Optimization method of blending rate of coal for coking based on modified differential evolution algorithm

An evolutionary algorithm and improved differential technology, applied in coking ovens, calculations, special data processing applications, etc., can solve problems such as small-scale optimization problems, and achieve the effects of accelerating convergence speed, improving search efficiency, and improving solution quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

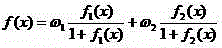

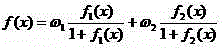

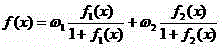

[0028] There are four types of coal in the coking plant: fat coal, coking coal, lean coal and 1 / 3 coking coal. Among them, the available fat coals are: Malan, Zhenchengdi, Xinzhi, and Guangyuan. The coal blending ratios are expressed as: x 1 , x 2 , x 3 , x 4 , the prices (yuan / ton) are: 1324.79, 1324.77, 1305.28, 1249.54 respectively; available coking coals include: Tunlan, Huajin, Liukuang, and medium ash, and their coal blending ratios are expressed as: x 5 , x 6 , x 7 , x 8 , and their prices (yuan / ton) are: 1408.45, 1384.24, 1291.34, 1240.25; available lean coals are: Dongqu, Wuyang, and their coal blending ratios are expressed as: x 9 , x 10 , the prices (yuan / ton) are: 1064.66, 1082.31 respectively; available 1 / 3 coking coal is: Zhaocheng, and its coal blending ratio is expressed as: x 11 , the price (yuan / ton) is 1147.3, then the coal blending cost can be expressed as: (c i Indicates the cost of a single type of coal) (1)

[0029] The sum of the single coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com