Waste extruder

A technology for extruders and garbage, applied in the direction of presses, manufacturing tools, etc., can solve problems such as affecting power generation efficiency and consuming kiln heat energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

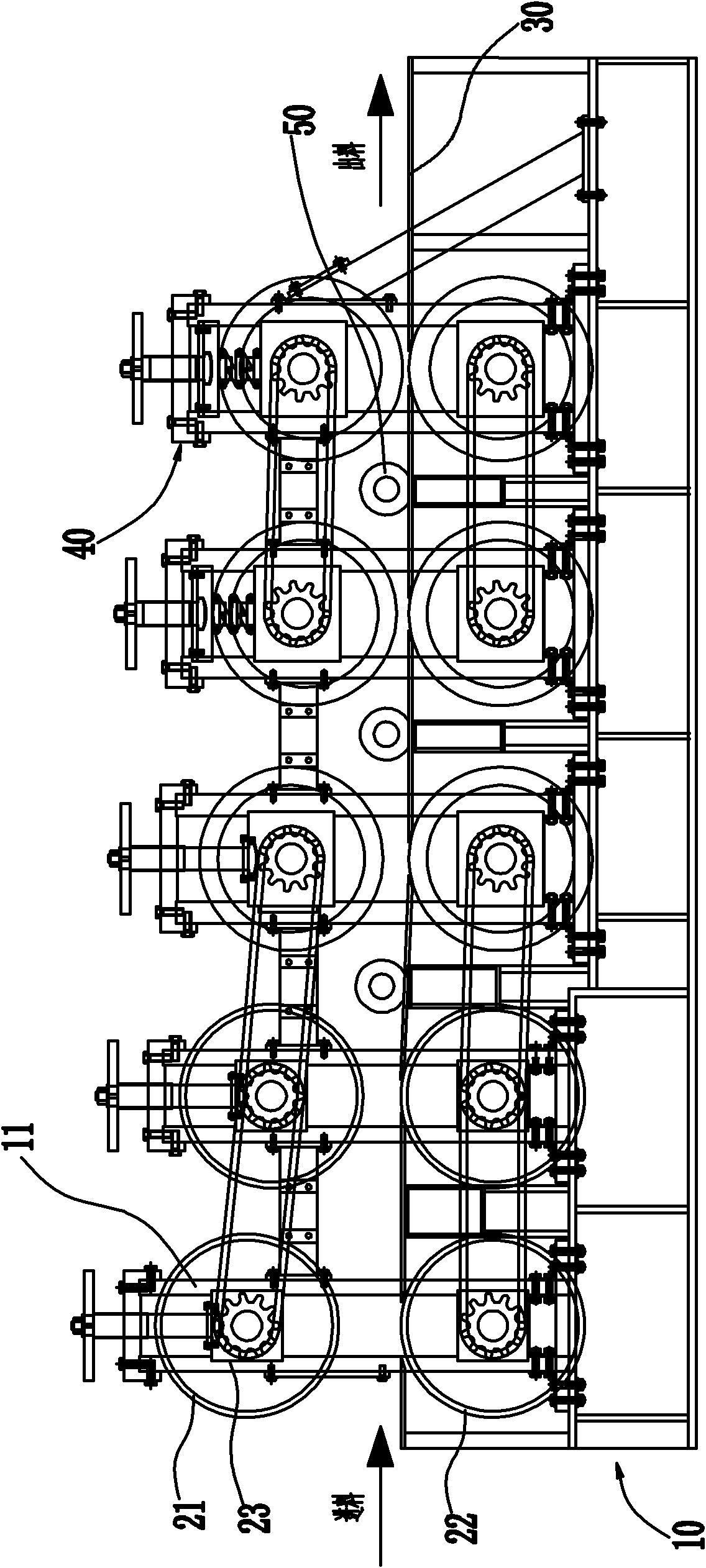

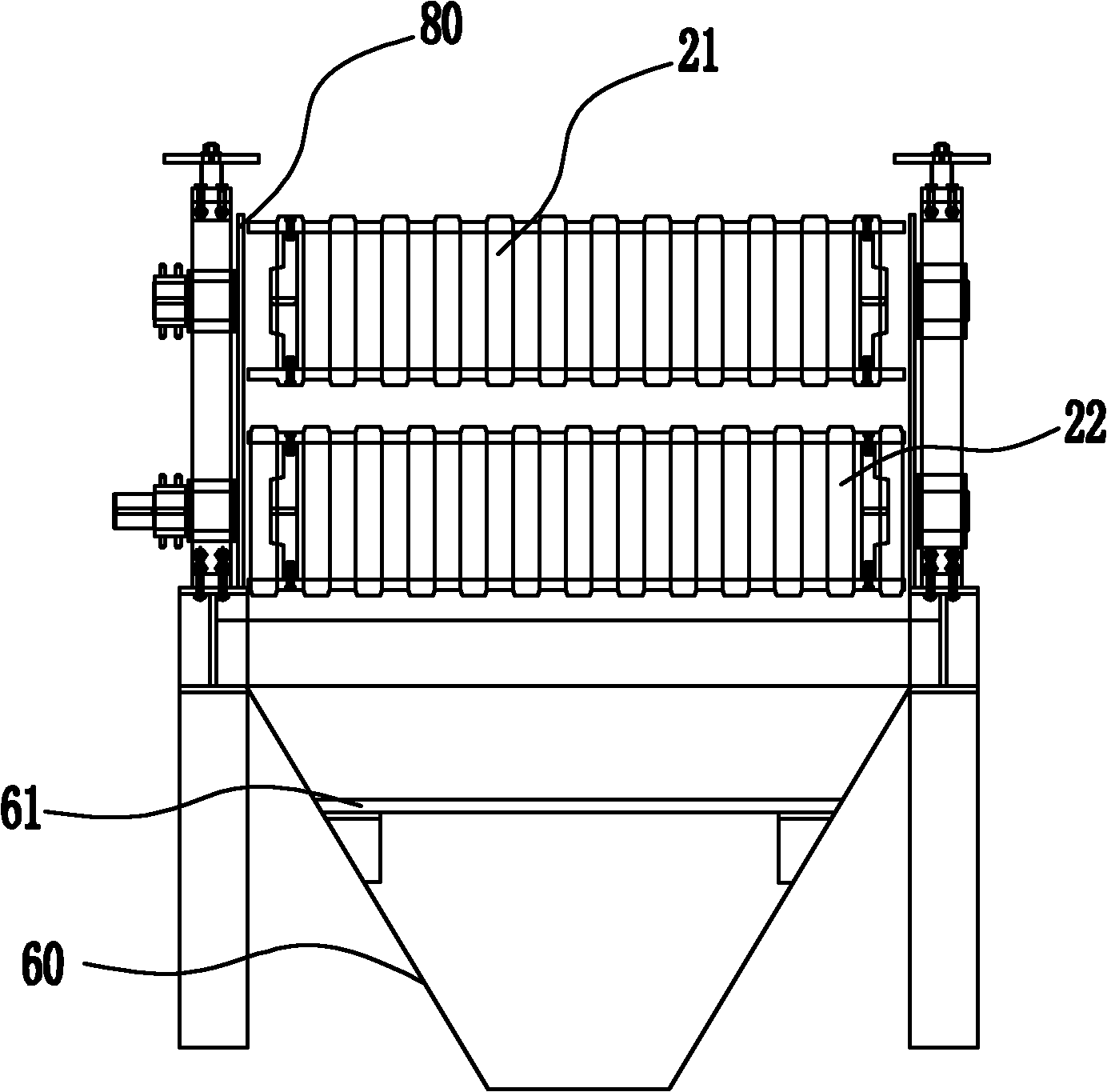

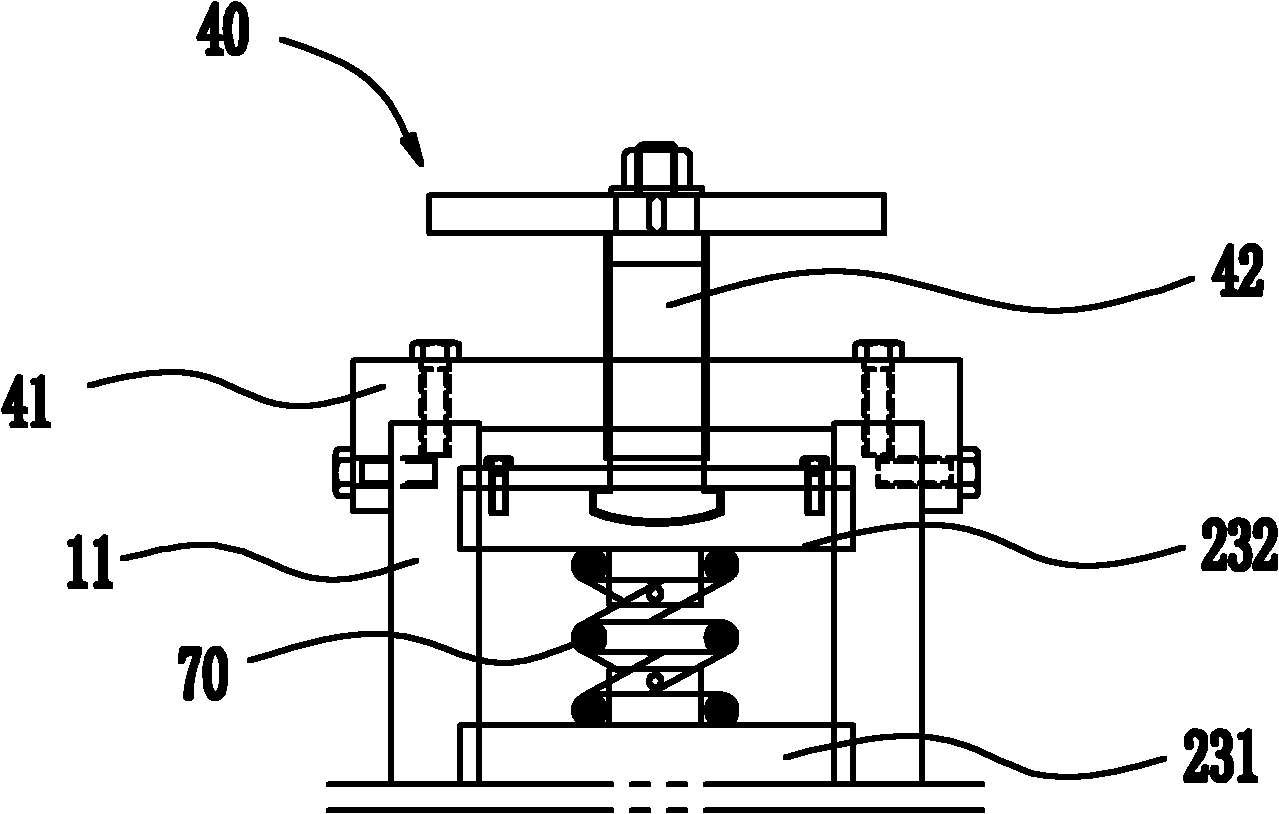

[0011] A garbage extruder, a frame 10 is provided with several groups of upper and lower pressure rollers 21, 22, and the distance between the rollers of each group of upper and lower pressure rollers 21, 22 is from the end of the feed port to the end of the discharge port. Arranging from large to small, there is a worktable 30 arranged in a flat manner on the frame 10 , and the upper end roll surface of the lower pressure roller 22 is exposed on the upper end plate surface of the workbench 30 . The upper and lower pressure rollers 21 and 22 are driven by the reducer to rotate, and the shafts of each group of pressure rollers are connected by chain transmission or belt transmission. The rubbish can be conveniently pushed along the working table 30 to be squeezed between the next set of pressing rollers.

[0012] Further, the working table 30 is composed of pallet units arranged at intervals between the lower pressing rollers 22, so that it will not affect the squeezing effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com