Intelligent control system for temperature and humidity uniformities of concrete curing room

A technology of intelligent control system and intelligent controller, which is applied in control/regulation system, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problems of controller corrosion and damage, unreachable humidity control, human error, etc. To achieve the effect of uniform humidity and avoid humidity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

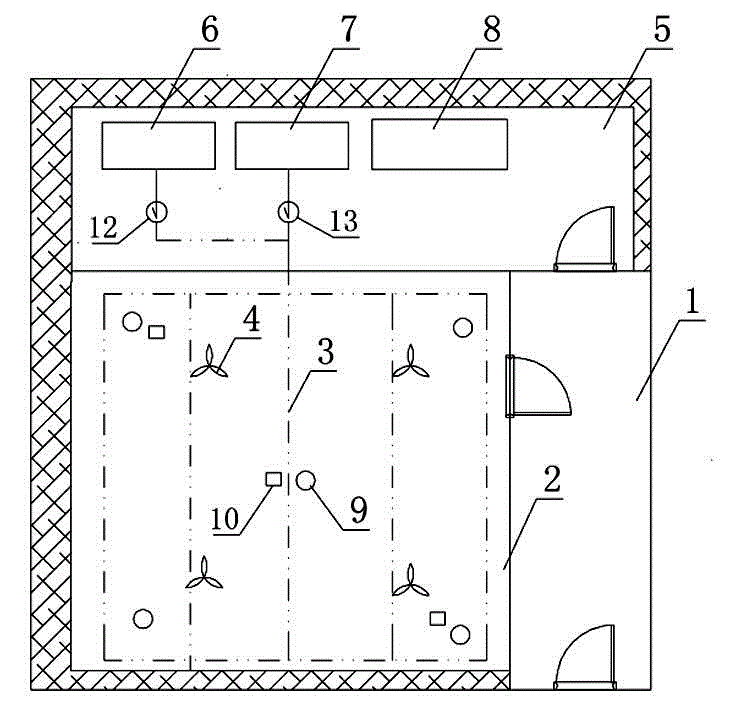

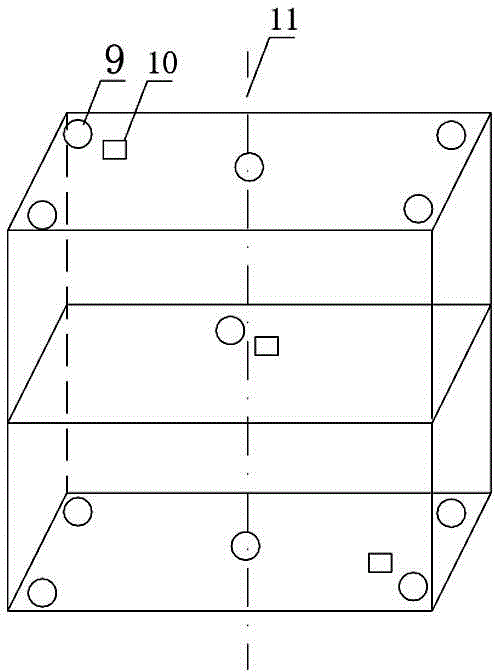

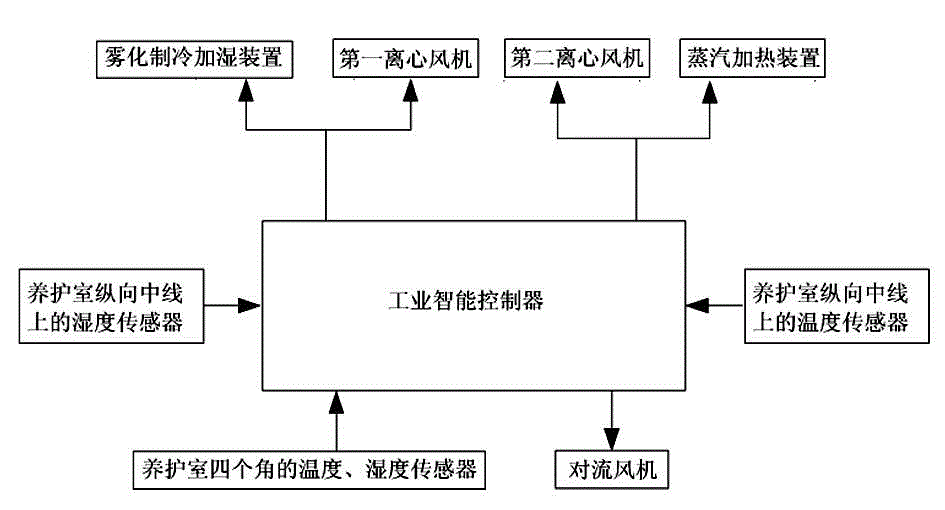

[0011] Such as Figure 1-3 As shown, the intelligent control system for concrete curing room temperature and humidity uniformity according to the present invention includes a curing room 2 provided with a buffer room 1 outside the entrance, and a constant temperature water vapor pipeline provided with a plurality of air outlets on the upper part of the curing room 2 3 and the convection fan 4, and the atomization cooling and humidifying device 6, the steam heating device 7 and the industrial intelligent controller 8 arranged in the control room 5; a temperature sensor 9 and a humidity sensor 10 are arranged in the curing room 2; the temperature The sensors 9 are respectively arranged at the top, middle, and lower corners of the curing room 2 and the top, middle, and lower positions of the longitudinal centerline 11 of the curing room; the humidity sensors 10 are respectively arranged at the two opposite corners of the top and lower parts of the curing room and the middle posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com