High-speed feeding mechanism

A feeding mechanism and high-speed technology, applied in the field of presses, can solve problems such as low speed, resonance, and poor rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

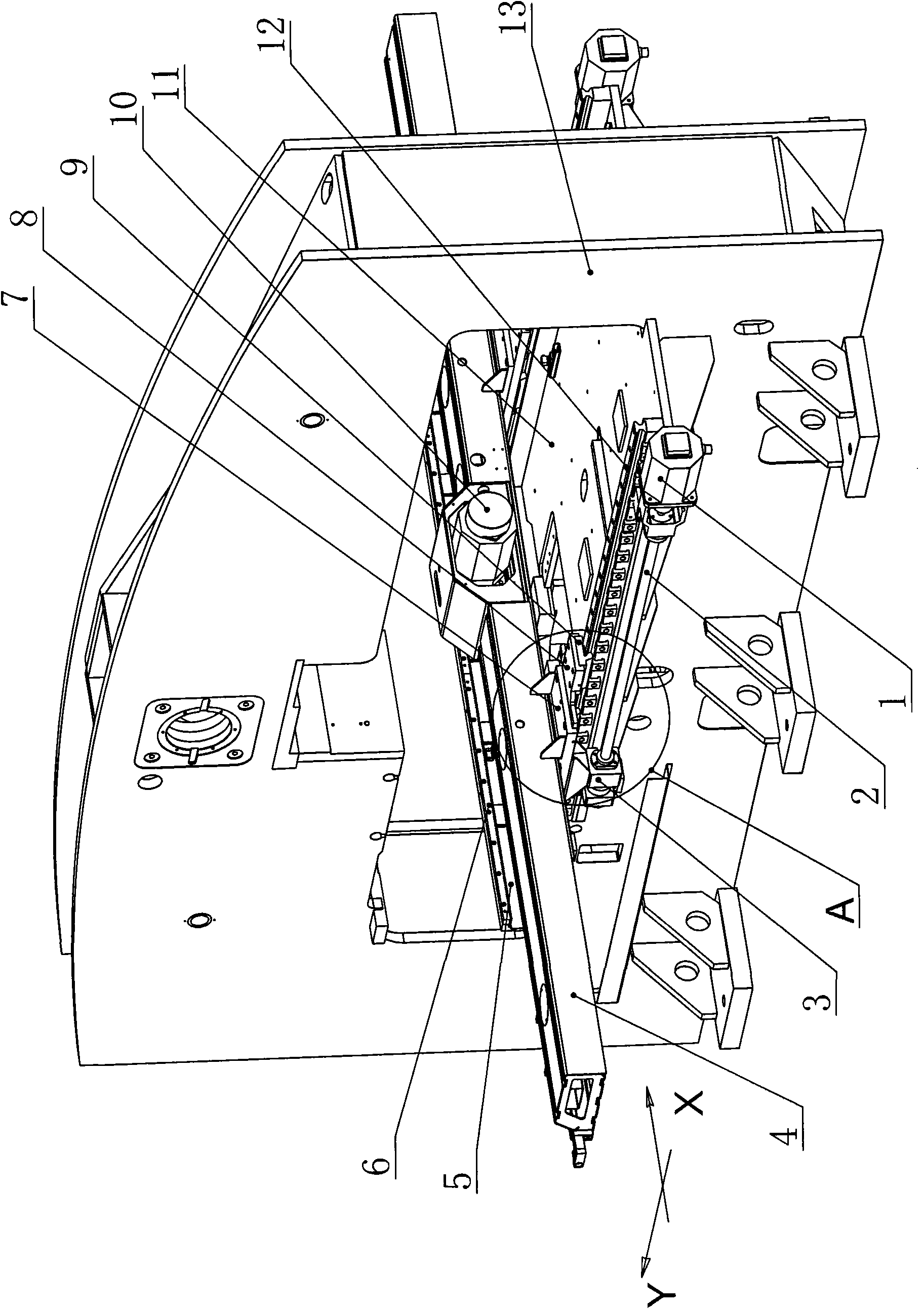

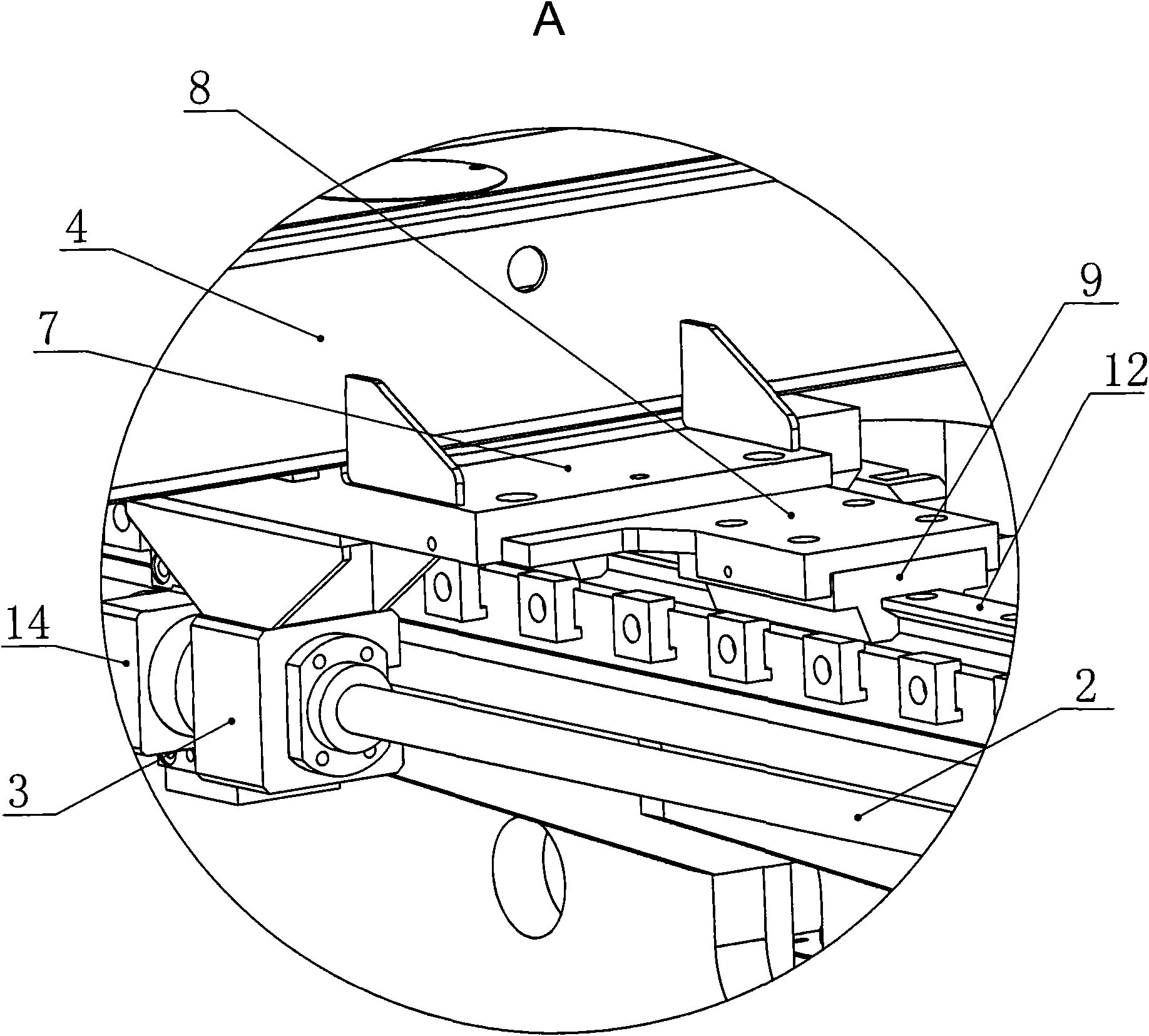

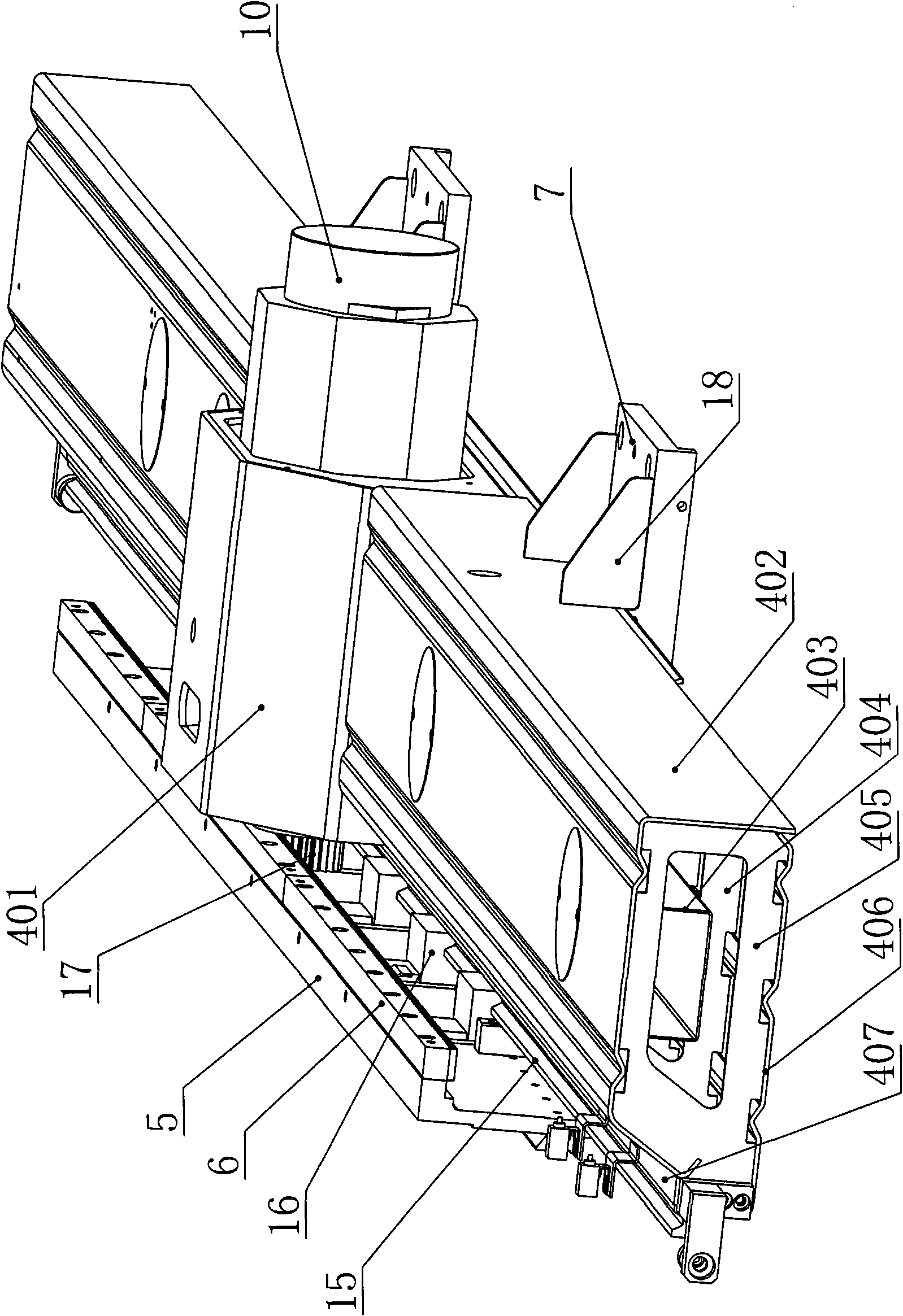

[0020] Such as Figure 1-4 Shown is a high-speed feeding mechanism, including a feeding table 11 set on the frame, the feeding table 11 is provided with a Y-axis drive mechanism, the upper side of the Y-axis drive mechanism is connected with a beam 4, and the beam 4 is connected with X Shaft driving mechanism, the longitudinal direction of the beam 4 is perpendicular to the Y axis and parallel to the X axis.

[0021] The structure of the Y-axis drive mechanism: It includes two Y-axis linear guides 12 arranged in parallel on the front and rear sides of the feeding table 11. The Y-axis linear guide 12 is matched with a Y-axis slider 9, and the Y-axis slider 9 is connected with Connecting plate 8; the bottom of the cross beam 4 is connected and fixed with the two connecting plates 8 by the reinforcing plate 7. The front and rear sides of the reinforcing plate 7 are provided with reinforcing ribs 18 connected to the cross beam 4; the front and rear edges of the feeding table 11 are r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com