Baking apparatus

A technology for baking equipment and equipment, which is applied to heat storage equipment, lighting and heating equipment, energy storage, etc., can solve the problems of affecting smoke quality, large environmental pollution, and mixing tobacco leaves with soot, so as to reduce baking costs and protect the environment. , the effect of improving the baking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

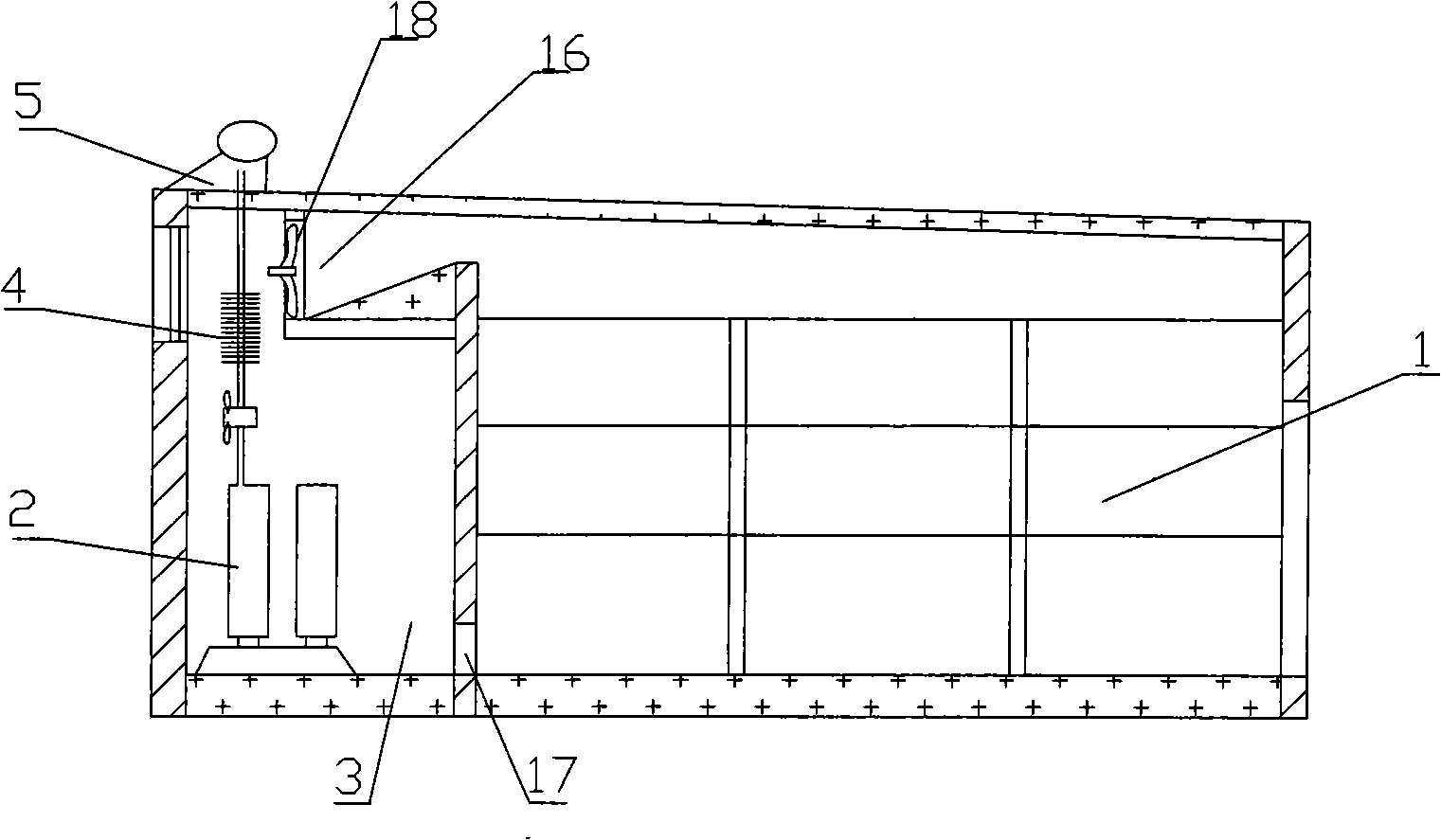

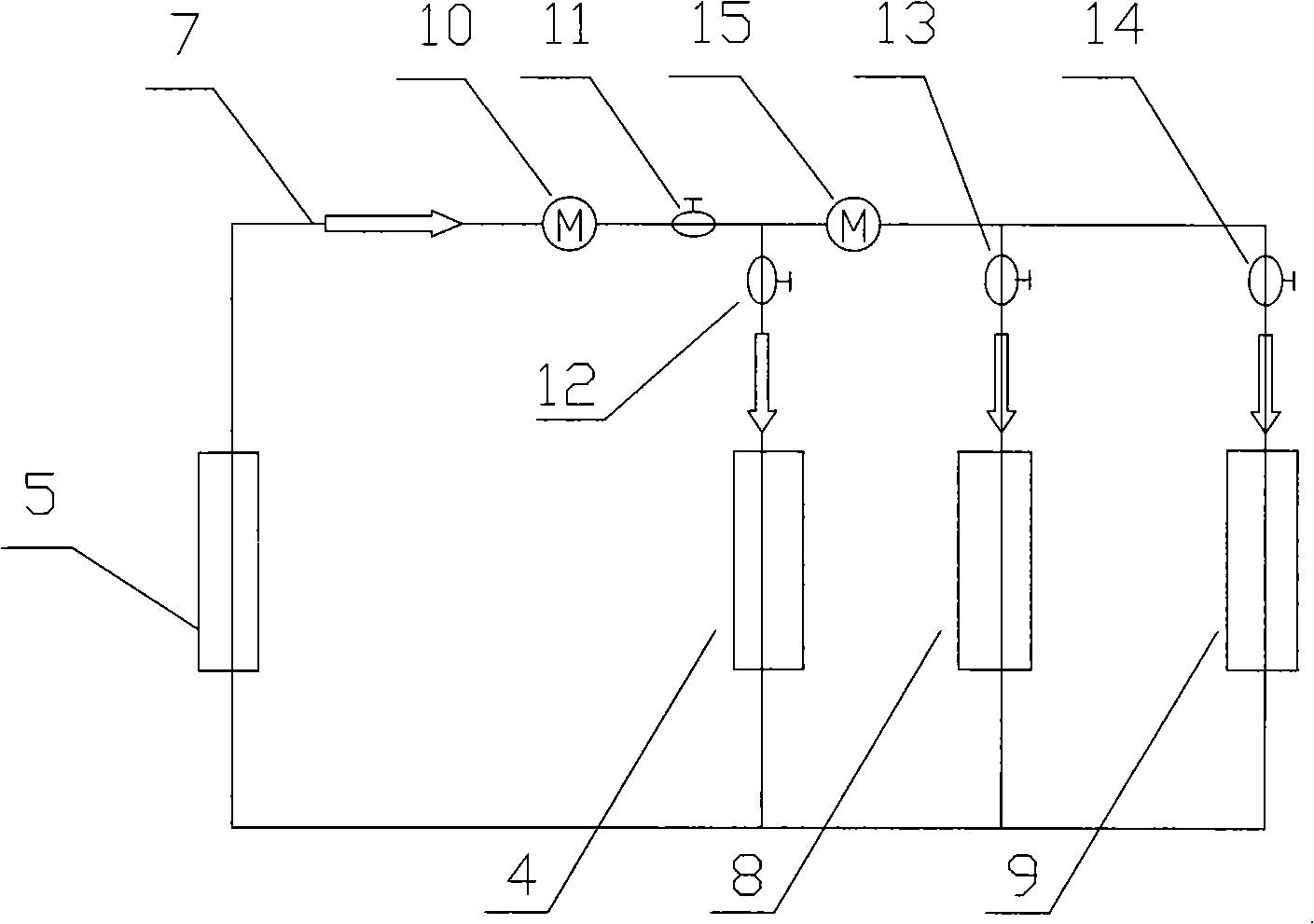

[0008] The baking equipment of the present invention includes a baking chamber 1 that can hold baked objects and a baking heating equipment 2. The baking heating equipment 2 is a solar heating equipment, and the solar heating equipment includes a The fluid heat exchanger 4 inside the heating chamber 3 on the side of the chamber 1 and the solar fluid heat collecting device 5 connected with the fluid heat exchanger outside the heating chamber, and a heat cycle communicating with each other is provided between the baking chamber 1 and the heating chamber 3 aisle.

[0009] The baking heating equipment 2 is also provided with a fluid heat storage device 8 and a fluid auxiliary heating device 9 connected in parallel with the solar fluid heat collecting device 5 and the heat flow pipeline 7 of the fluid heat exchanger 4. The heat flow pipeline is provided with a first Control the pump 10 and the first heat flow opening and closing valve 11. The heat flow branches where the fluid heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com