Method for extracting diamond powder from water-based diamond liquid

A technology of diamond powder and diamond liquid, applied in the direction of diamond, etc., can solve the problems of systemic poisoning, human skin corrosion, and failure to recover diamond particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

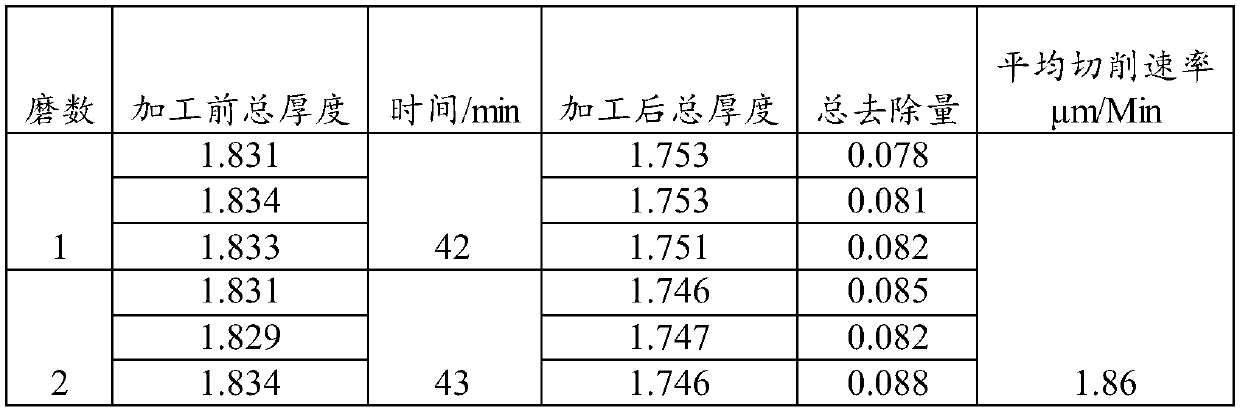

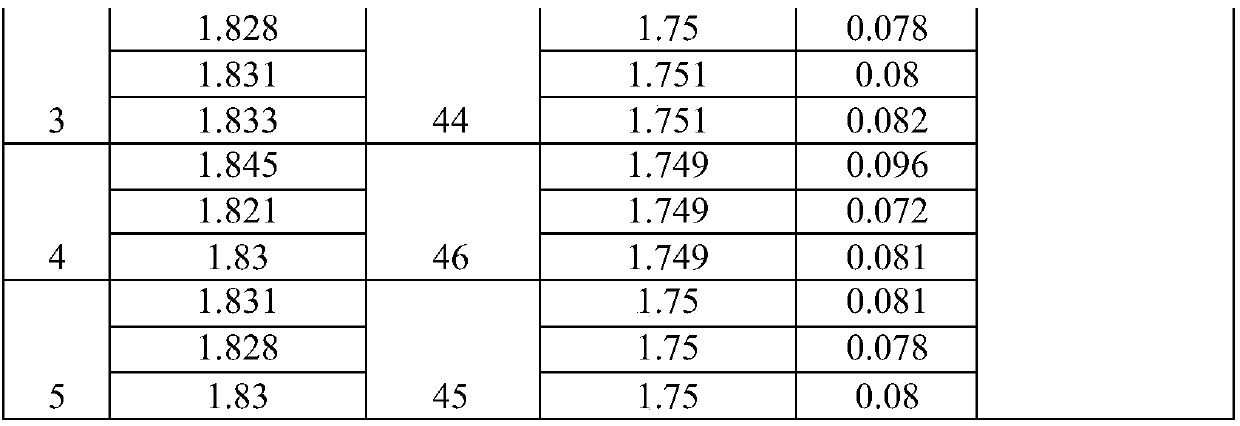

Examples

Embodiment 1

[0041] Collect the diamond waste liquid and filter it with a 500-mesh screen;

[0042] Add concentrated hydrochloric acid with a mass fraction of 24.1%, and the mass of concentrated hydrochloric acid is twice the mass of the filtered diamond waste liquid; stir for half an hour, let stand for 4 hours after fully reacting; collect the liquid enriched with diamond powder in the lower layer;

[0043] The acidified diamond powder enrichment solution was washed with water and washed with a large amount of deionized water for 3 times; after each washing and separation, the diamond powder enrichment solution in the lower layer was collected; the conductivity of deionized water was 3.05 μs / cm;

[0044] Add a sodium hydroxide solution with a volume fraction of 5% and a concentration of 2.5mol / L, the quality of the sodium hydroxide solution is 3 times that of the diamond powder enrichment solution, and then separate and collect the lower diamond powder enrichment solution;

[0045] Wash ...

Embodiment 2

[0050] Collect the diamond waste liquid and filter it with a 500-mesh screen;

[0051] Add concentrated hydrochloric acid with a mass fraction of 20.24%, and the mass of concentrated hydrochloric acid is twice the mass of the filtered diamond waste liquid; stir for half an hour, let stand for 4 hours to separate the liquid after fully reacting; collect the liquid enriched with diamond powder in the lower layer;

[0052] The acidified diamond powder enrichment solution was washed with water and washed with a large amount of deionized water for 3 times; after each washing and separation, the diamond powder enrichment solution of the lower layer was collected; the conductivity of deionized water was 3.05 μs / cm;

[0053] Adding a sodium hydroxide solution with a volume fraction of 7% and a concentration of 4mol / L, the quality of the sodium hydroxide solution is 3 times that of the diamond powder enrichment solution, and then separates and collects the lower diamond powder enrichmen...

Embodiment 3

[0059] Collect the diamond waste liquid and filter it with a 500-mesh screen;

[0060] Add concentrated hydrochloric acid with a mass fraction of 25%, and the mass of concentrated hydrochloric acid is twice the mass of the filtered diamond waste liquid; stir for half an hour, let stand for 4 hours after fully reacting; collect the liquid enriched with diamond powder in the lower layer;

[0061] The acidified diamond powder enrichment solution was washed with water and washed with a large amount of deionized water for 3 times; after each washing and separation, the diamond powder enrichment solution in the lower layer was collected; the conductivity of deionized water was 3.05 μs / cm;

[0062] Adding a sodium hydroxide solution with a volume fraction of 6% and a concentration of 2mol / L, the quality of the sodium hydroxide solution is 3 times that of the diamond powder enrichment solution, and then separates and collects the lower diamond powder enrichment solution;

[0063] Wash...

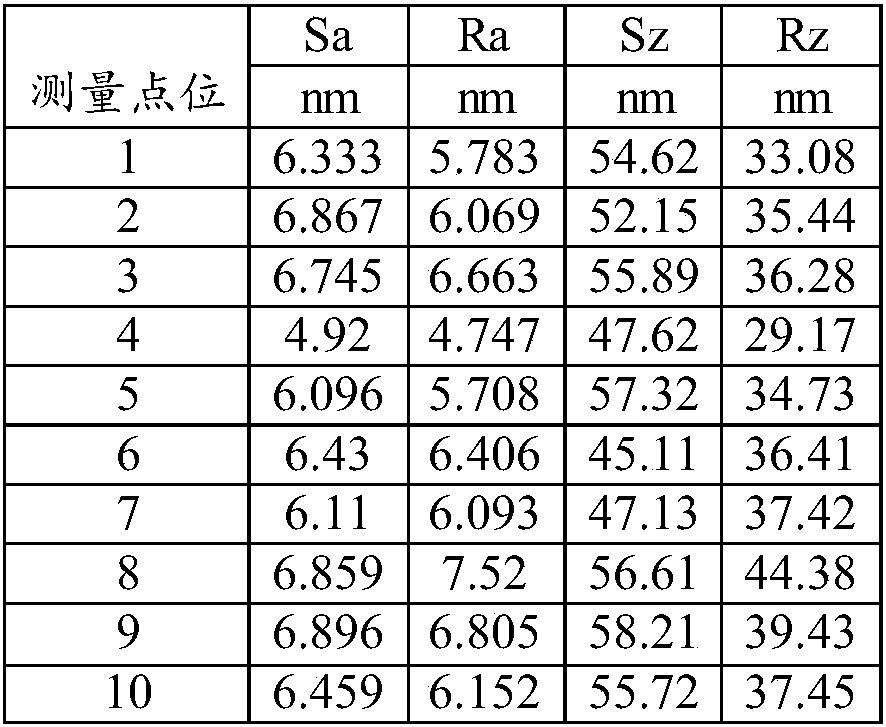

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com