Using method of electroslag remelting refining slag by efficiently using returned slag

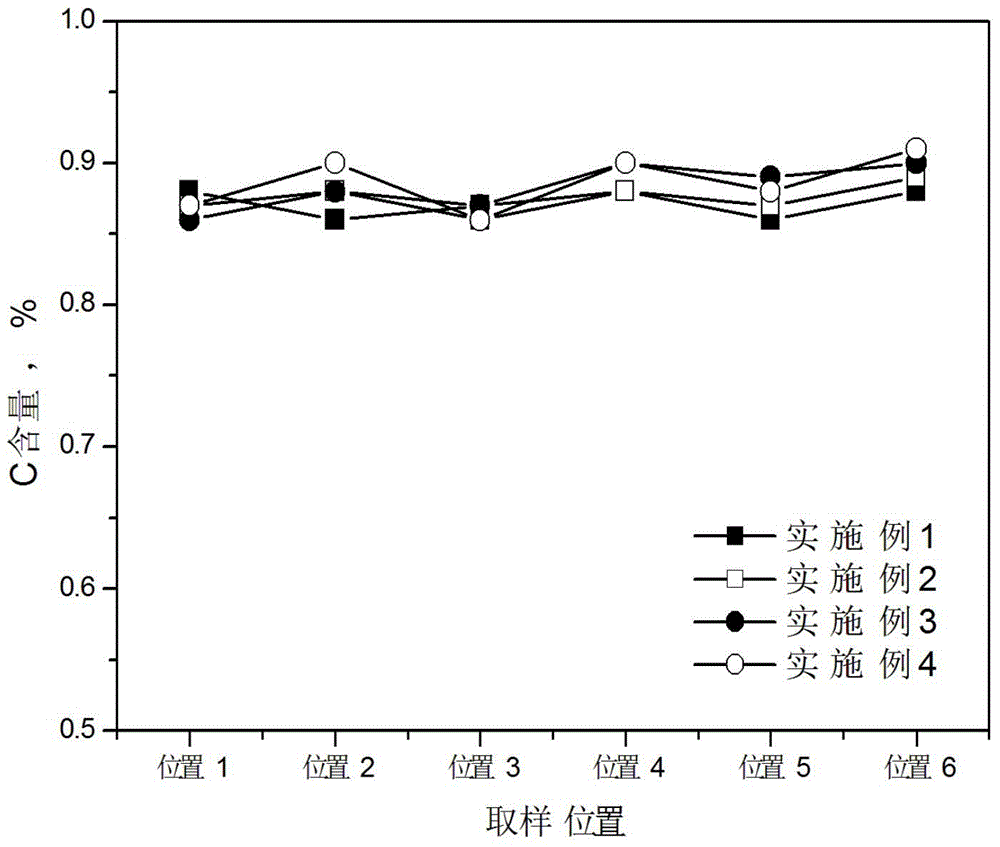

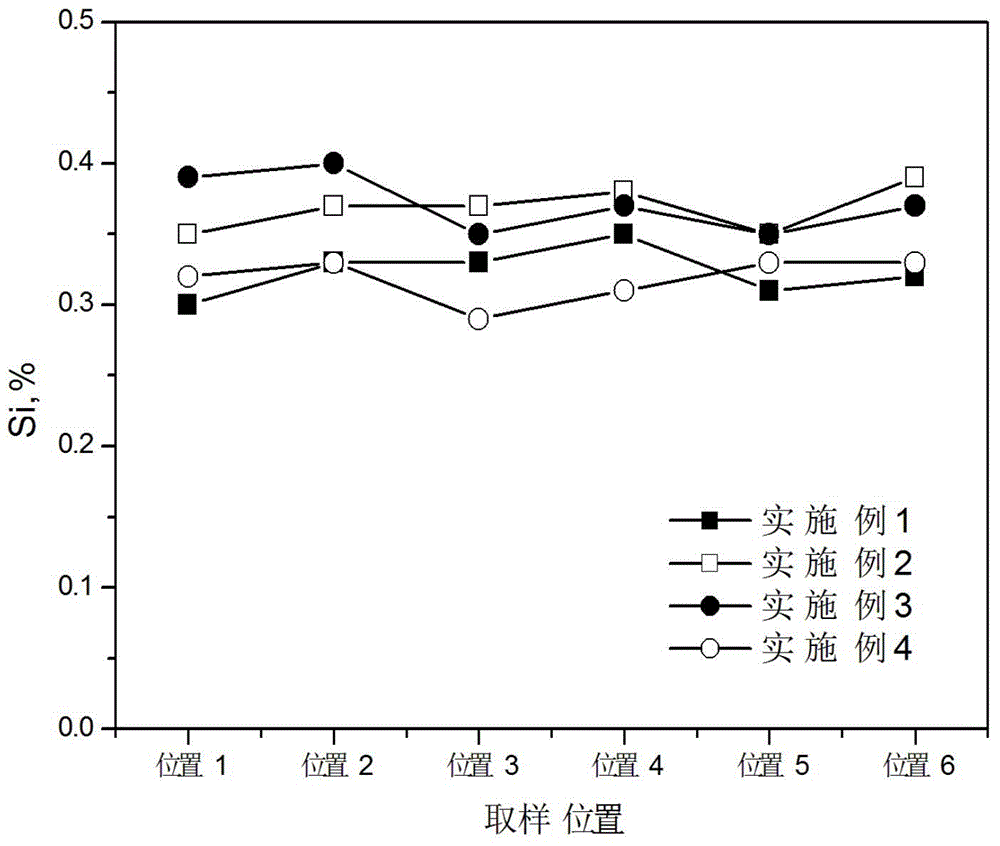

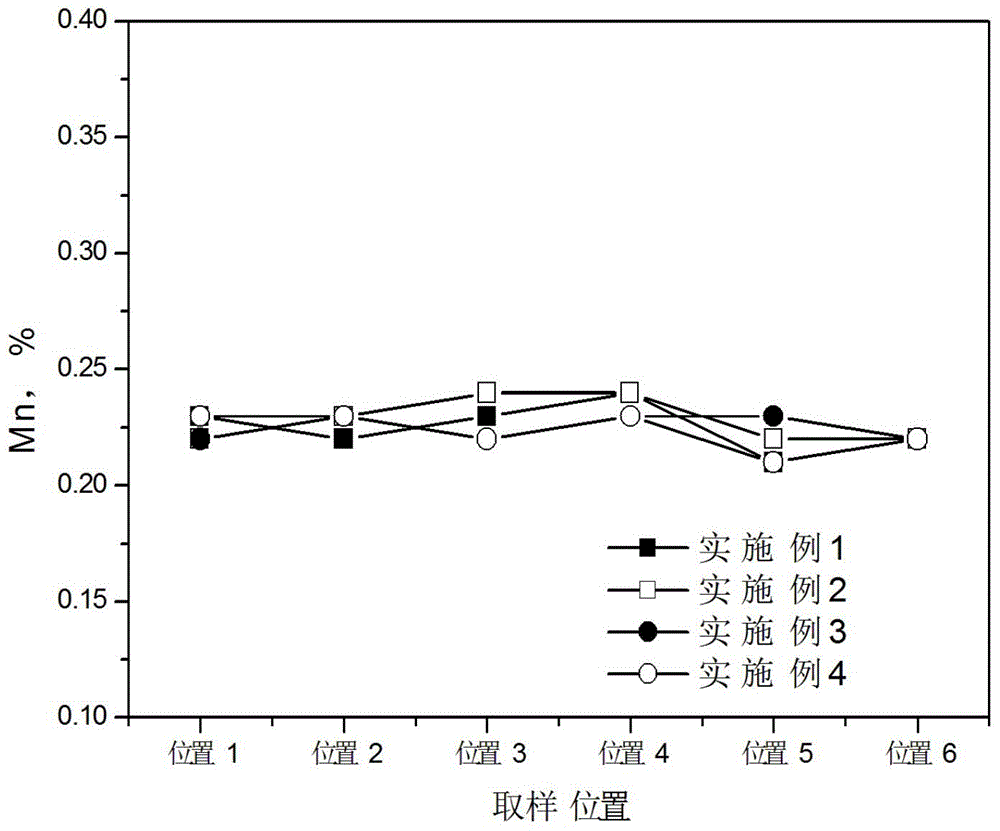

A technology of electroslag remelting and returning slag, which is applied in the field of electroslag remelting and refining slag, can solve the problems of unfavorable hydrogen content of electroslag ingots, unreasonable solutions, cumbersome preparation process, etc., and achieve uniform distribution of chemical components, surface The effect of good quality and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of electroslag remelting refining slag with high efficiency utilization of returned slag in this embodiment is composed of the following components in mass percentage: 50% of electroslag remelting returned slag, 35% of fluorite, 10% of alumina powder, and 5% of lime . Among them, CaF in fluorite 2 The mass percentage content of not less than 85%, SiO 2 The mass percentage content is 5 to 10%, and the Al in alumina powder 2 o 3 The mass percentage of CaO in lime is greater than 99%, and the mass percentage of CaO in lime is greater than 99%.

[0030] In this embodiment, a method for preparing electroslag remelting refining slag efficiently utilizing returned slag, the specific steps are as follows:

[0031] Step 1. Weigh the electroslag remelting return slag, fluorite, alumina powder, and lime according to the mass percentage, and crush the electroslag remelting return slag, fluorite, alumina powder, and lime into particle sizes of 10-30 mm granules, wherein:...

Embodiment 2

[0045] A kind of electroslag remelting refining slag with high efficiency utilization of returned slag in this embodiment is composed of the following components in mass percentage: 60% of electroslag remelting returned slag, 30% of fluorite, 8% of alumina powder, and 2% of lime . Among them, CaF in fluorite 2 The mass percentage content of not less than 85%, SiO 2 The mass percentage content is 5 to 10%, and the Al in alumina powder 2 o 3 The mass percentage of CaO in lime is greater than 99%, and the mass percentage of CaO in lime is greater than 99%.

[0046] In this embodiment, a method for preparing electroslag remelting refining slag efficiently utilizing returned slag, the specific steps are as follows:

[0047] Step 1. Weigh the electroslag remelting return slag, fluorite, alumina powder, and lime according to the mass percentage, and crush the electroslag remelting return slag, fluorite, alumina powder, and lime into particle sizes of 10-30 mm granules, wherein: ...

Embodiment 3

[0059] The electroslag remelting refining slag of this embodiment with high efficiency utilization of returned slag is composed of the following components in mass percentage: 70% of electroslag remelting returned slag, 24% of fluorite, and 6% of alumina powder. Among them, CaF in fluorite 2 The mass percentage content of not less than 85%, SiO 2 The mass percentage content is 5 to 10%, and the Al in alumina powder 2 o 3 The mass percentage content is greater than 99%.

[0060] In this embodiment, a method for preparing electroslag remelting refining slag efficiently utilizing returned slag, the specific steps are as follows:

[0061] Step 1. Weigh the returned slag from electroslag remelting, fluorite, and alumina powder according to the mass percentage, and break the returned slag from electroslag remelting, fluorite, and alumina powder into particles with a particle size of 10-30 mm, of which : The mass percentage of each component is: electroslag remelting return slag ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com