Biomass granular fuel applied to tobacco curing and application of biomass granular fuel

A biomass particle and fuel technology, applied in the fields of biofuel, waste fuel, application, etc., can solve the problems of serious air pollution, poor quality of flue-cured tobacco, high cost of flue-cured tobacco, and achieve the effect of less harmful components, low cost and environmental pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

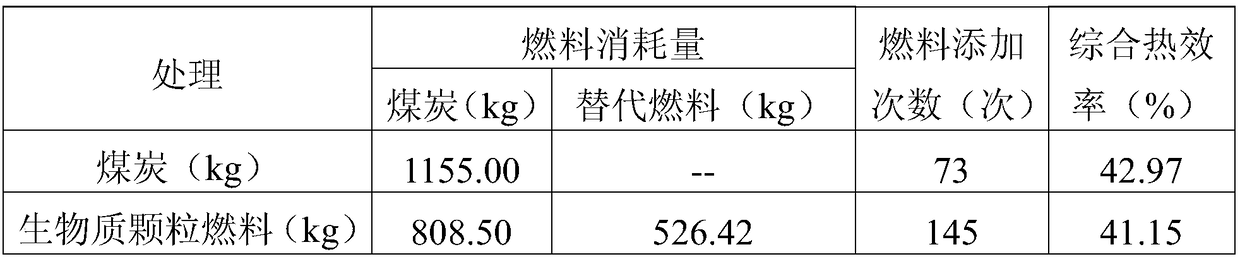

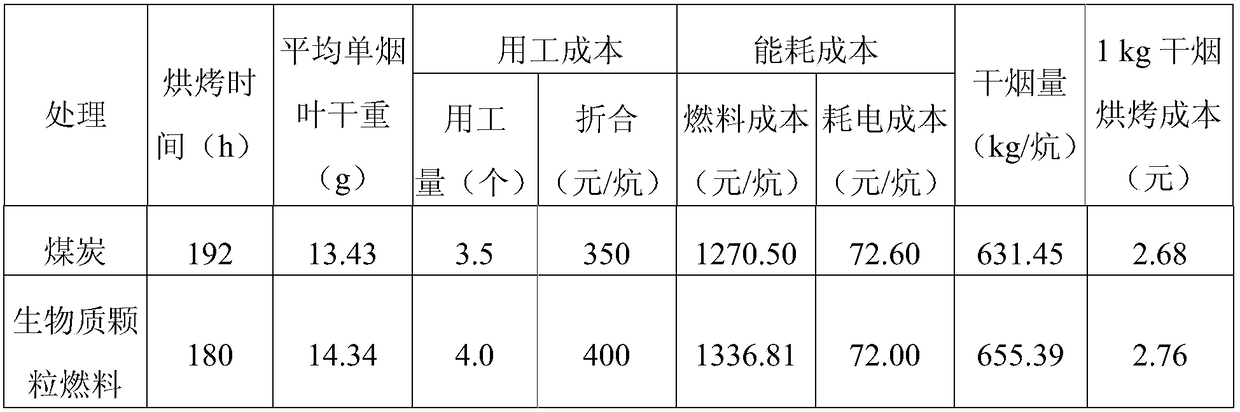

[0057] 1. Biomass formula screening test

[0058] In this experiment, 9 biomass formulations were set up, with 100% coal as CK, a total of 10 treatments: E1: 100% coal, E2: 100% sawdust, E3: 100% tobacco stem, E4: 100% tobacco stem, E5: 50% % wood chips + 50% tobacco stems, E6: 50% wood chips + 50% tobacco stems, E7: 50% tobacco stems + 50% tobacco stems, E8: 10% coal + 90% wood chips, E9: 10% coal + 90% tobacco Stem, E10: 10% coal + 90% tobacco stalk.

[0059] Biomass is mainly a high polymer composed of cellulose, hemicellulose and lignin, and the pyrolysis or combustion behavior of a single biomass can be considered as a comprehensive performance of these three main components. The biocomponents such as lignin, cellulose and hemicellulose in biomass fuel were determined by NREL method, and it was found that the content of cellulose, lignin and hemicellulose in 100% wood chips was the highest, followed by 50% sawdust + 50% tobacco stalk, compared with other biomass formula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com