Room-and-pillar mining method for medium-thickness gently inclined ore bodies with waste rock interlayer

A kind of gently inclined, mining method technology, applied in surface mining, underground mining, special mining and other directions, can solve the waste of resources, manpower and material resources, reduce the value of the mined ore, and the ore grade of the mined ore cannot reach the selected grade. , to achieve the effect of large production capacity, low poverty loss and high resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

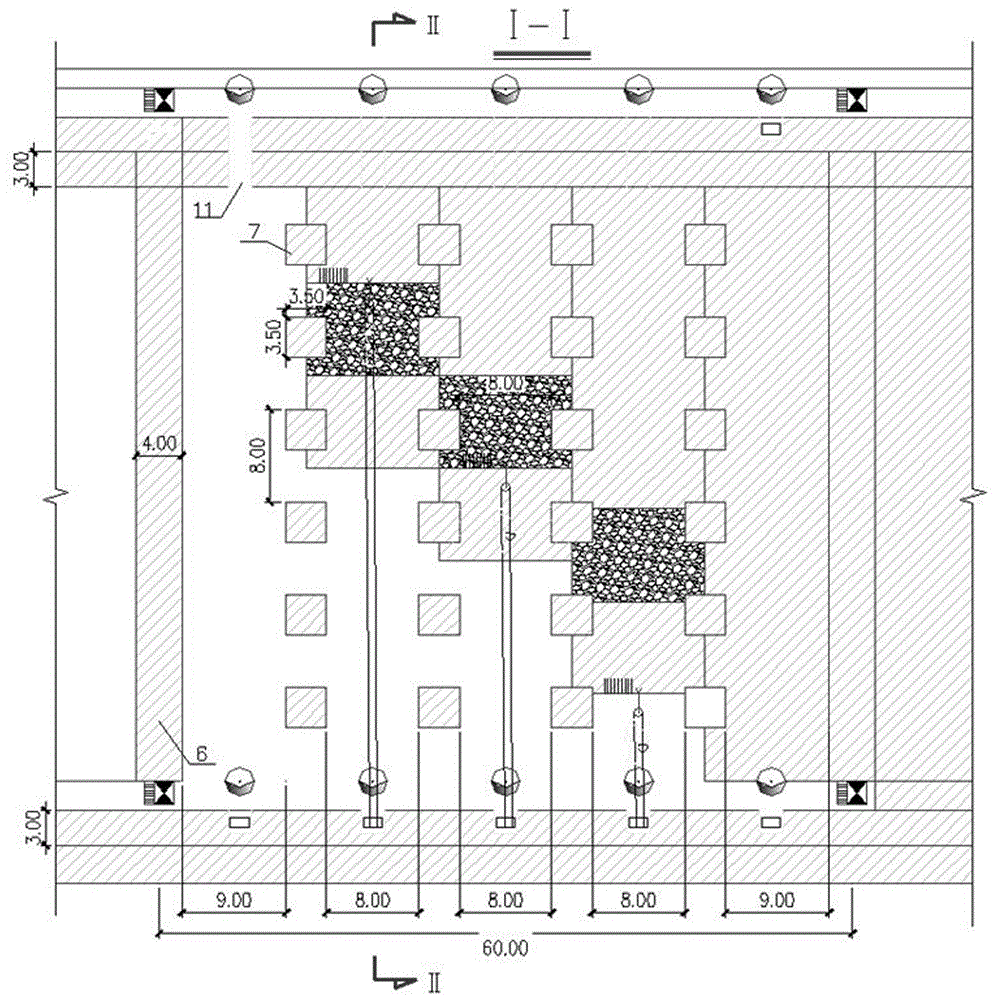

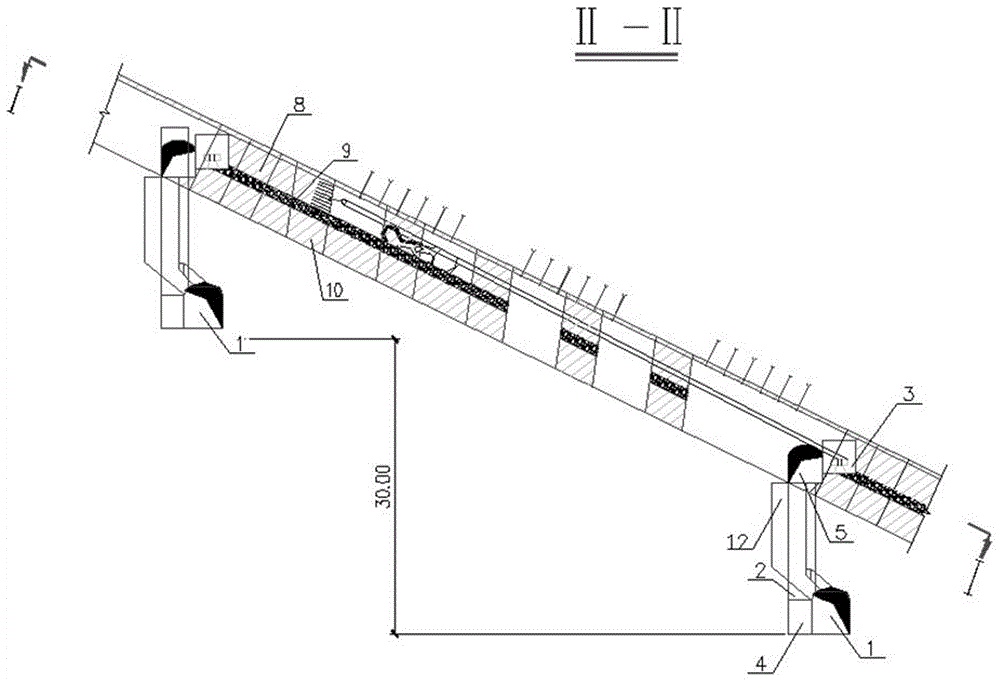

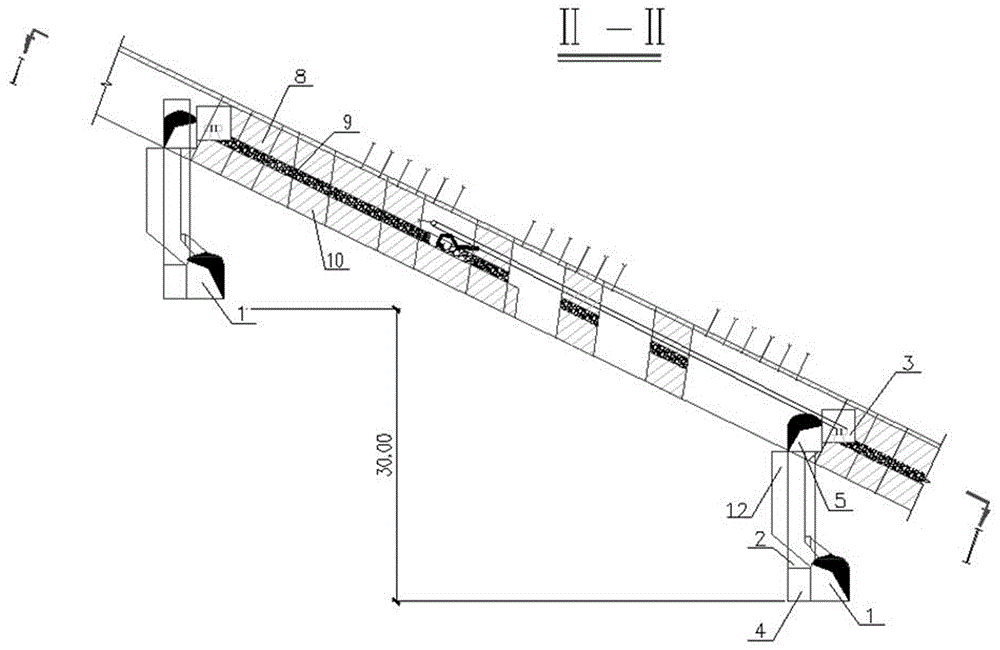

[0034] Example 1: Shallow-hole layered room-and-pillar mining method for rock bolt roof protection in a mine in Guizhou.

[0035] The No. 2 ore body mined in the first phase of a certain mine has an average inclination angle of 26.40°. The stability of the surrounding rock of the roof and the immediate roof of the mine is generally poor, and the stability of the surrounding rock of the floor and the immediate floor is good. body, and the waste rock interlayer needs to be removed from the refractory ore body. The Mn geological grade of the lean ore in the upper layer of No. 2 ore body is 13.21%, with an average thickness of 2.77m; the Mn geological grade of the lower rich ore raw ore is 17.04%, with an average thickness of 2.00m; the Mn geological grade of the interlayer waste rock is 6.25%, with an average thickness of 0.89m. Combined with the actual physical characteristics and grades of the No. 2 ore body ore and interlayer waste rock in a certain mine, under the premise tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com