Servo main transmission device for novel numerical control turret punch press

A technology of CNC turret punch press and main drive, which is applied to punching machines, presses, manufacturing tools, etc., can solve the problems of high price of CNC turret punch press, difficulty in dynamic balance control, and many motion links, etc. Simple structure and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

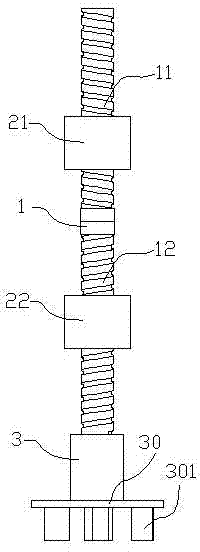

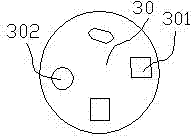

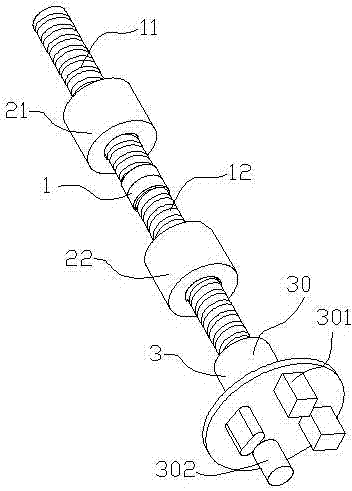

[0022] The invention as Figure 1-4 As shown: the stamping machine tool includes a controller, a body 4 and a punch 3, the punch 3 is connected to the body 4 through a forward and reverse screw drive mechanism, and the forward and reverse screw drive mechanism includes a screw 1 with forward and reverse threads, respectively Nut 1 21 movably connected with threaded section 1 11 on screw 1 and nut 2 22 movably connected with threaded section 2 12 on screw 1, and drive motors 1 and 2 that drive nuts 1 21 and 2 22 to do forward and reverse rotation;

[0023] The punch 3 is fixedly connected to the bottom of the screw 1; and can move up and down and rotate with the lead screw (screw 1);

[0024] Described nut one 21 and nut two 22 are movably connected on the body 4, and only retain its degree of freedom of rotation around its own axis; this connection mode can adopt multiple specific structural forms, such as: bearings are set on the body 4, Set constraint grooves, etc.; as long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com