Main drive mechanism of flexible numerical control turret punch press and working method

A technology of CNC turret punching machine and working method, which is applied in the field of main transmission mechanism of flexible CNC turret punching machine, can solve the problems of large support bearing load, poor controllability, and slow punching speed, and achieve high punching speed and punching speed Easy adjustment of cutting force and mechanical properties, and the effect of expanding processing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Embodiment 1: The threaded auxiliary driving part includes a motor and a synchronous belt driven by the motor, and one end of the synchronous belt is sleeved on the outer periphery of the nut.

Embodiment 2

[0059] Embodiment 2: The screw thread auxiliary driving part is gear transmission.

Embodiment 3

[0060] Embodiment 3: The screw thread auxiliary driving part is a combination of an air cylinder or an electric cylinder and a crank.

[0061] The swinging frame is arranged between the crank connecting rod mechanism and the thread pair, and the swinging frame is respectively hinged with the frame, the crank connecting rod mechanism and the thread pair.

[0062] The structural forms of the swing frame can be various, and preferably have the following preferred embodiments:

[0063] first embodiment

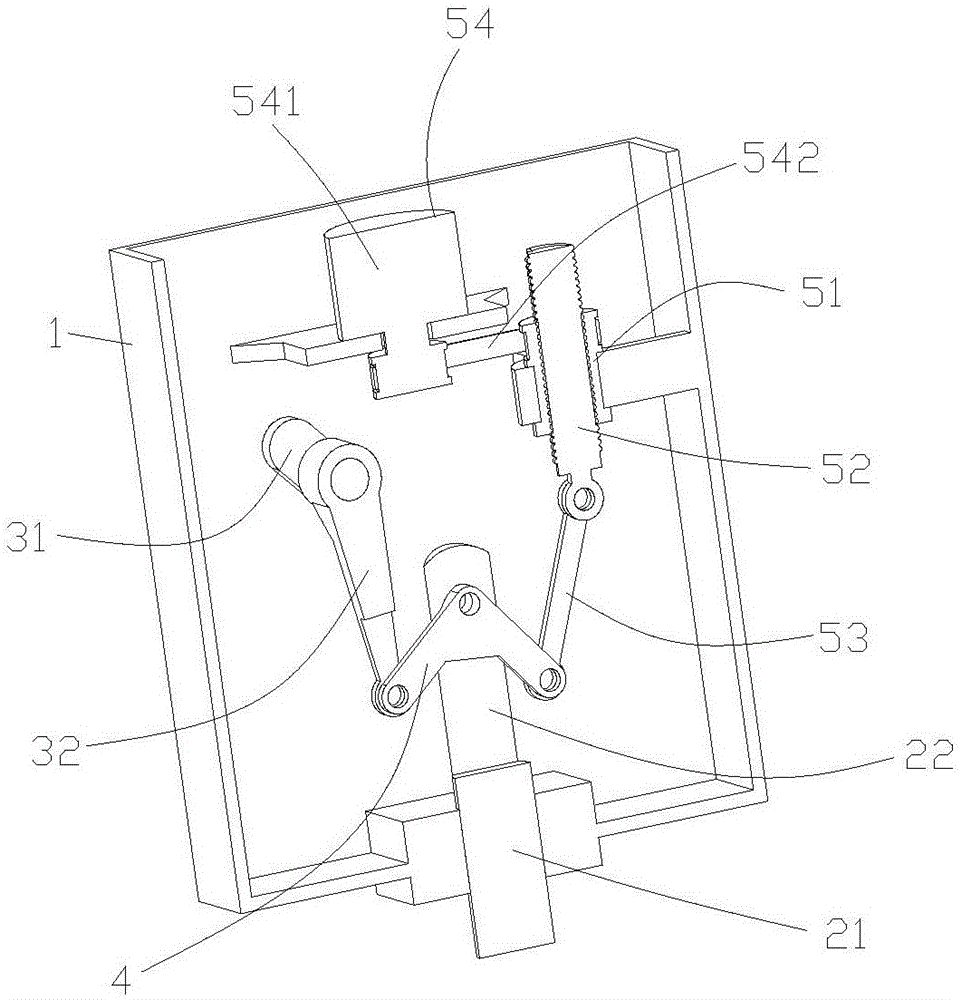

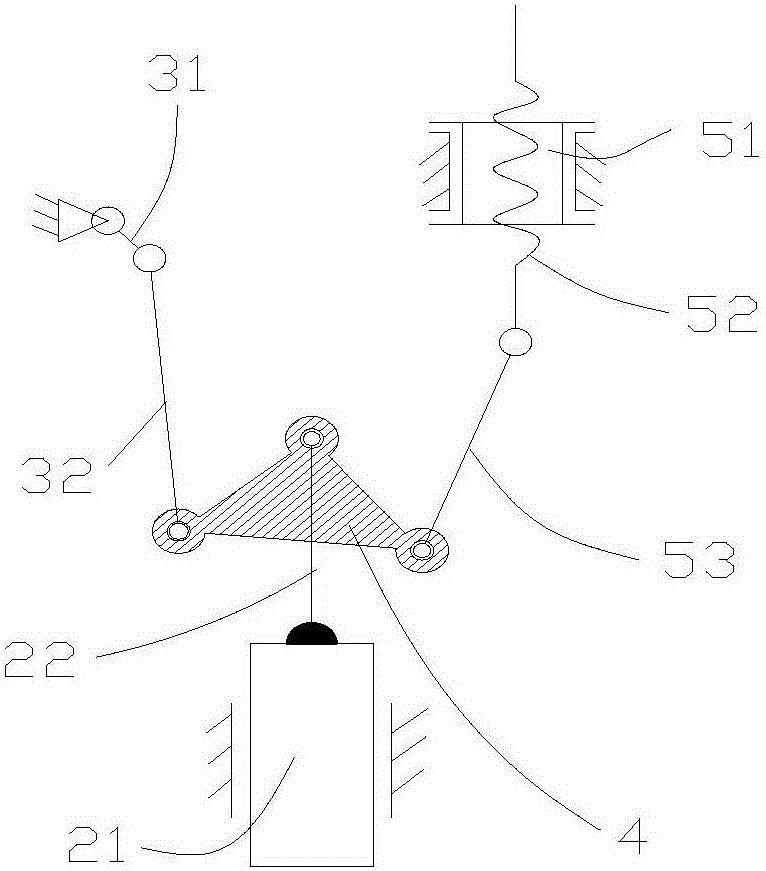

[0064] like figure 1 and figure 2 As shown, the swing frame is L-shaped, the tip corner of the L-shaped swing frame faces upward, and the tip corner is hinged to the top of the vertical connecting rod. One of the free ends of the L-shaped swing frame is hinged with the connecting rod in the crank-link mechanism; the other free end of the L-shaped swing frame is hinged with the support rod in the threaded pair.

[0065] Second embodiment

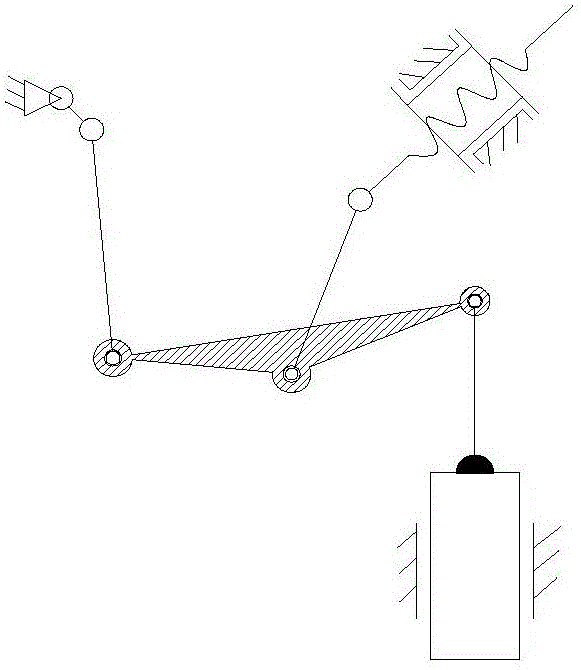

[0066] like image 3 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com