Belt conveyer dedicated to turret punch press

A technology of belt conveyors and turret punching machines, which is applied to conveyors, conveyor objects, transportation and packaging, etc. It can solve problems such as inconvenient operation for operators, difficult to clean up waste materials, and potential safety hazards, and achieve work reliability and Good sealing, long service life and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

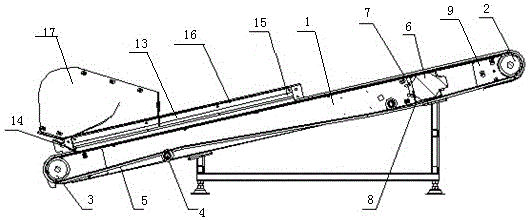

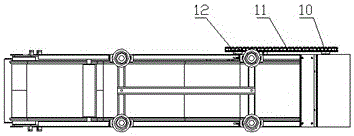

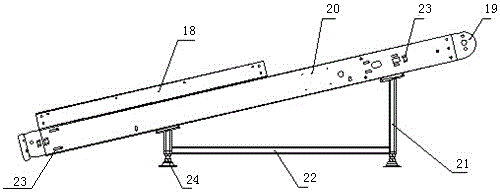

[0016] In order to make those skilled in the art better understand the technical solution of the present invention, the following in conjunction with the attached Figure 1-4 The present invention is further analyzed.

[0017] Such as Figure 1-2 As shown, a special belt conveyor for turret punch presses, including body 1, driving roller group 2, driven roller 3, idler roller 4, conveyor belt 5, motor 6, motor connecting plate 7, motor backing plate 8, motor Cover 9, sprocket 10, chain 11, sleeve 12, rubber 13, hair brush 14, guide plate 15, bead 16 and machine tool docking sheet metal group 17; The head of the body 1, the motor 6 drives the chain 11 to circulate through the sprocket 10; the sleeve 12 is installed on the motor shaft to act as an axial fixation, thereby driving the driving roller group 2 to run, and the driving roller group 2 and the driven roller 3 pass through the bolts The connection is respectively installed on the head and tail of the machine body 1. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com