Mechanical servo drive main transmission device for digital turrent punch press

A numerically controlled turret punch press and mechanical servo technology, applied to punching machines, presses, manufacturing tools, etc., can solve problems such as difficult, complex mechanical structures, and high motor power, and achieve low manufacturing costs, good dynamic characteristics, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

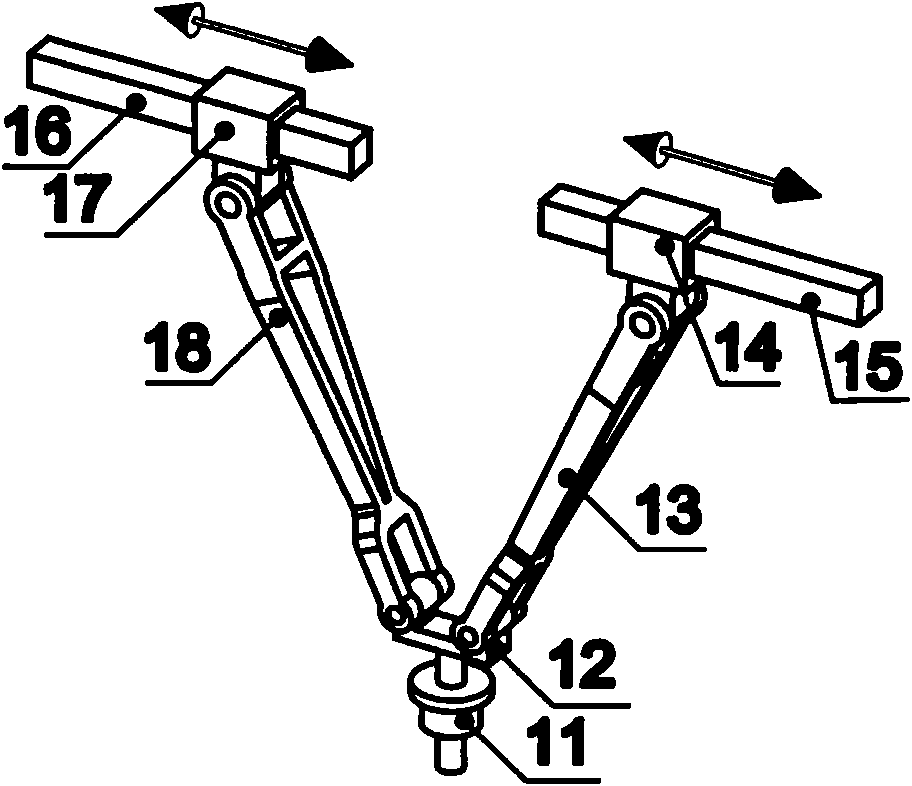

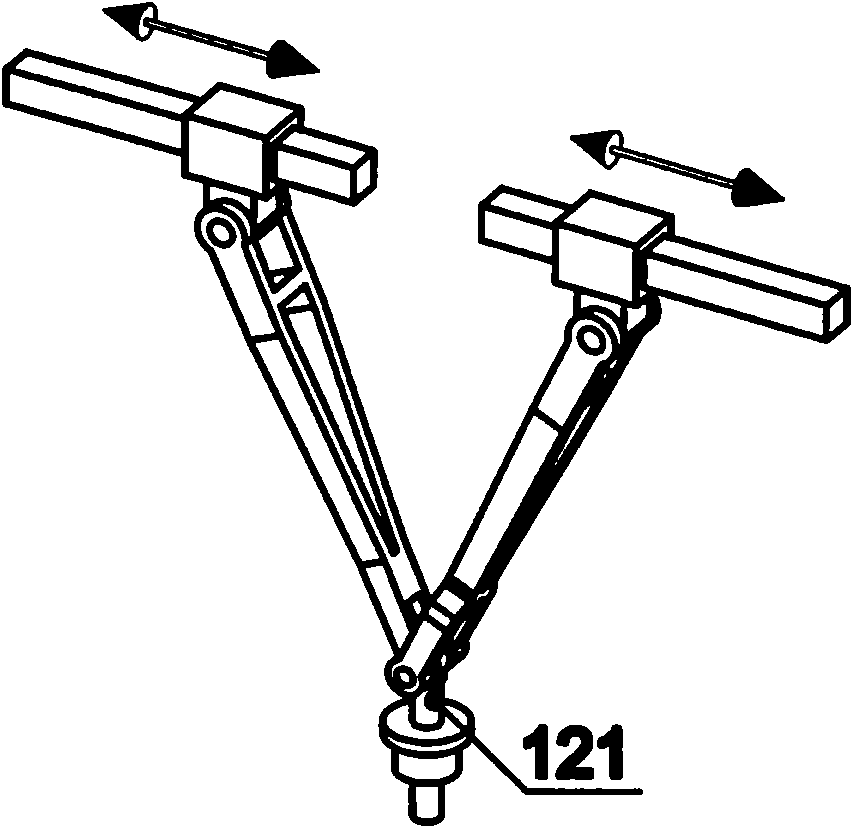

[0024] The structure of a mechanical servo-driven main transmission device for a CNC turret punch press in this embodiment is as follows: figure 1 Shown, comprise fixed platform 15,16, a moving platform 12 that punches are installed, connect described moving platform 12 and the first and second branch chain between fixed platform 15,16 and one and described fixed platform 15, 16 fixedly connected guide sleeve 11 (the guide sleeve 11 and the fixed platforms 15 and 16 are fixed to the bed), the kinematic pair and the servo motor to limit the movement direction of the moving platform 12; the first and second branch chains include: sliders 14, 17 and connecting rods 13, 18; there are four kinematic pairs: one is a moving pair connected between fixed platforms 15, 16 and slide blocks 14, 17, and the moving pair is actively driven by a servo motor; It is a rotary pair connected between the sliders 14, 17 and the connecting rods 13, 18; one is a rotary pair connected between the conn...

Embodiment 2

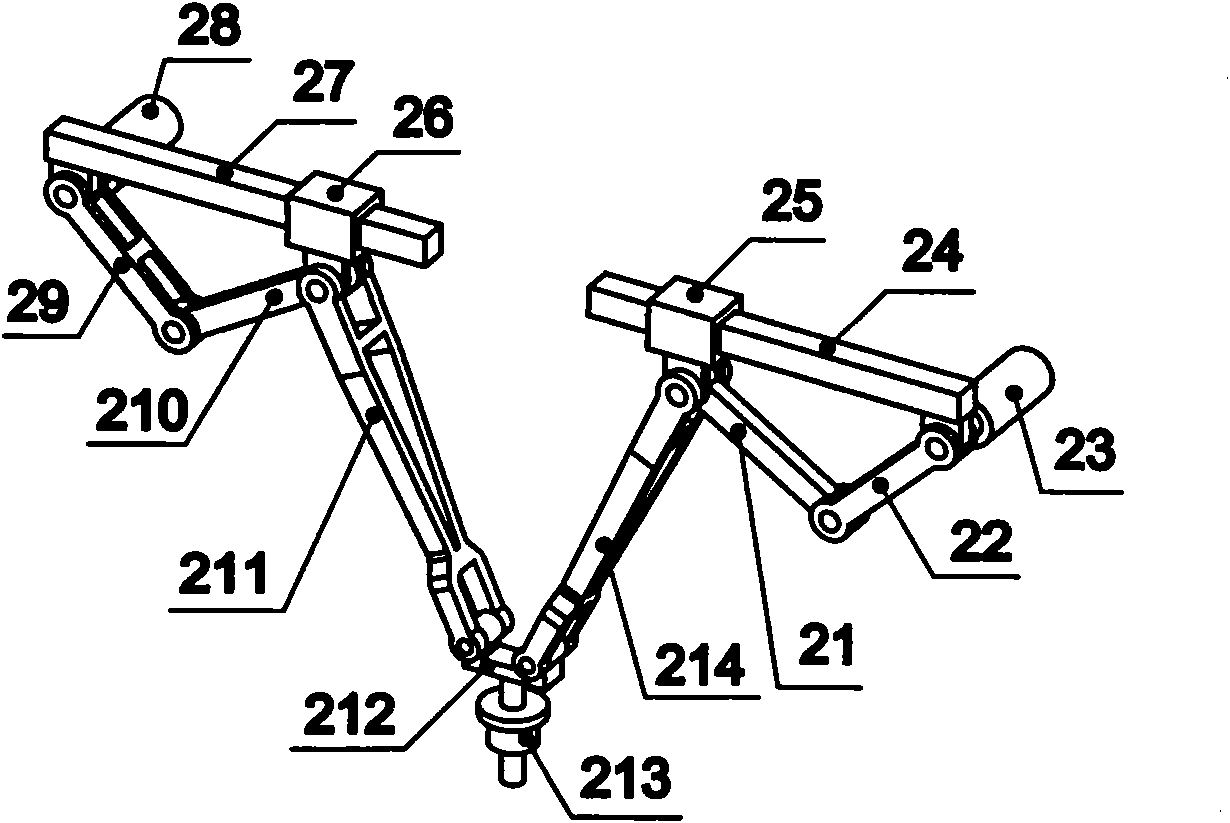

[0029] The structure of a main transmission device used for the CNC turret punch machine servo drive in this embodiment is as follows: image 3 As shown, it includes a fixed platform 24, a fixed platform 27, a moving platform 212 for installing a punch, connecting the first and second branch chains between the moving platform 212 and the fixed platforms 24, 27, and a fixed platform connected to the fixed platform. 24, 27 are fixedly connected to the guide sleeve 213 (the guide sleeve 213 and the fixed platforms 24, 27 are fixed to the bed), the kinematic pair, and the servo motors 23, 28; the first and second The branch chain includes: crank 22, crank 29, upper connecting rod 21, upper connecting rod 210, slider 25, slider 26, connecting rod 211, connecting rod 214; there are seven kinematic pairs: one is connected to the fixed platform 24,27 and cranks 22,29, and the rotary pair is actively driven by servo motors 23,28; one is a rotary pair connected between cranks 22,29 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com