Main transmission system of full electric servo ball screw type numerical control rotating tower punch

A technology of CNC turret punch press and main transmission system, applied in the field of main transmission system, can solve the problems of affecting the precise positioning of the hole point under the slide block of the punching machine, complex mechanism, reducing mechanical efficiency, etc. High precision, reduced thrust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

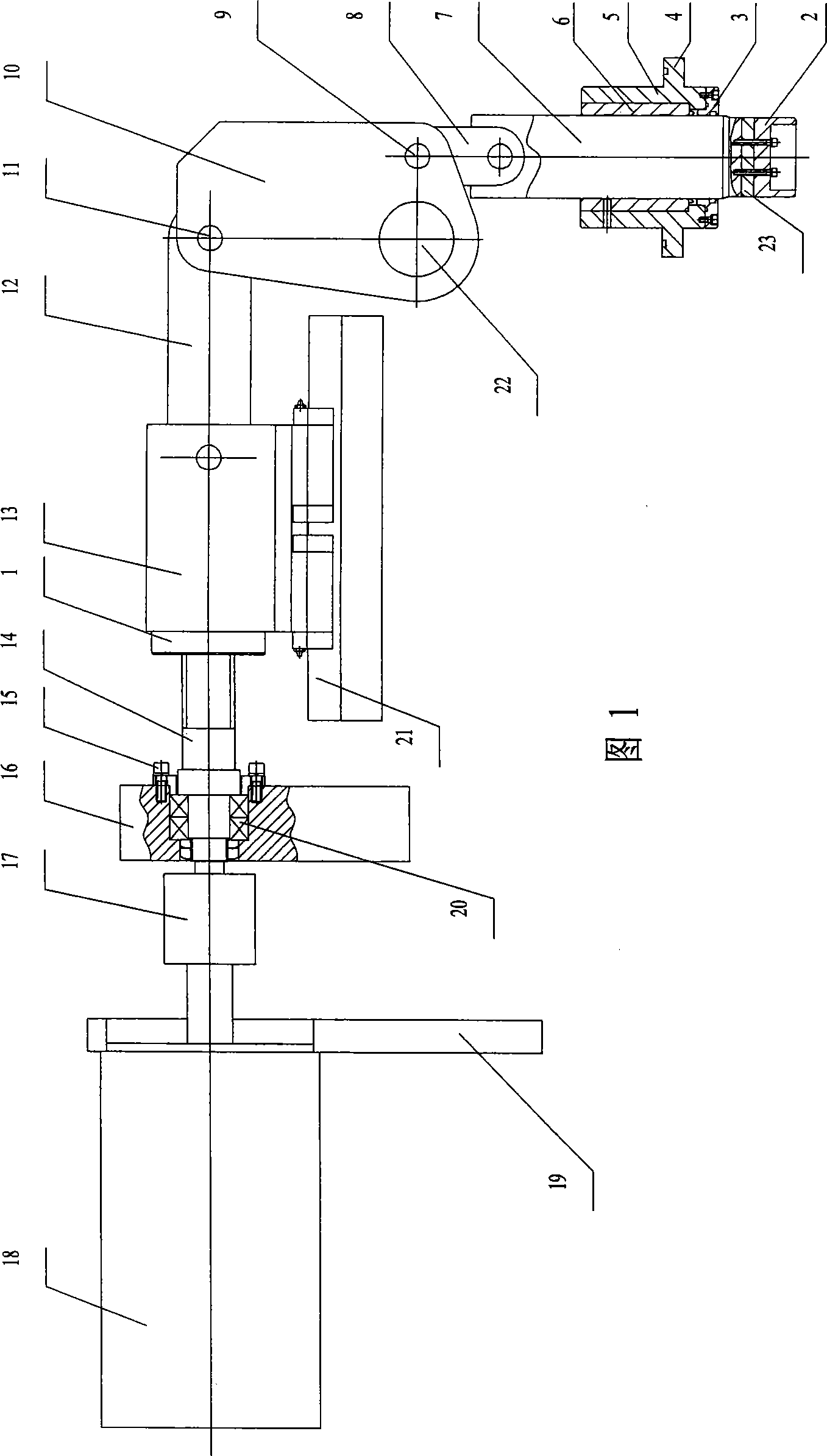

[0009] In the figure: 1. Nut, hinged with ball screw 14; 2. Hitting head, used to hit the mould; 3. Gland, with sealing ring sealing grease inside; 4. Flange, used to install guide sleeve 5; 5: The guide sleeve guides the slider 7 to produce up and down linear motion; 6. The slider, the slider 7 moves up and down along the copper sliding sleeve 6 without roughening and protects the slider 7; 7. The slider , move up and down linearly in the copper sleeve 6; 8, the short connecting rod, connect the booster block 10 and the slider 7; 9, the pin, connect the booster block 10 and the short connecting rod 8; 10, the booster block, start Leverage, to amplify the thrust of the long connecting rod 12; 11, the pin shaft, connect the booster block 10 and the long connecting rod 12; 12, the long connecting rod, used to connect the nut connecting block 13 and the booster block 10; 13, the nut Connecting block, used to connect guide rail 21 and long connecting rod 12; 14, ball screw, conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com