Stamping equipment for guard plate of computer case

A technology of stamping equipment and computer, which is applied in the field of stamping equipment for computer case shields, can solve problems such as large recoil retraction, misalignment of stamping dies and blanks, deformation and distortion of workpieces, etc., to prevent adverse effects, ensure processing efficiency, and process high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

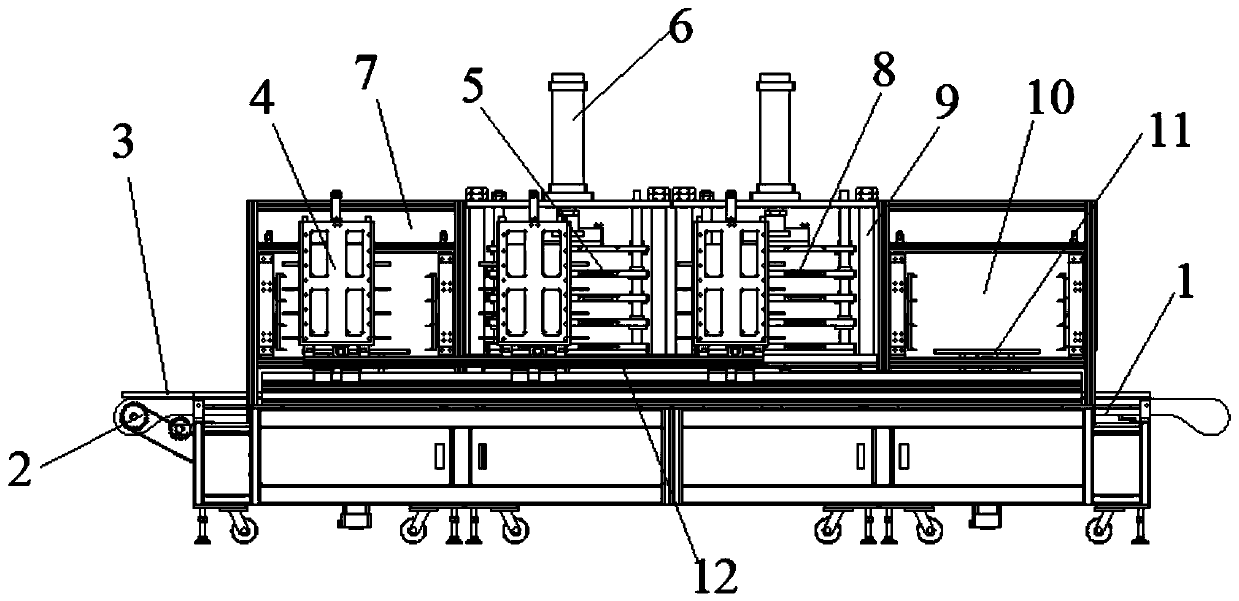

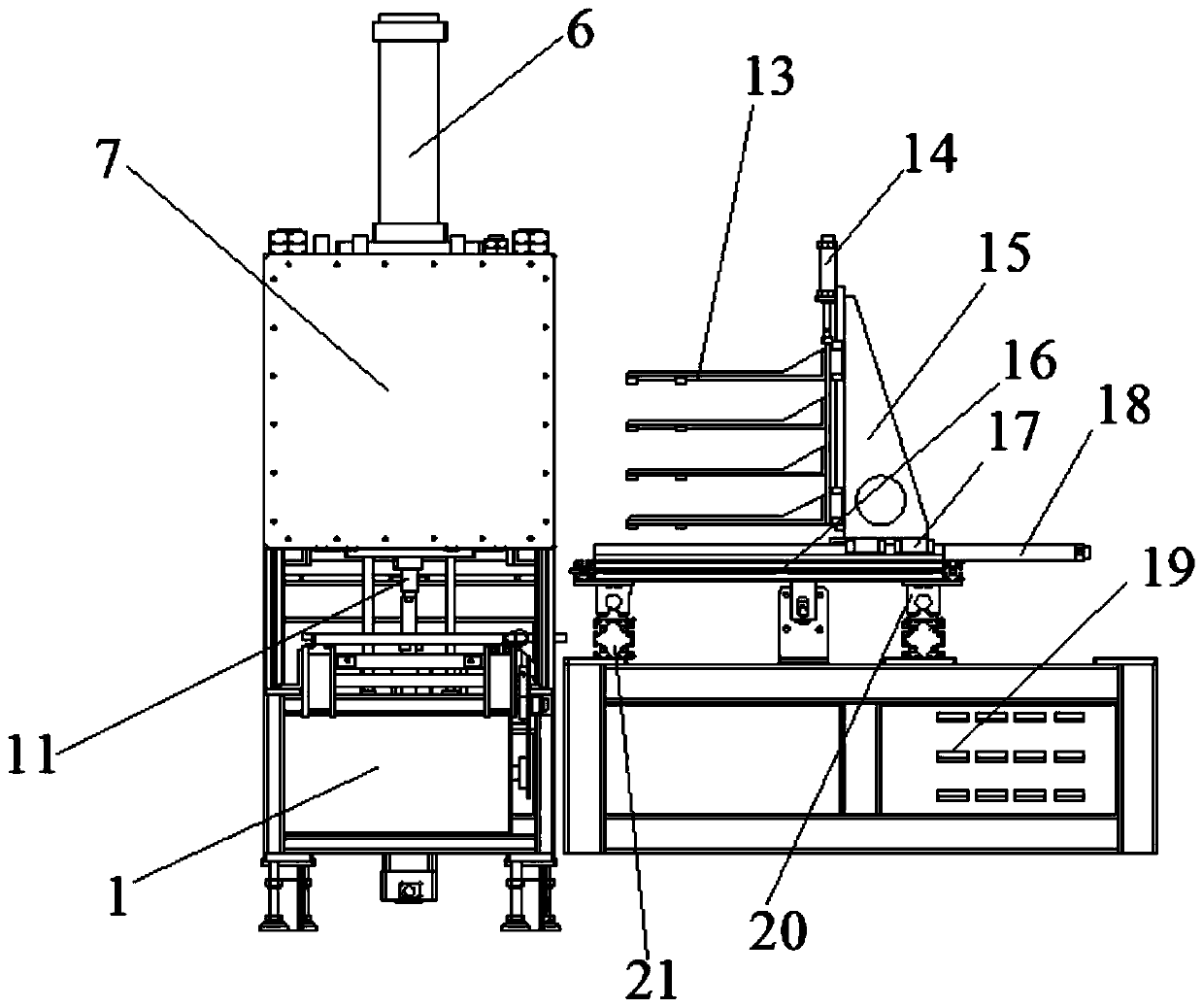

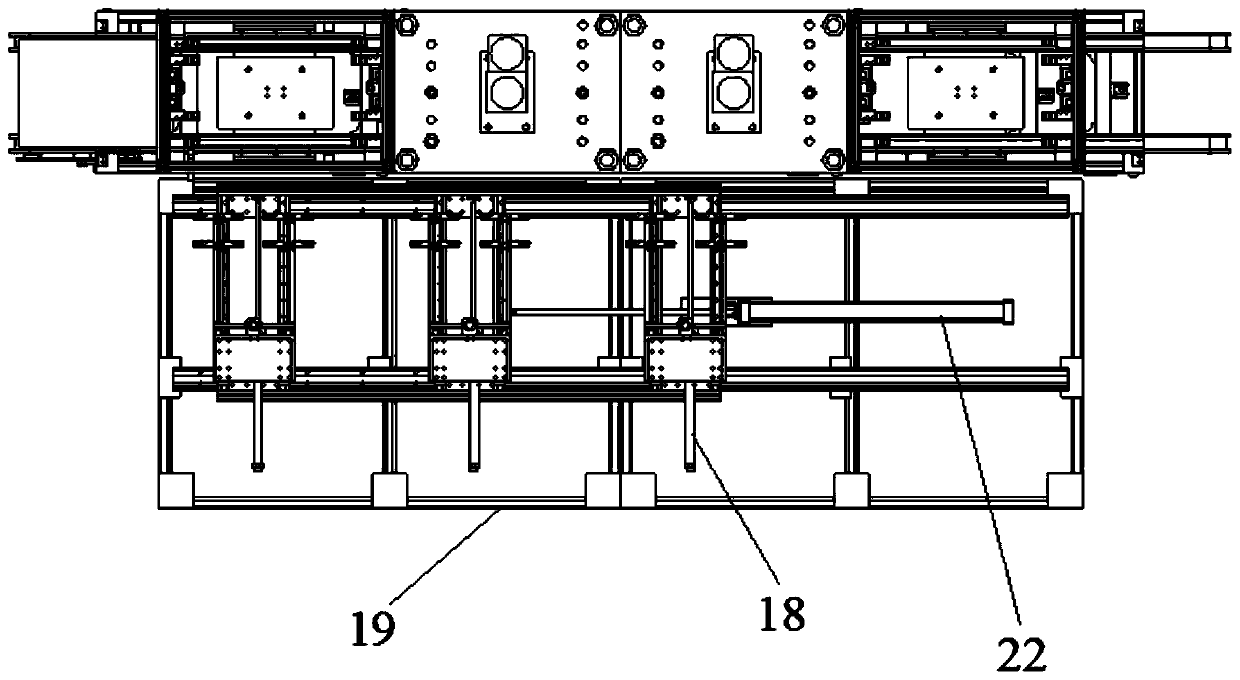

[0023] see Figure 1~5 , in an embodiment of the present invention, a stamping equipment for a computer case shield, which includes a flow-type conveying table 1, a clamping and transferring mechanism 4, a jacking and lifting mechanism, a stamping hydraulic cylinder 6, a hole forming stamping die set 5, Stamping and shaping module 8, loading station 7 and unloading station 10, wherein, along the conveying direction of the flow-through conveyor table, there are successively provided feeding station 7, hole forming stamping station, and stamping and shaping station and the unloading station 10, wherein, the jacking and lifting mechanism located at the center of the width of the flow-through conveying platform is arranged in the loading station and the unloading station, wherein the The hole forming stamping station is provided with a hole forming stamping die set 5, the stamping shaping station is provided with the stamping shaping die set 8, and the hole forming stamping die se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com