Continuous mining method in vertical direction and application thereof to full ore body continuous mining

A vertical direction and mining method technology, applied in ground mining, mining equipment, earth square drilling and mining, etc., can solve problems that affect the balance of mine production, difficult to recover horizontal ore pillars, and easy to be damaged by geological activities, so as to improve comprehensive production ability, reduce the loss of ore volume, and shorten the recovery period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

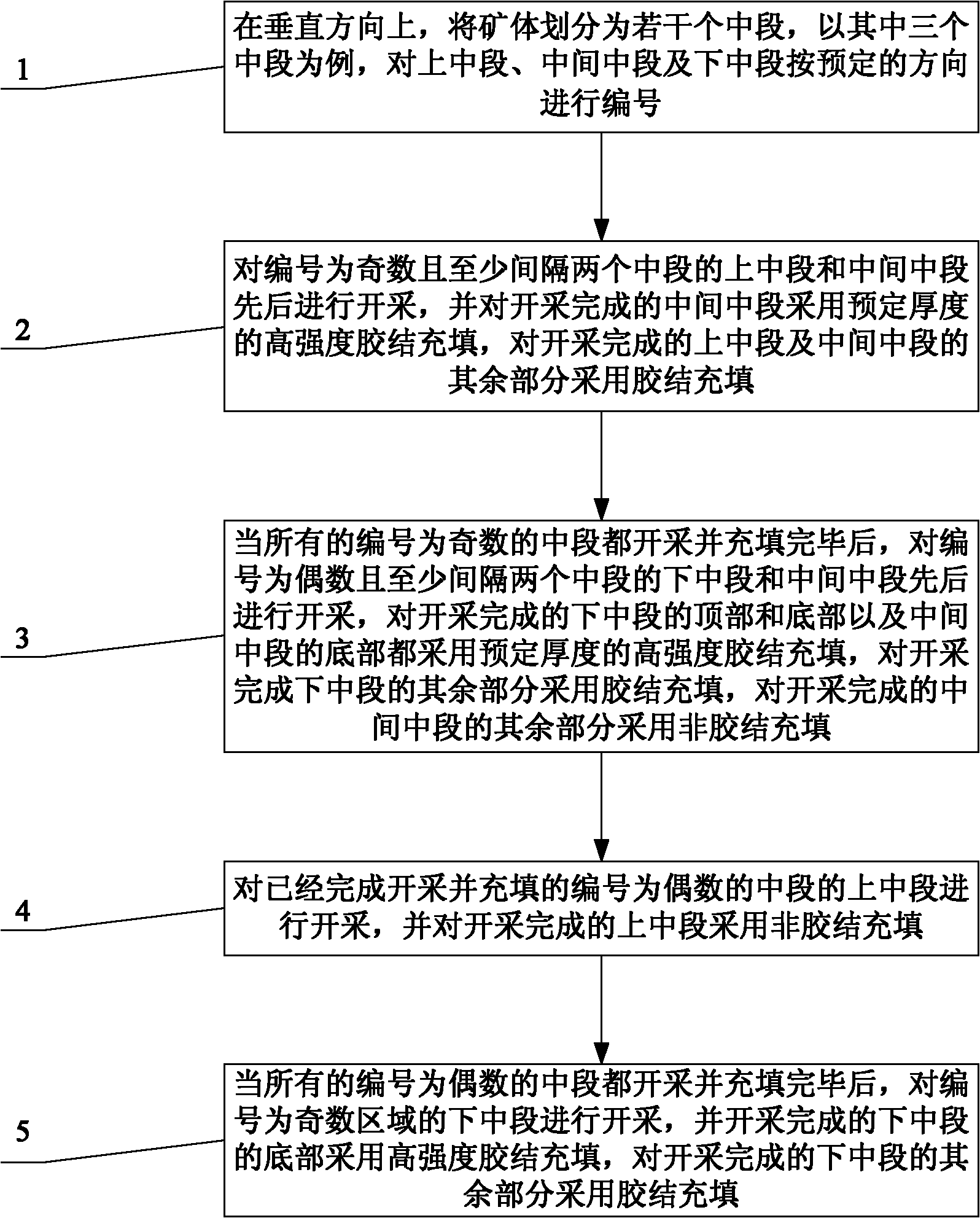

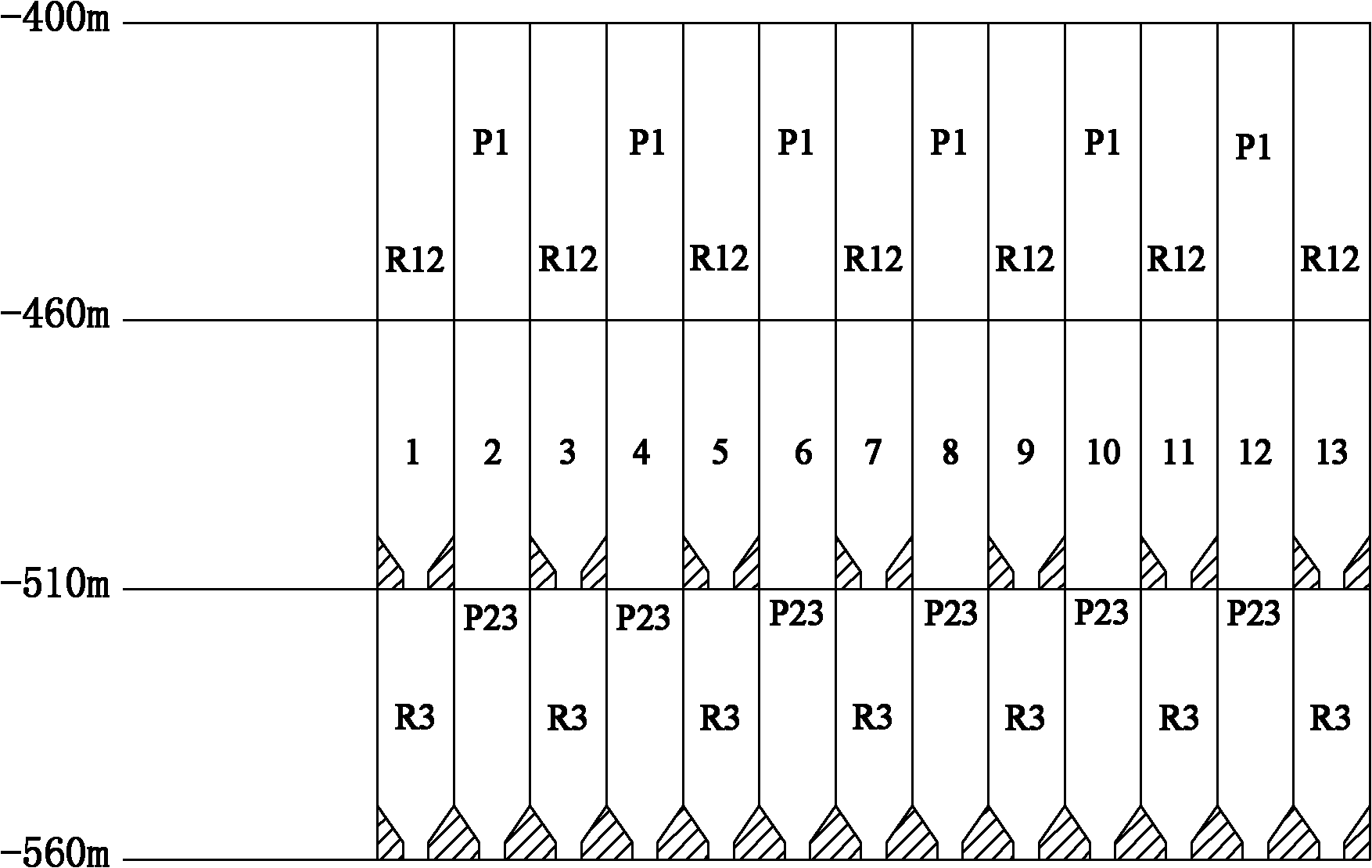

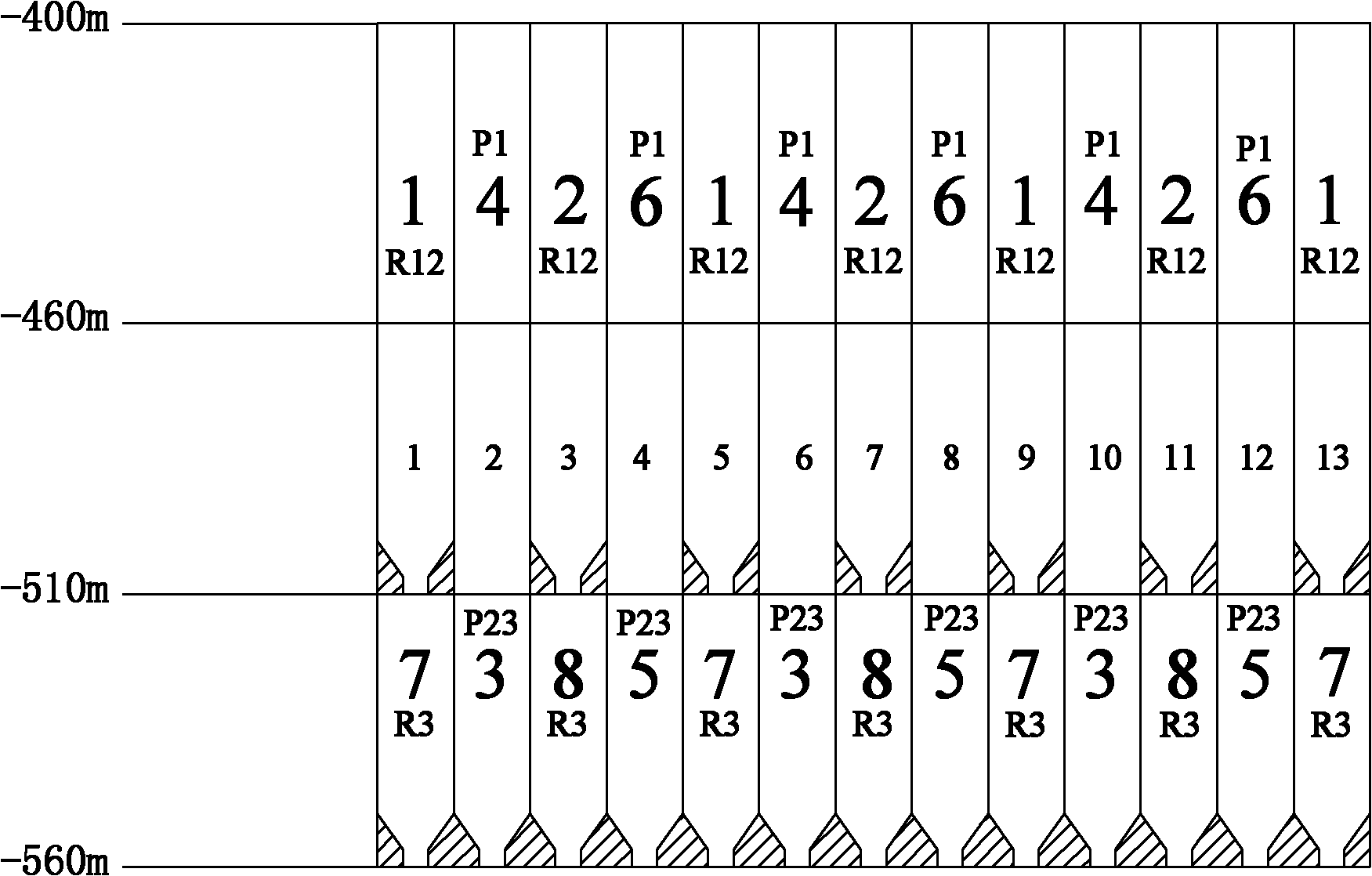

[0022] This specific embodiment provides a vertical continuous mining method, including dividing the ore body into several middle sections in the vertical direction, taking the three middle sections as an example, numbering the upper middle section, the middle middle section and the lower middle section according to a predetermined direction; The upper middle section and the middle middle section with an odd number and at least two middle sections are mined successively, and the middle and middle sections that have been mined are filled with high-strength cement with a predetermined thickness, and the remaining parts of the upper middle section and the middle middle section that have been mined are cemented. Filling; when all the odd-numbered middle sections have been mined and filled, the lower middle section and the middle middle section with an even number and at least two middle sections are mined successively, and the top and bottom of the lower middle section and the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com