Numerically controlled capstan punch with double screw driven Y-axle

A technology of CNC turret punching machine and double screw rod, which is applied in the direction of metal processing machinery parts, metal processing equipment, feeding devices, etc., can solve the problems of unbalanced load and force, affecting processing accuracy, etc., and achieve stable conveying, high processing accuracy, Good effect on feed dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

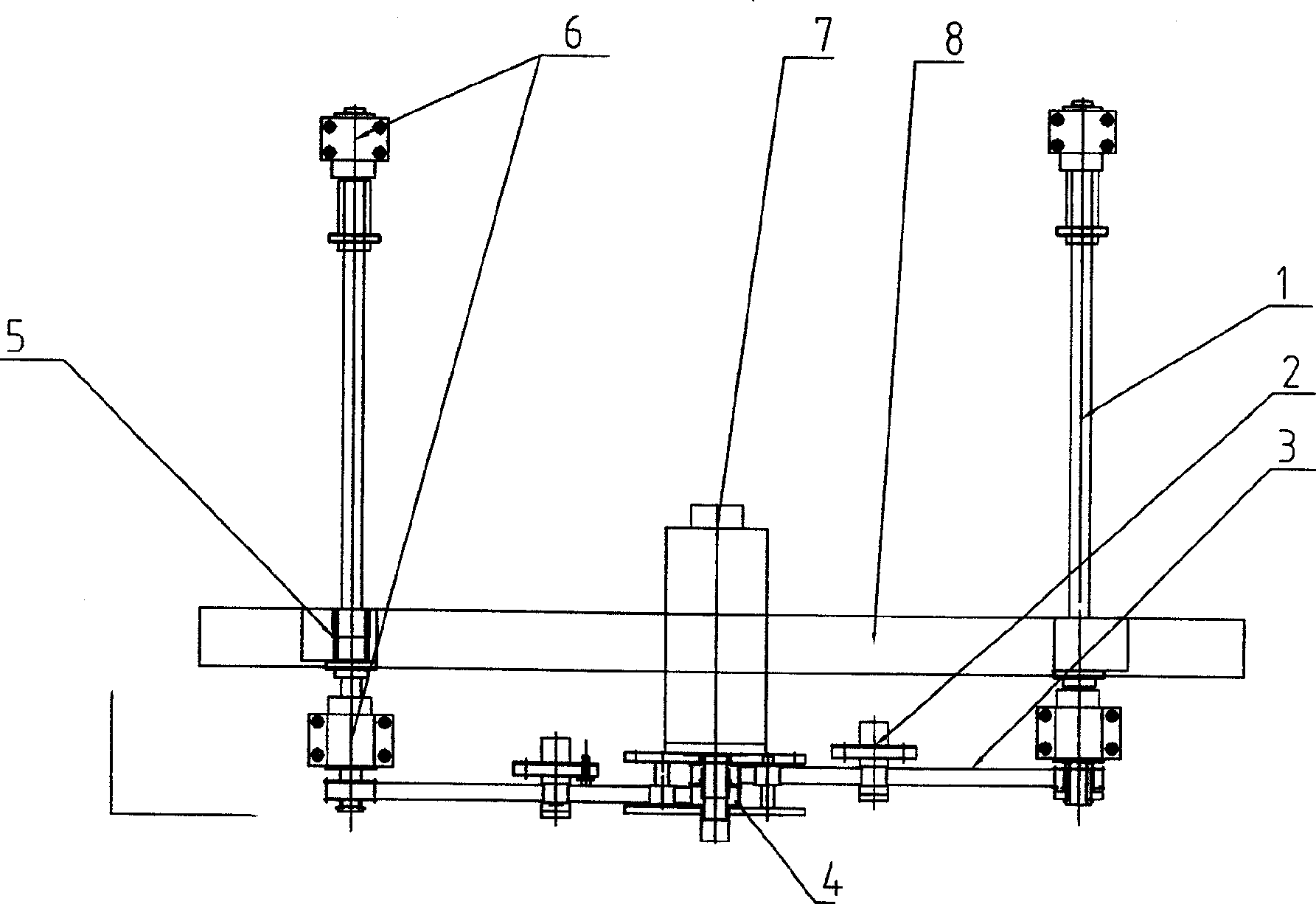

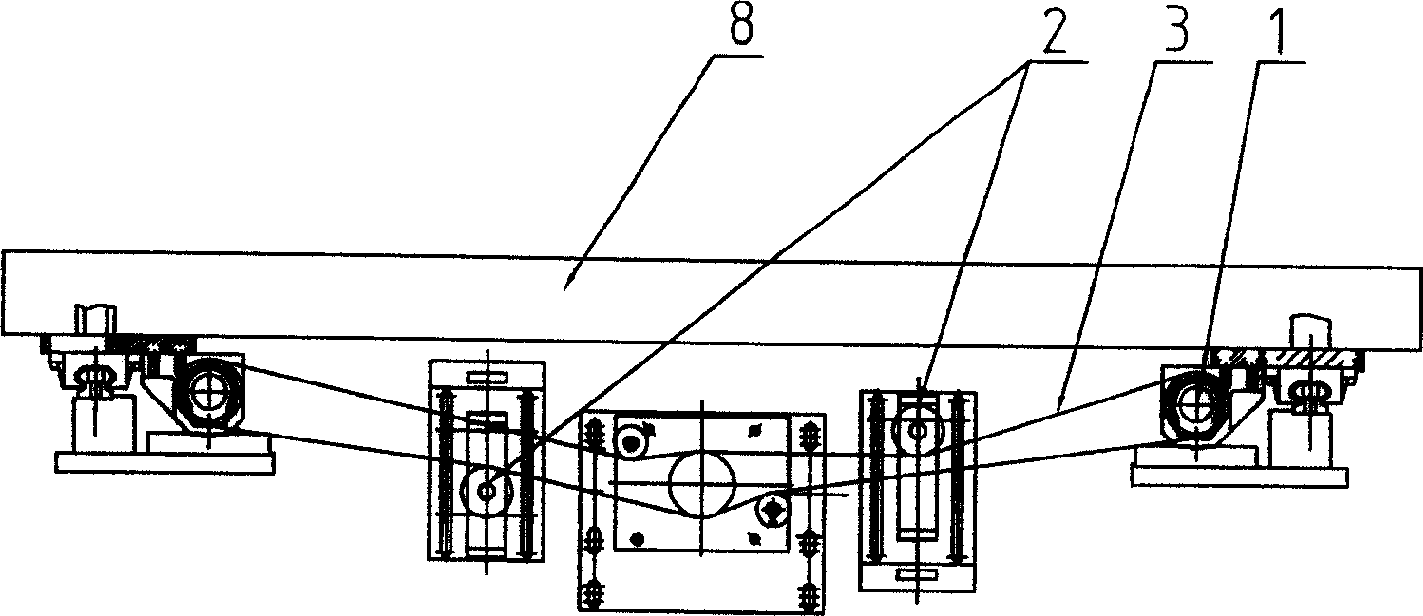

[0010] As shown in the figure, the CNC turret punching machine driven by Y-axis double screw rods includes a beam 8, on which a nut seat 5 is arranged, and a screw rod 1 is fixed on the machine body through a bearing 6, and the screw rod 1 is in phase with the nut seat 5 Adaptation, the motor 7 is also fixed on the fuselage, the screw rod 1 and the nut seat 5 have two sets, the nut seat 5 is symmetrically arranged on the left and right sides of the beam 8, the two screw rods 1 are arranged parallel to each other, and the shaft end of the motor Connect with two screw mandrels 1 respectively through synchronous pulley 4 and left and right synchronous belt 3. A pulley tensioning device 2 is provided on the side of the synchronous belt 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com