Powder metallurgy finished product drying equipment

A technology of drying equipment and powder metallurgy, which is applied in drying, drying machines, lighting and heating equipment, etc., which can solve the problems of uncontrollable drying temperature and imperfect heat dissipation system, so as to reduce the temperature and prevent shock damage , the effect of preventing burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

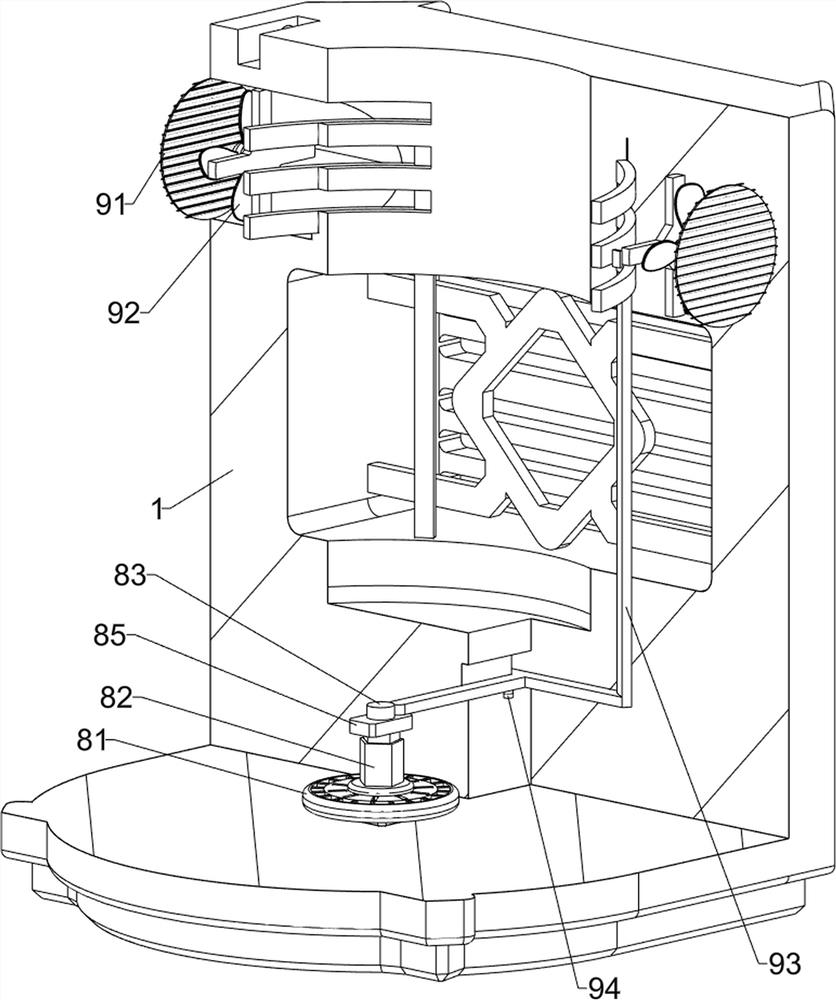

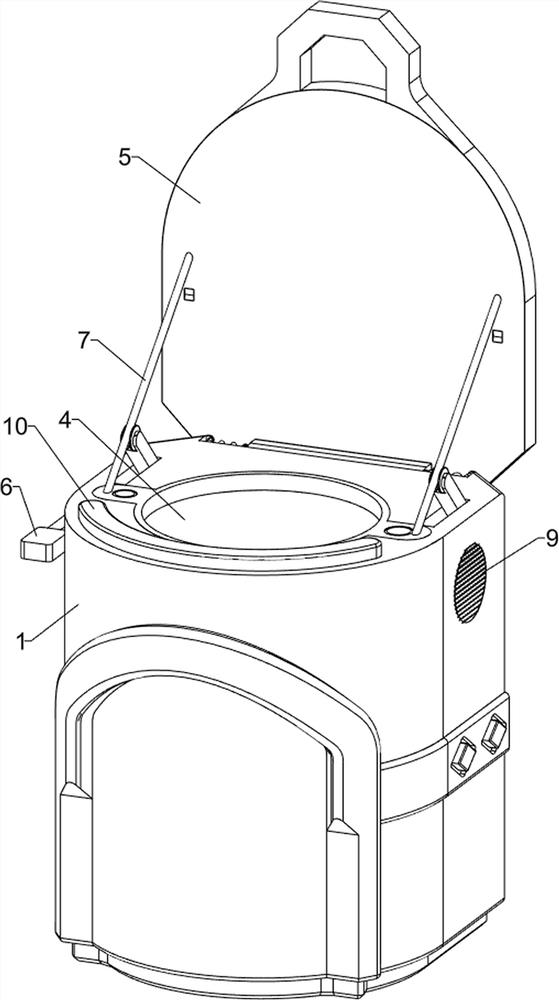

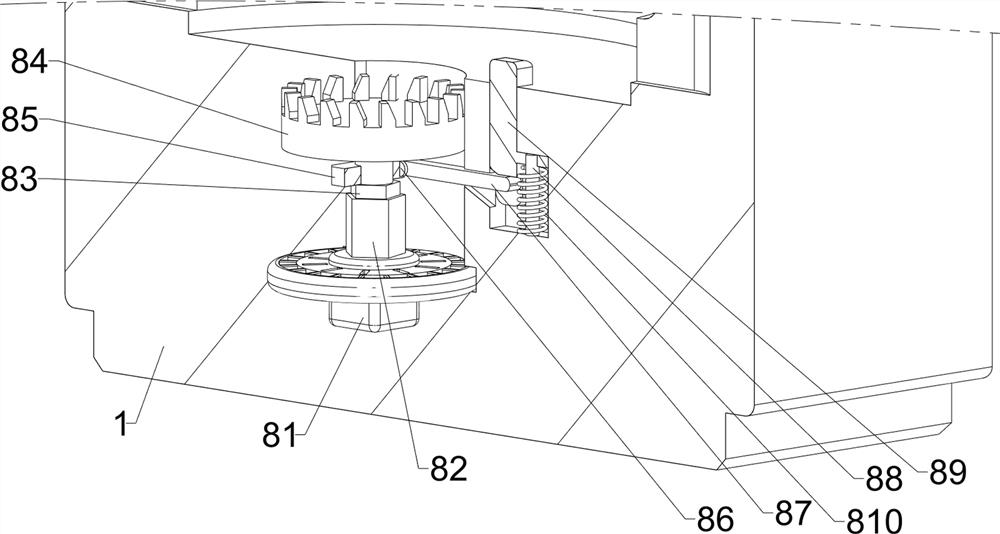

[0029] A drying equipment for powder metallurgy products, such as Figure 1-Figure 5 As shown, it includes a casing 1, a first fan blade 2, a heating pipe 3, a placement plate 4, a cover assembly 5 and a clamping assembly 6, and the rear side of the casing 1 is provided with the first fan blade 2 in a symmetrical rotation type, and the casing 1 There are vents on the left and right sides, a heating pipe 3 on the inner and rear side of the shell 1, a sliding plate 4 on the shell 1, a cover component 5 on the shell 1, and a clamping component 6 on the shell 1. The clamping component 6 cooperates with the cover component 5 .

[0030] First, people squeeze the clamping component 6 downward to unlock the clamping component 6 and the cover component 5, open the cover component 5, place the metallurgical products that need to be dried on the placement plate 4, and close the cover component 5 , the first fan blade 2 draws in the wind and converts the natural wind into hot air through...

Embodiment 2

[0036] On the basis of Example 1, such as Figure 6-Figure 9 As shown, it also includes a riser assembly 7, and the riser assembly 7 includes a second guide rod 71, a support plate 72, a second spring 73, a pull cord 74, a second connecting rod 75, a roller 76 and a spring 77, inside the housing 1 A second guide rod 71 is symmetrically arranged on the left and right, and a support plate 72 is slidably provided between the second guide rods 71. The placement plate 4 is connected to the support plate 72 in a rotational manner, and the support plate 72 is symmetrically connected to the shell 1 with a second guide rod. Two springs 73, the second spring 73 are respectively sleeved on the second guide rod 71, a stay rope 74 is symmetrically connected between the support plate 72 and the cover plate 52, and the left and right symmetrical rotation type is provided with the second connecting rod 75 on the shell 1, the second Both connecting rods 75 are provided with rollers 76 in a rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com