Unilateral automatic charging/discharging device

An automatic loading and unloading, unilateral technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of high labor intensity of workers, large equipment occupied space, increased enterprise cost, etc., and achieves ingenious structural design and universal type. Strong, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

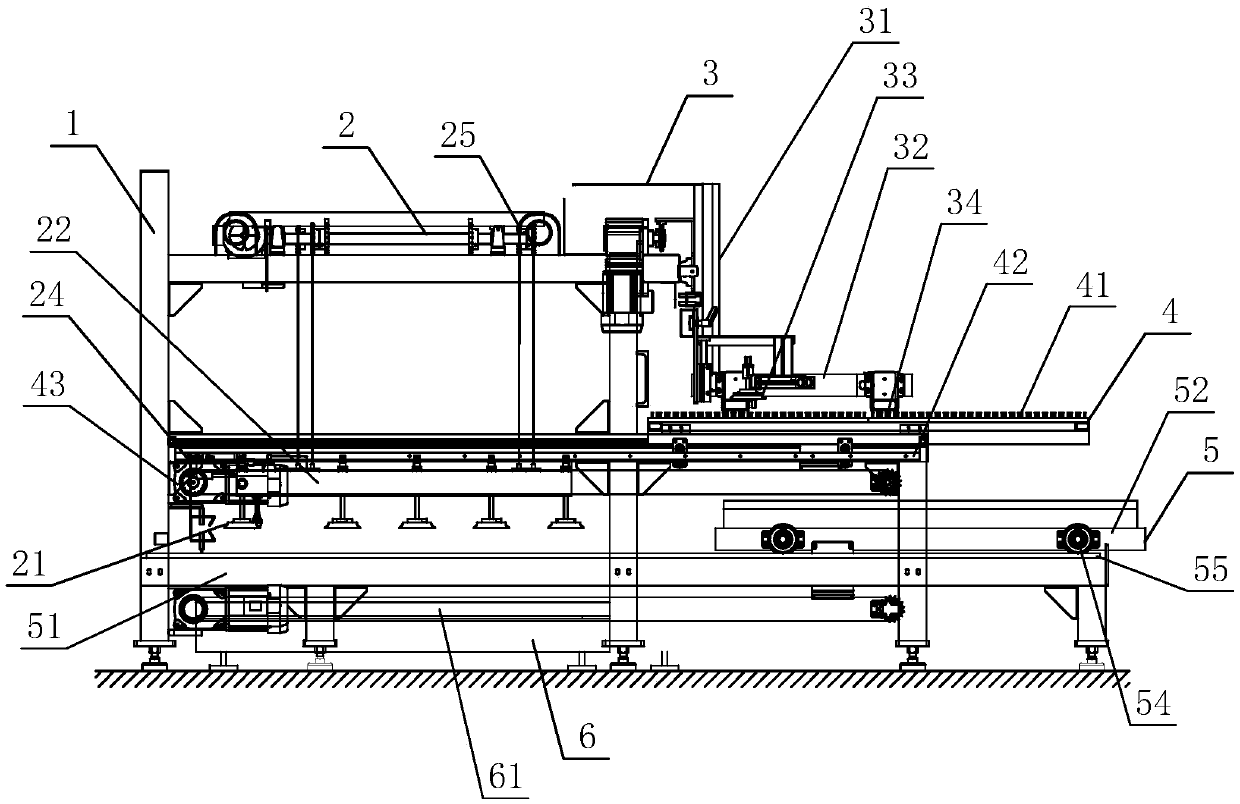

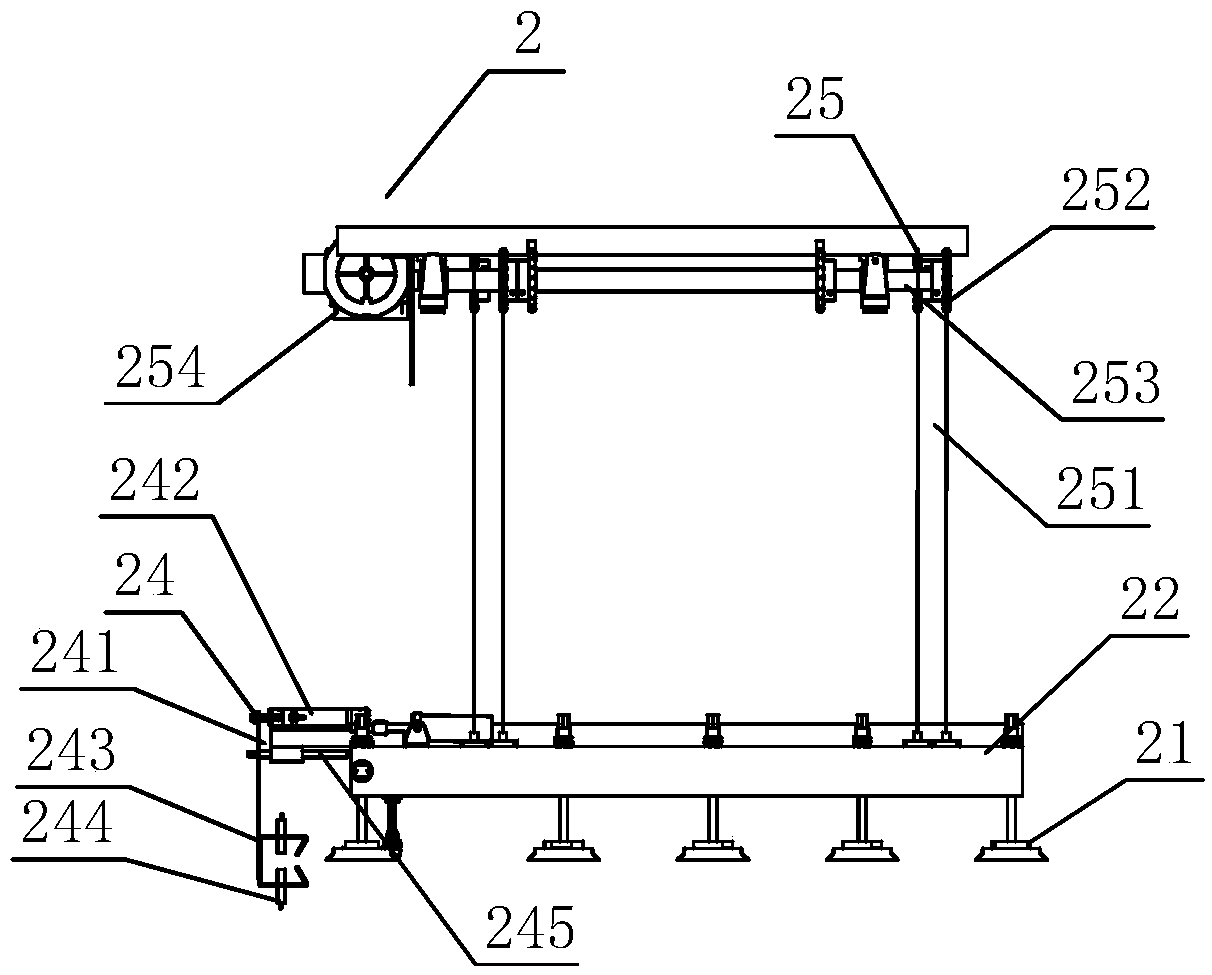

[0037] Such as Figures 1 to 8 As shown, a kind of unilateral automatic loading and unloading device of the present invention comprises a frame 1, wherein: along the upper part of the frame 1, a single suction cup extraction part 2 that can be lifted and picked up is provided, and the middle part has a movable working part that can move horizontally. The table part 4 and the lower part are provided with a movable material warehouse part 5 which can move horizontally, and the movable workbench part 4 and the movable material warehouse part 5 can move horizontally relative to the single sucker extraction part 2. The table part 4 moves horizontally relative to the feeding part 3 with clamps.

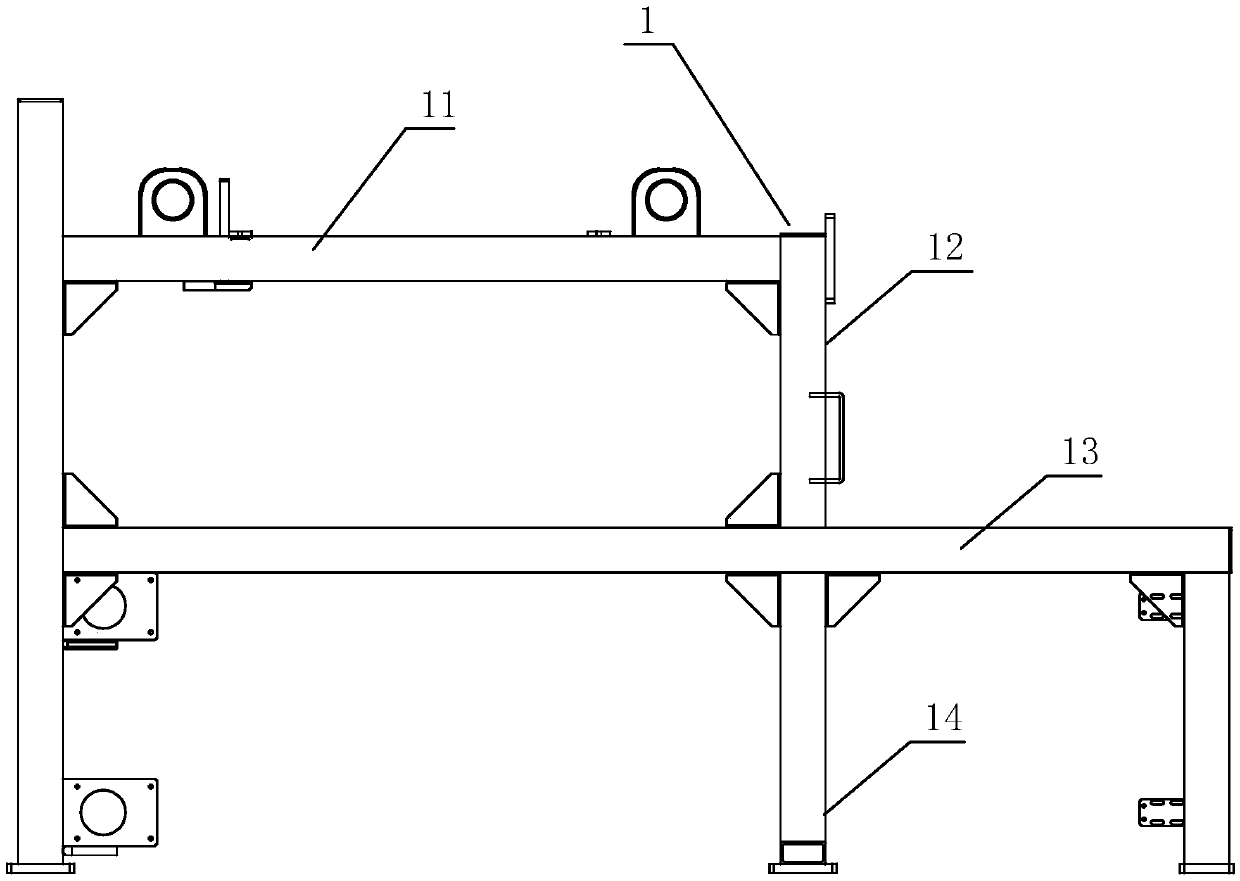

[0038] The frame 1 is provided with a suction cup extraction device installation surface 11, a mobile clamp feeding part installation surface 12, a mobile workbench moving guide rail installation surface 13 and a mobile material warehouse support installation surface 14, which are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com