House pillar type coal mining method

A coal mining method and room-and-pillar technology, which is applied in the coal mining field of underground coal mines to fully recover scrap coal, can solve the problems of large coal room space, low resource recovery rate, coal spontaneous combustion, etc., and achieve improved ventilation conditions , The ability to adapt to the roof is strengthened, and the effect of eliminating the breeze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

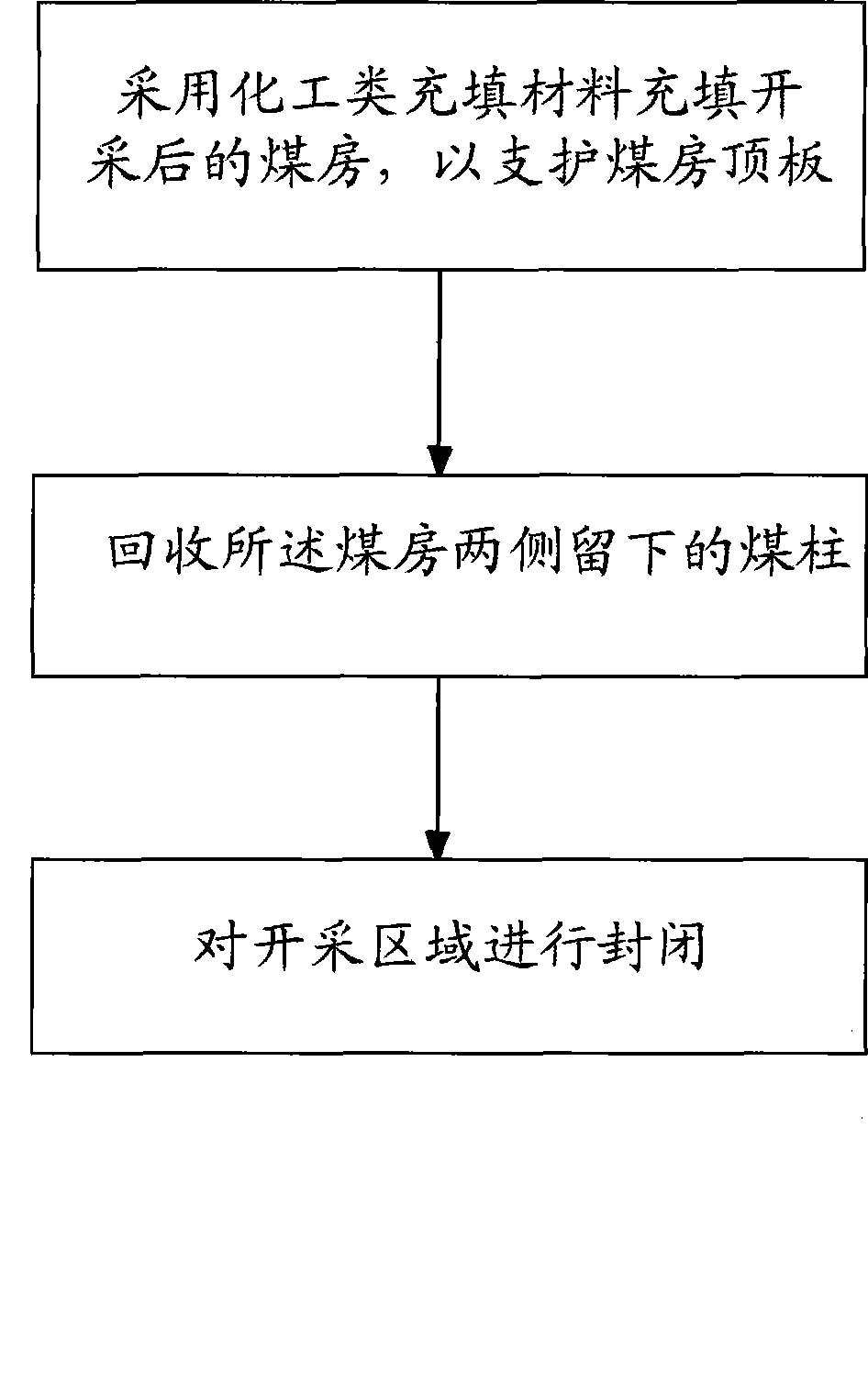

Method used

Image

Examples

Embodiment Construction

[0017] The room-and-pillar coal mining method provided by the present invention will be further described in detail below, but the present invention is not limited thereto.

[0018] Coal room filling material

[0019] In the method provided by the present invention, the foam material that meets the strength requirements can be selected as the coal room filling material to form an artificial "rock mass" to support the roof of the coal room, so as to safely recover the coal pillars left on both sides of the raw coal room . The solidification strength after filling of the foaming material should ensure that the strength of the chemical material used after foaming is greater than the unidirectional compressive strength of the coal seam to be mined. Taking Shendong Coalfield as an example, the average unidirectional compressive strength of the coal seam is 15-20Mpa. When the method provided by the present invention is used for mining, the solidification strength of the selected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com