Metal plate producing process

A processing technology, metal sheet technology, applied in metal processing equipment, manufacturing tools, laser welding equipment and other directions, can solve problems such as low efficiency, poor workpiece position accuracy, secondary clamping, etc., to improve dimensional accuracy and position accuracy, The effect of improving production efficiency and simplifying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

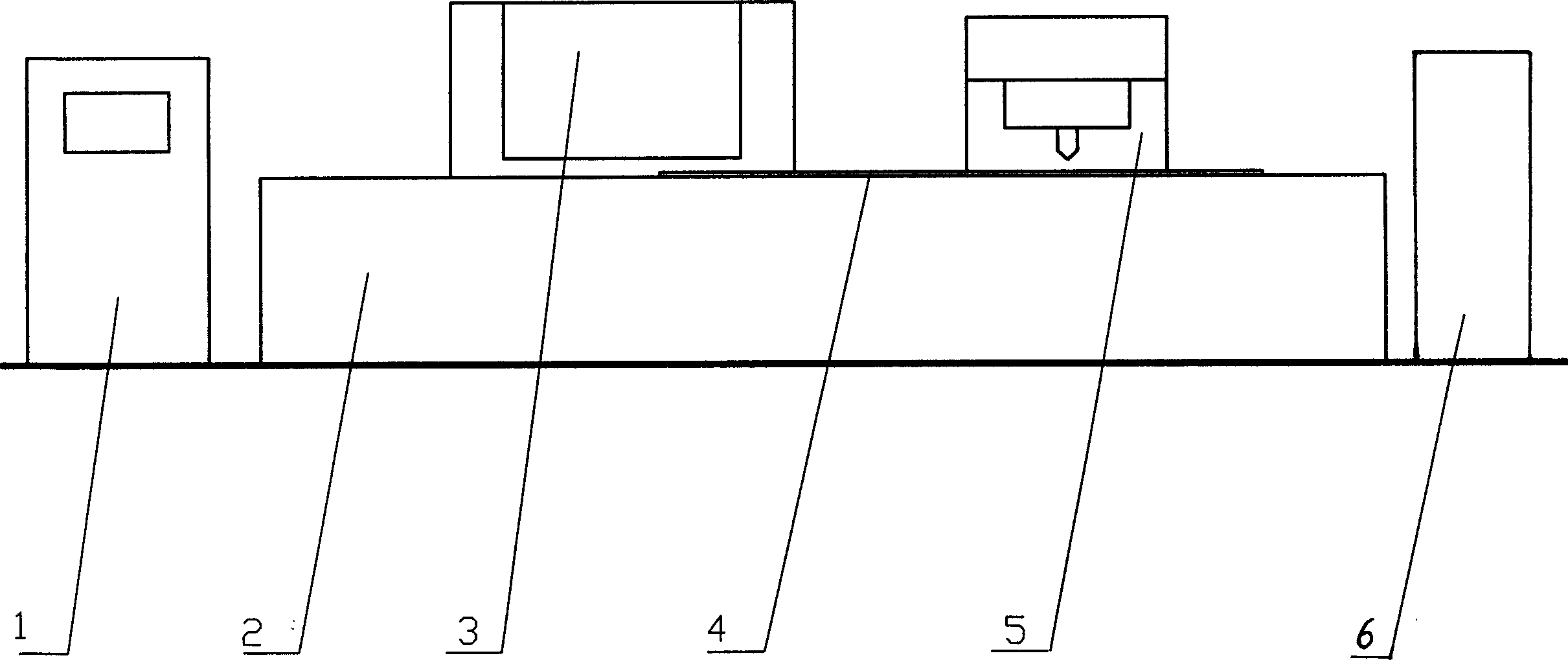

[0012] The accompanying drawings show a schematic diagram of the structure of the present invention. According to the process method of the present invention, a punching compound machine integrating the functions of a CNC turret punch and a CNC laser cutting machine is designed and manufactured. It consists of a control system 1, a worktable 2, a turret punch 3, a laser cutting head 5 and The laser generator 6 is composed. The control system 1 controls the feed device of the worktable 2 and the movement of the turret punch 3 and the laser cutting head 5; the laser generator 6 is connected with the laser cutting head 5 to provide laser for the laser cutting head 5, The turret punch 3 and the laser cutting head 5 are on the same side of the worktable. Fix the entire steel plate 4 on the workbench 2, and input the graphics and quantity of the parts to be processed into the control system 1. Under the control of the control system 1, the turret punch 3 first completes regular, small-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com