High-precision stamping mould

A stamping die, high-precision technology, applied in the field of tooling and fixtures, can solve the problems of unsatisfactory cooperation accuracy of airport sliders, limit the use efficiency of ordinary punching machines, and the normal use of molds, etc., to achieve reduced processing costs, reasonable structure, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

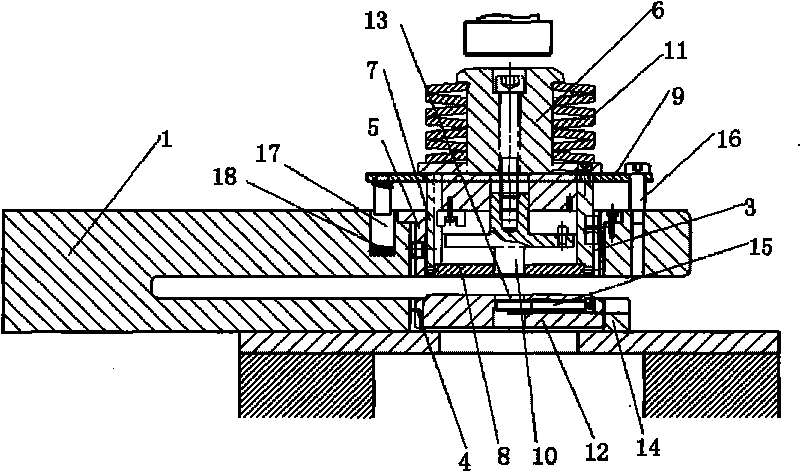

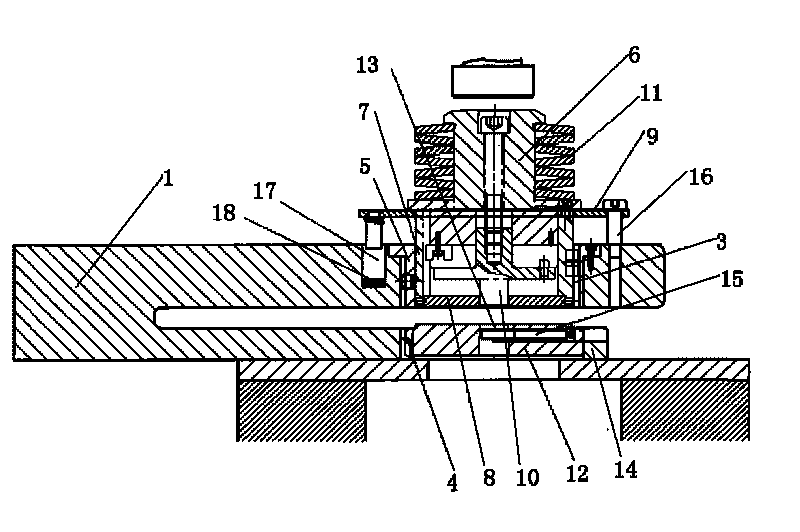

[0011] Referring to the accompanying drawings, the high-precision stamping die includes a mold frame body 1, a lateral blind feeding groove 2 is opened on one side of the mold frame body 1, an upper mold installation hole 3 is opened above the blind feeding groove 2, and a lower mold mounting hole is opened below the blind feeding groove 2. Die mounting hole 4, upper die mounting hole 3 is equipped with a guide die set 5, a pressing device is slidably installed in the guide die set 5, and the pressing device includes a sliding sleeve 7 and a pressing plate 8 at the lower end of the sliding sleeve. The upper end of 7 is equipped with upper formwork 9, is provided with punch 10 in the sliding sleeve, the lower end of punch passes through binder plate 8, the upper end passes through upper formwork and strike column 6 is installed, the top of strike column 6 has steps, strikes A compression spring 11 is set on the column 6, and the lower end of the compression spring is placed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com