Servo punching main transmission device of numerical control turret punch press

A technology of CNC turret punch press and main drive, applied in the field of servo stamping main drive, can solve the problems of oil pollution, difficult maintenance, high energy consumption, etc., and achieve the effects of low noise, high transmission efficiency and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

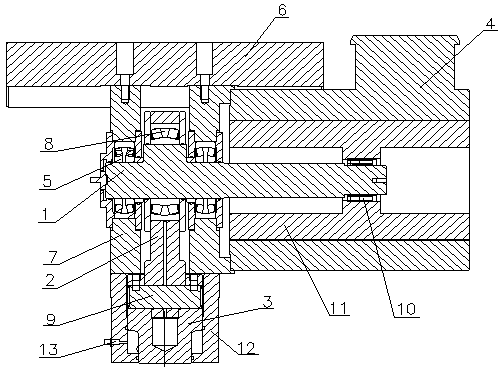

[0018] A servo stamping main transmission device of a CNC turret punching machine, including a crankshaft 1, a connecting rod 2, a punch 3 and a servo motor 4, one end of the crankshaft 1 is installed on the support under the bottom plate 6 through two self-aligning roller bearings 5 On the plate 7, the upper end of the connecting rod 2 is connected to the crankshaft 1 through a cylindrical roller bearing 8, the lower end of the connecting rod 2 is connected to the punch 3 through a pin 9, and the other end of the crankshaft 1 is connected to the rotor 11 of the servo motor 4 through an expansion sleeve 10, The punch 3 is located in the guide seat 12 below the support plate 7 .

[0019] The punch 3 described in the present invention is in an inverted convex shape, and the bottom surface of the guide seat 12 is provided with a middle hole. Coordinated, the lower end sidewall of the guide seat 12 is provided with an air hole 13, and the air hole 13 communicates with an air sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com