Multi-mold interchangeable indexing station and CNC turret punch die system

A numerical control turret punching machine and mold technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as the inability to realize multi-sub-mold indexing stamping, increase the weight of parts in the rotating part, and the complex structure of the mold rotating device. , to achieve the effect of enriching the functions of the punching machine, occupying a small space, and increasing the number of molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

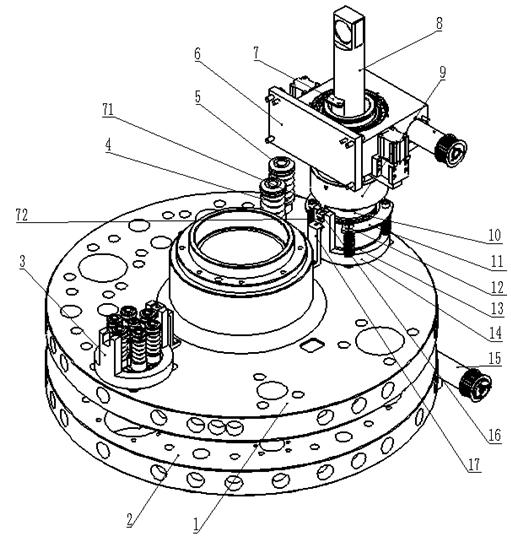

[0039] Example 1: A multiple mold interchangeable indexing station

[0040] Such as figure 2 As shown, a multiple mold interchangeable indexing station, which includes a turntable with at least one indexing mold position, the turntable includes an upper turntable 1 and a lower turntable 2, and also includes a worm gear installed above the working position of the turntable. The turbine shaft 9 that is connected with the turbine 27 in the mold rotary device casing.

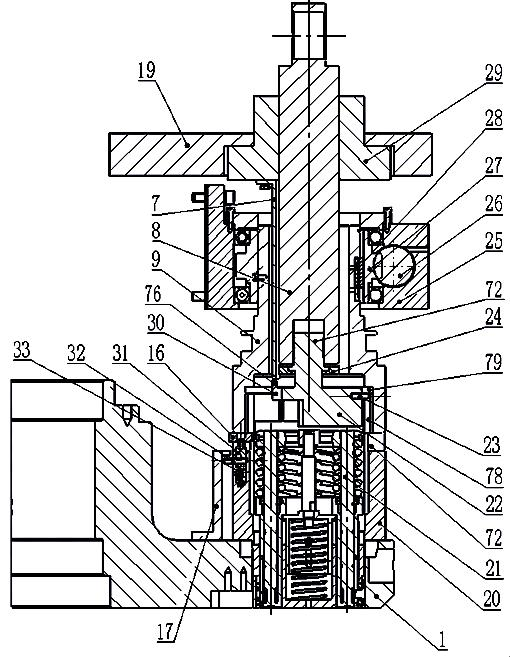

[0041] Such as image 3 with 4 As shown, the turbine shaft 9 is set outside the striking rod 8 connected with the bed fixed plate 19; and two symmetrical bosses 71 are arranged at the bottom of the turbine shaft 9, and the rotary upper die base 14 or The multi-sub-mold base 20 is provided with a groove 72 that is precisely matched with the boss 71 on the top of the rotary upper mold base 14 or the periphery of the multi-sub-mold base 20, and a positioning mechanism is provided at the bottom of the groove 72 on o...

Embodiment 2

[0054] The similarities between this embodiment and Embodiment 1 will not be described again. The difference is that it is a numerically controlled turret punching die system, which is provided with multiple mold interchangeable indexing stations as described in Embodiment 1.

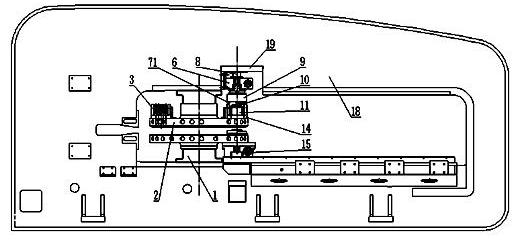

[0055] see figure 1 , figure 2 A multi-mold interchangeable indexing station and CNC turret punch press mold system includes an upper turntable 1 and a lower turntable 2 arranged on a bed. It also includes the upper and lower mold rotary devices 6 and 15 driven by the worm mechanism connected to the upper (lower) side of the turntable working position and the bed; the striking rod 8 connected with the power system, etc.

[0056] see image 3 , Figure 6 , The guide sleeve 29 is arranged in the fixed plate 19 on the bed 18, and forms a sliding pair with the striking rod 8. The turbine shaft 9 is set on the turbine shaft 27 of the mold rotary device, and is connected with the turbine shaft 9 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com