Grinding control system and control method for blade milling machine

A technology of sharpening machine and numerical control system, which is applied in the direction of grinding automatic control device, grinding machine parts, grinding machine, etc., can solve the problems of poor human-computer interaction, solidification of sharpening process, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with specific embodiments:

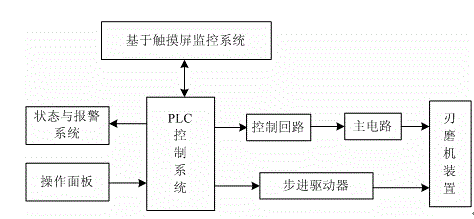

[0035] Such as figure 1 - Image 6 As shown, the CNC system of sharpening machine includes sharpening machine device, main circuit, control loop, PLC control system, stepper motor driver, monitoring system based on touch screen, control panel, operating status and alarm system;

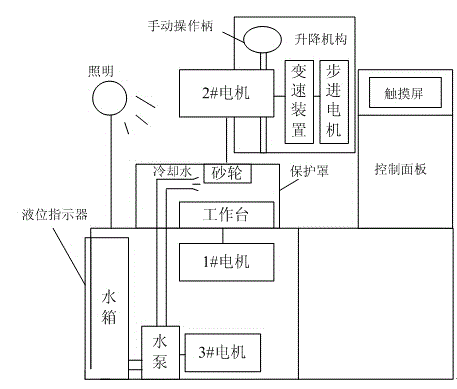

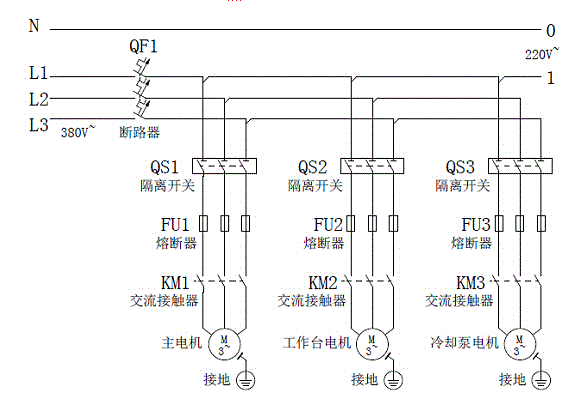

[0036] The sharpening machine device consists of a cabinet, a water tank with a liquid level indicator installed in the cabinet, a water pump connected to the water tank, a water pump drive motor, namely 3# motor, and a workbench drive motor, namely 1# motor, which are set on the cabinet. The workbench, the lifting mechanism, the main motor connected to the grinding wheel with the output shaft installed on the lifting mechanism, namely the 2# motor, the grinding wheel driven by the main motor suspended above the workbench, and the protective cover covering the grinding wheel and the workbench , A con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com