System for detecting wear of mould of numerical control turret punch press on line and working method thereof

A technology of CNC turret punch press and detection system, which is applied in the direction of metal processing, manufacturing tools, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

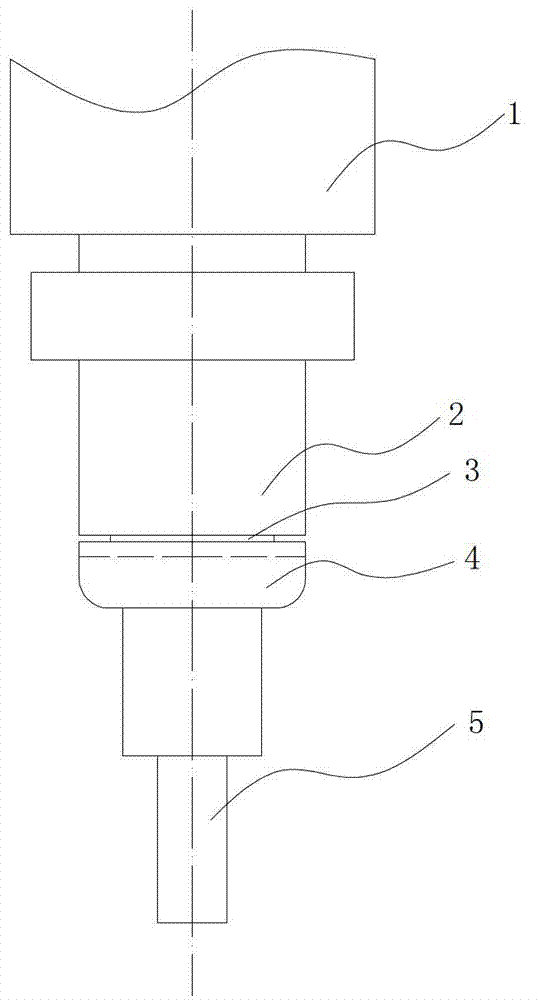

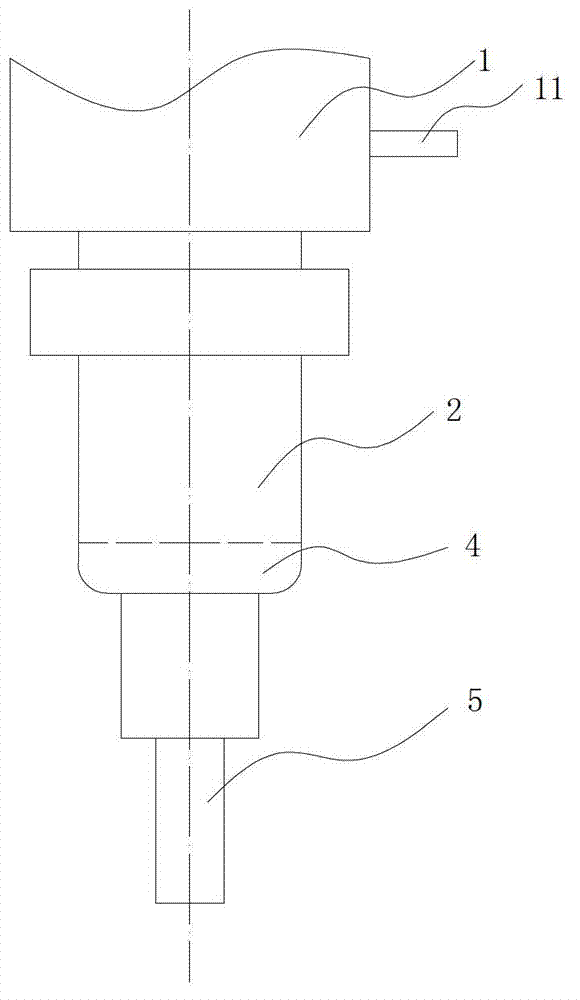

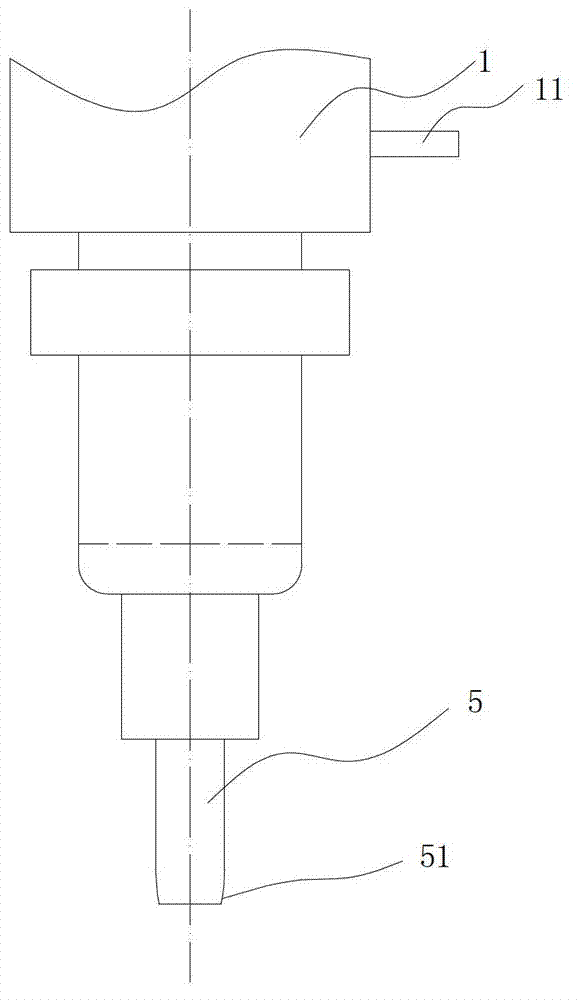

[0030] The present invention as figure 1 , 2 As shown: the CNC turret punch press includes hydraulic drive cylinder 1, punch 2, striking head 4, upper die 5, lower die and controller, and also includes interconnected punching force tracking collector, punching force signal acquisition and conditioning A circuit and a control circuit, the control circuit is connected to the controller; the stamping force tracking collector is arranged at a force transmission position above the upper die 5 .

[0031] The first embodiment of the present invention is as figure 1 As shown, the punching force tracking collector is a force sensor 3, and the force sensor 3 is arranged between the punch 2 and the striking head 4, and collects the axial force that the punching force reacts on the striking head. The force sensor 3 is connected to the control circuit. The load cell 3 can choose dynamic pressure sensors with different signals according to the requirements of different tonnages.

[0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com