Low-moisture lithium-ion battery diaphragm

A lithium-ion battery and diaphragm technology, which is applied to battery components, circuits, electrical components, etc., can solve the changes in the electrochemical characteristics of lithium-ion batteries, affect the consistency of internal resistance of lithium-ion batteries, excessive moisture in coating films, etc. problem, achieve the effect of saving baking cost, improving battery performance, and reducing moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

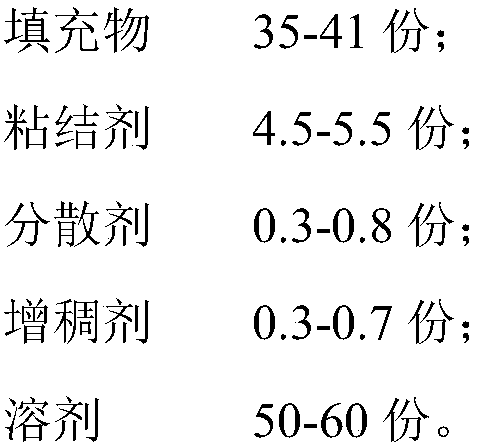

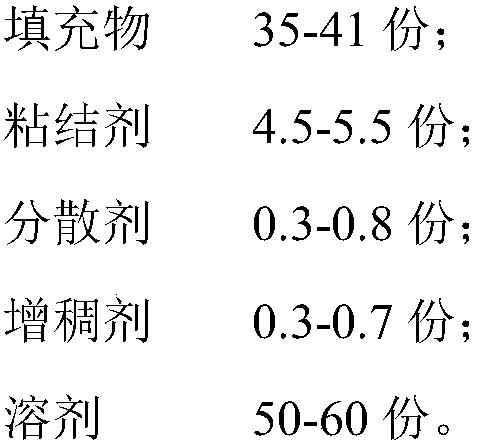

Method used

Image

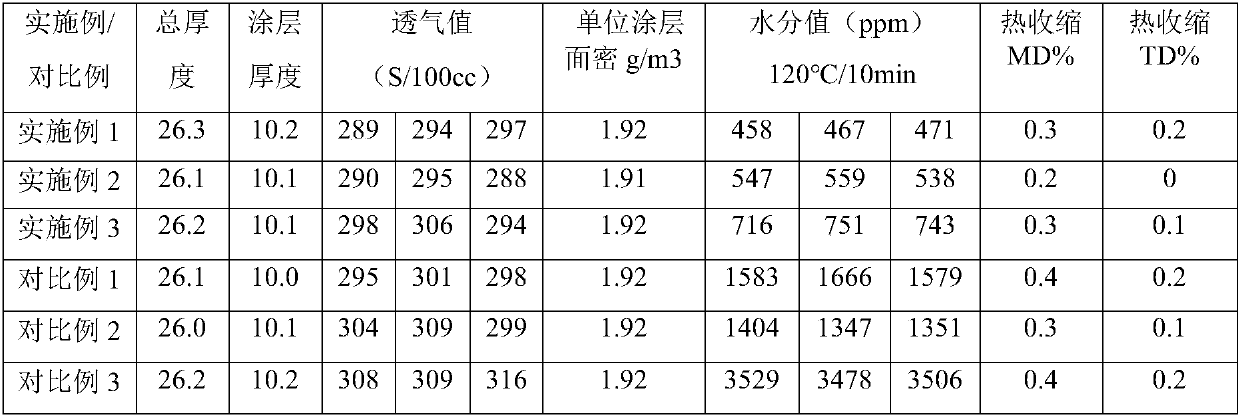

Examples

Embodiment 1

[0033]a) Weigh 0.15Kg of dispersant (model: SN5040, supplier: Guangzhou Huixiang Chemical Co., Ltd.) and add it to 15Kg of pure water and stir until it is completely dispersed and uniform to form a dispersion. Take 0.12Kg of thickener (model: CMC1220 (supplier: Suzhou Fosai New Material Co., Ltd.) is added to the dispersion, and after stirring evenly, 10kg of nano-alumina powder (filler D50 = 0.95μm) is added to the solution to make slurry A, and the slurry A carries out high-speed dispersion, after cooling to normal temperature, (take by weighing 1.33kg) low water-absorbing molecular weight is 200,000-500,000, solid content is 44-46% aqueous acrylic resin aqueous solution (model: BM-930B, supplier: Japan ZEON Co., Ltd.) into the dispersed slurry, fully stirred, after stirring evenly, the low-moisture slurry is prepared in this way;

[0034] b) Take a base film with a thickness of 16 μm, and apply the low-moisture slurry on one side of a polyethylene-based film (supplier: Mits...

Embodiment 2

[0036] a) Weigh 0.15Kg of dispersant (model: SN5040, supplier: Guangzhou Huixiang Chemical Co., Ltd.) and add it to 15Kg of pure water and stir until it is completely dispersed and uniform to form a dispersion. Take 0.12Kg of thickener (model: CMC1220 (supplier: Suzhou Fosai New Material Co., Ltd.) is added to the dispersion, and after stirring evenly, 10kg of nano-alumina powder (filler D50 = 0.95μm) is added to the solution to make slurry A, and the slurry A high-speed dispersion, after cooling to normal temperature, (weigh 1.33kg) low water absorption molecular weight is 1-50 million, solid content is 44-46% aqueous acrylic resin aqueous solution (model: BM-930B, supplier: Japan ZEON Co., Ltd.) into the dispersed slurry, fully stirred, after stirring evenly, the low-moisture slurry is prepared in this way;

[0037] b) Take a base film with a thickness of 16 μm, apply the low-moisture slurry on one side of the polyethylene-based film by micro-gravure roller coating, and the ...

Embodiment 3

[0039] a) Weigh 0.15Kg of dispersant (model: SN5040, supplier: Guangzhou Huixiang Chemical Co., Ltd.) and add it to 15Kg of pure water and stir until it is completely dispersed and uniform to form a dispersion. Take 0.12Kg of thickener (model: CMC1220 (supplier: Suzhou Fosai New Material Co., Ltd.) is added to the dispersion, and after stirring evenly, 10kg of nano-alumina powder (filler D50 = 0.95μm) is added to the solution to make slurry A, and the slurry A high-speed dispersion, after cooling to normal temperature, (weigh 1.33kg) low water absorption molecular weight is 1-50 million, solid content is 44-46% aqueous acrylic resin aqueous solution (model: BM-930B, supplier: Japan ZEON Co., Ltd.) into the dispersed slurry, fully stirred, after stirring evenly, the low-moisture slurry is prepared in this way;

[0040] b) Take a base film with a thickness of 16 μm, apply the low-moisture slurry on one side of the polyethylene-based film by micro-gravure roller coating, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com