Self-positioning fixture

A self-positioning and fixture technology, applied in positioning devices, clamping, manufacturing tools, etc., can solve the problems of reducing processing efficiency, time-consuming, processing deviation, etc., and achieve the effect of improving precision and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

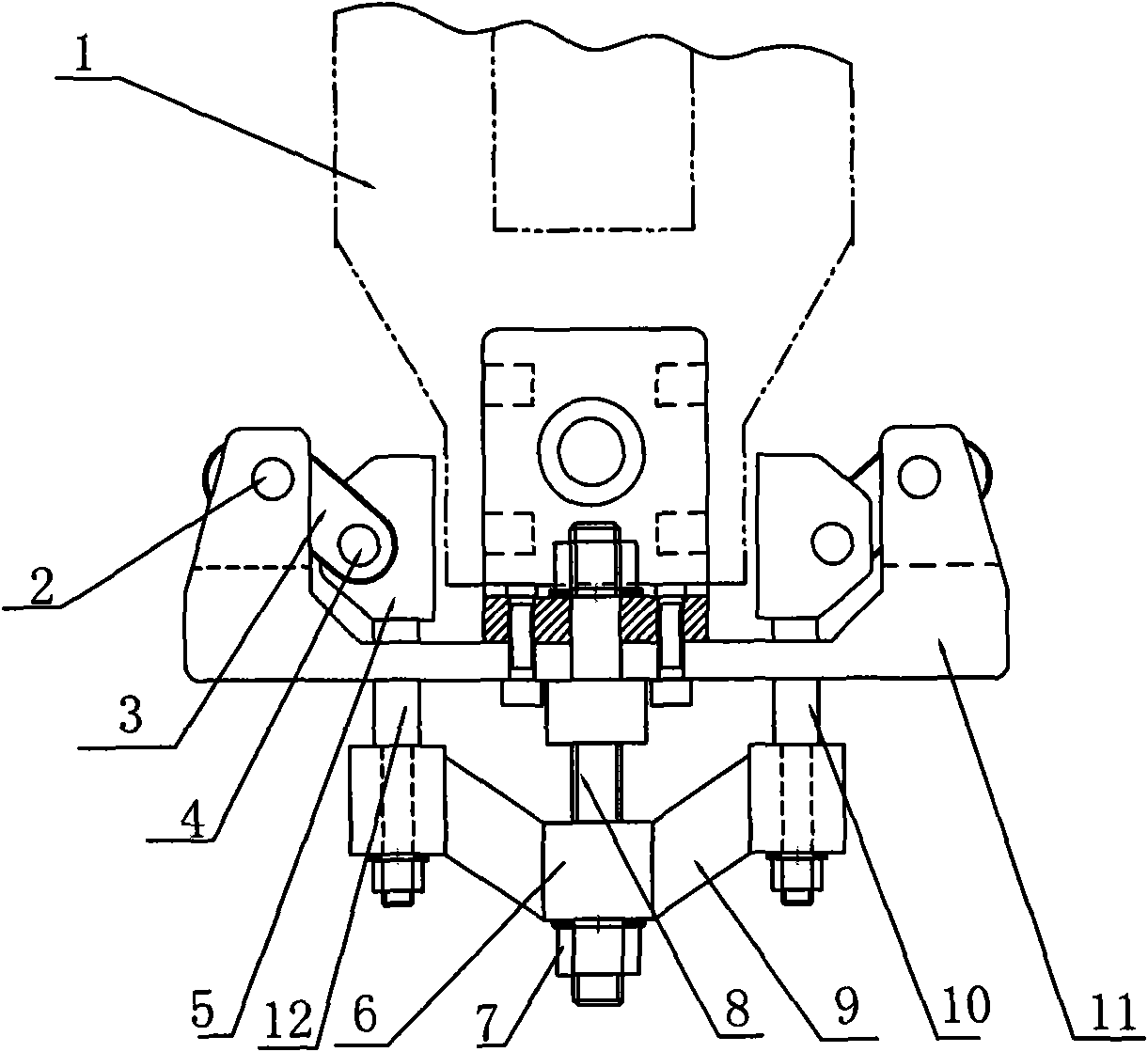

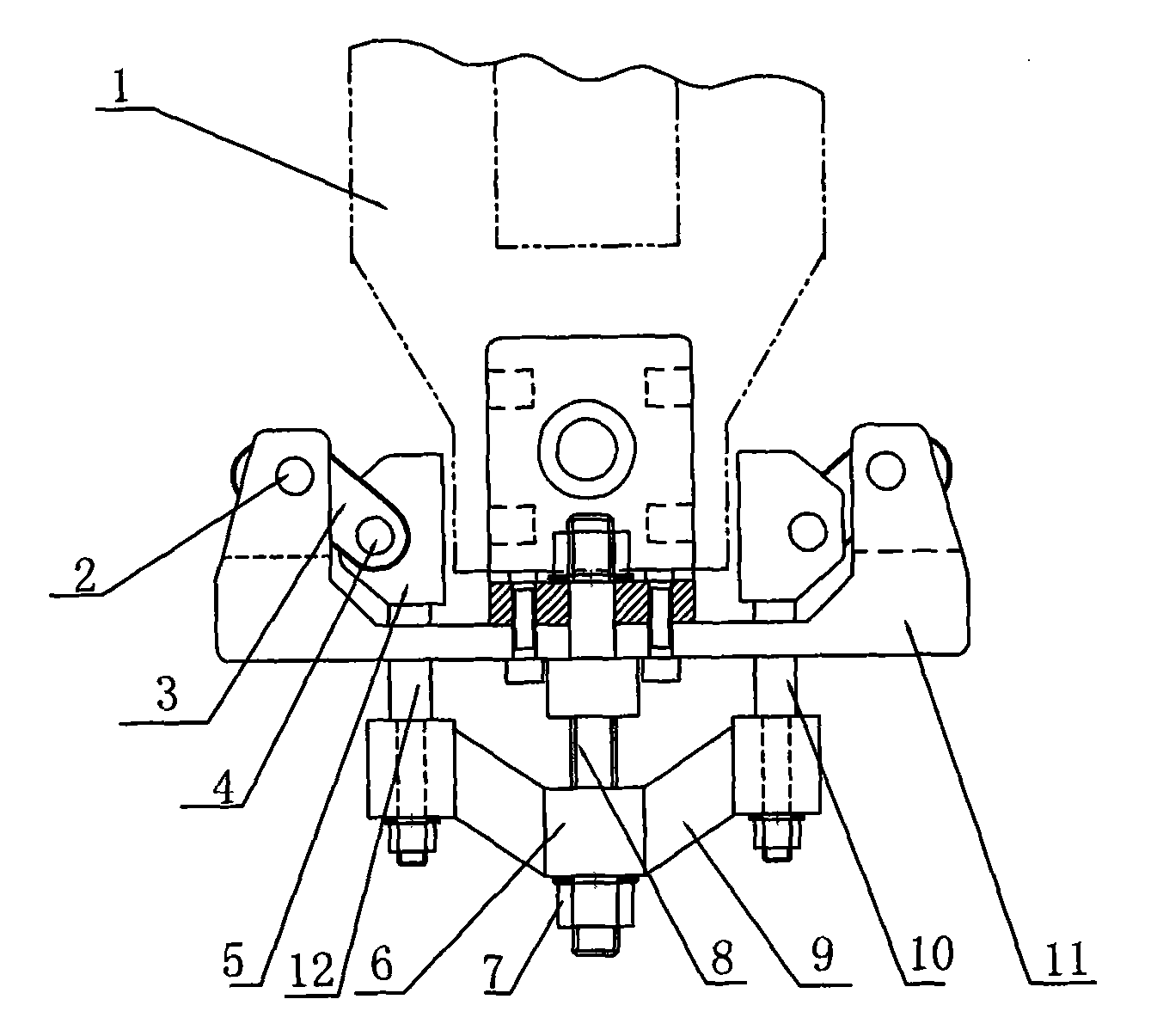

[0009] A self-positioning fixture of the present invention, such as figure 1 As shown, it includes a U-shaped mount body 11, a lifting device and a clamping device.

[0010] The lifting device includes a screw rod 8, a nut 7 adapted to the screw rod 8 and connected to the screw rod 8, a left push rod 12, a right push rod 10 and a push rod seat. The rod seat is symmetrically connected with two horizontal bars 9 on both sides of the bushing 6, the bushing 6 is set on the screw 8, and the nut 7 is connected to the screw at the bottom of the bushing 6; hole, two push rods are located in the through hole, and can slide up and down, left and right along the through hole, and two cross bars 9 are connected with the lower ends of the two push rods respectively, so that the rise of the push rod seat drives the rise of the two push rods.

[0011] The clamping device includes two clamping blocks 5 and two rotating levers 3, and the two clamping blocks 5 are fixedly connected to the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com