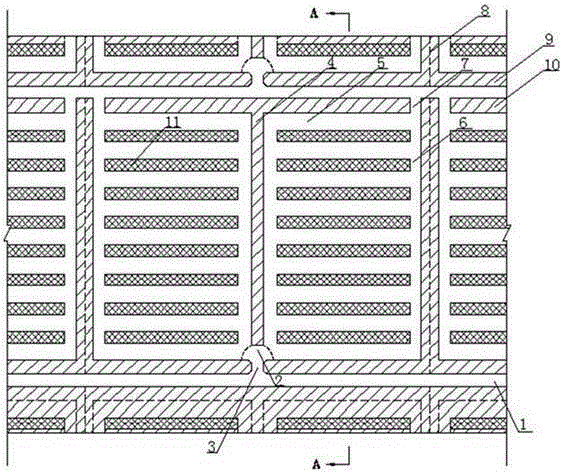

[0041] refer to figure 1 , 2 , 5, 6, the present embodiment carries out mining for the ore body that the ore body roof is generally firm, comprises the following steps:

[0042] (1) Arrange the ore block stope along the ore body. The length of the ore block is 120m, the width is 100m, and the height is the height of the ore body layer (generally 2-3m). A 5m wide bottom column 9 and top are reserved in the ore block. Column 10 and inter-column 8 form a mining room, and the mining room and the mining room are separated by a segmented roadway 1; a 4m-wide return air outlet 7 is reserved at both ends of the top column 10, and a 4m-wide mine is reserved in the middle of the bottom column 9. Entrance 3 of the room, a separation pillar 4 with a width of 4m in the direction of the vertical ore body is reserved in the middle of the mine room, and the separation pillar 4 divides the mine room into two small mine rooms;

[0043] (2) Construction of 4m wide cutting uphill 6 and cutting ...

Embodiment 3

[0047] refer to figure 1 , 2 , 7, 8, 9, the present embodiment is mined for the ore body that the ore body roof is firm, comprises the following steps:

[0048] (1) Arrange the ore block stope along the ore body. The length of the ore block is 120m, the width is 100m, and the height is the height of the ore body layer (generally 2-3m). A 6m wide bottom column 9 and top are reserved in the ore block. Column 10 and inter-column 8 form a mining room, and the mining room and the mining room are separated by a segmented roadway 1; a 4m-wide return air outlet 7 is reserved at both ends of the top column 10, and a 4m-wide mine is reserved in the middle of the bottom column 9. Entrance 3 of the room, a separation pillar 4 with a width of 4m in the direction of the vertical ore body is reserved in the middle of the mine room, and the separation pillar 4 divides the mine room into two small mine rooms;

[0049] (2) Construction of 4m wide cutting uphill 6 and cutting level roadway 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com