Flue-cured tobacco upper leaf modulation method

A modulation method and flue-cured tobacco technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of curing loss, lax field management, heavy procurement tasks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

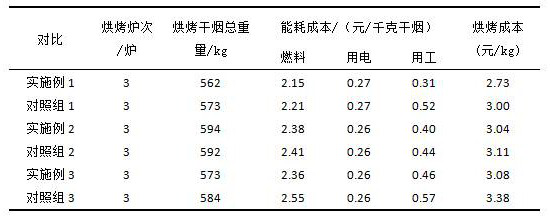

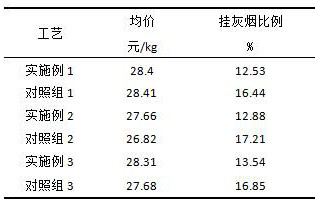

Embodiment 1

[0039] S100: According to the characteristics of the top leaves of the tobacco plant, such as mature spots, white and shiny main veins, and drooping leaf tips, the cut tobacco leaves are 4-6 pieces from the top, and the position is 10-15cm below the top. Harvested in Kunming Jijie Town, Xundian County, City, aimed at the K326 suitable ripe fresh tobacco leaves planted in this experiment, cut and harvested the rods with stems and put them in the furnace, with 35 tobacco plants per rod.

[0040] S200: Tobacco leaves that have been hung on the rods are pressed at 60kg / m 3 The density of the smoke is filled to 95% of the volume of the barn, and it is put into the air-flow up-and-down dense barn to be roasted.

[0041] S300: After a fire, rise to a dry bulb temperature of 32°C and a wet bulb temperature of 31°C within 3 hours, and stabilize the temperature for 8 hours, then increase the temperature at a rate of 1°C / 2h to a dry bulb temperature of 35°C, and a wet bulb temperature of...

Embodiment 2

[0048] S100: According to the characteristics of the top leaves of the tobacco plant, such as mature spots, white and shiny main veins, and drooping leaf tips, the cut tobacco leaves are 4-6 pieces from the top, and the position is 10-15cm below the top. Harvested in Kunming In Changhu Town, Shilin County, the NC102 suitable for ripening fresh tobacco leaves planted in this experiment was cut and harvested with stems and installed on poles, and 45 tobacco plants were hung on each pole.

[0049] S200: Tobacco leaves that have been hung on the rods are pressed at 70kg / m 3 The density of the smoke is filled to 97% of the volume of the barn, and it is put into the dense barn with descending air flow for roasting.

[0050] S300: After a fire, rise to a dry bulb temperature of 33°C and a wet bulb temperature of 32°C in 4 hours, and stabilize the temperature for 12 hours, then increase the temperature at a rate of 1°C / 2h to a dry bulb temperature of 38°C, and a wet bulb temperature o...

Embodiment 3

[0057] S100: According to the characteristics of the top leaves of the tobacco plant, such as mature spots, white and shiny main veins, and drooping leaf tips, the cut tobacco leaves are 4-6 pieces from the top, and the position is 10-15cm below the top. Harvested in Kunming Jijie Town, Xundian County, City, planted Yunyan 86 suitable for ripe fresh tobacco leaves for this experiment, cut and harvested with stems and hung poles for furnace installation, with 35 tobacco plants per pole.

[0058] S200: Tobacco leaves that have been hung on the rods are pressed at 65kg / m 3 The density of the smoke is filled to more than 96% of the volume of the barn, and it is loaded into the air-flow down-type dense barn to be baked.

[0059] S300: After a fire, rise to a dry bulb temperature of 33°C and a wet bulb temperature of 31°C within 5 hours, and stabilize the temperature for 10 hours, then increase the temperature at a rate of 1°C / 2h to a dry bulb temperature of 37°C, and a wet bulb tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com