Panel stamping and bending process of control cabinet

A technology for stamping and bending and control cabinet, which is applied in the field of sheet metal stamping and bending technology, can solve the problems of high labor intensity of marking operation, difficult calibration of fitters, inconsistent radian and other problems, so as to reduce the marking process and reduce labor intensity. , the effect of saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The stamping and bending process of the control cabinet panel of the present invention includes a blanking process, a notch punching process, a bending process, and a shape correction process;

[0021] The blanking process is as follows: according to the material and thickness of the sheet, adjust the gap between the upper blade and the lower blade of the shearing machine; cut the blank according to the length and width of the designed sheet;

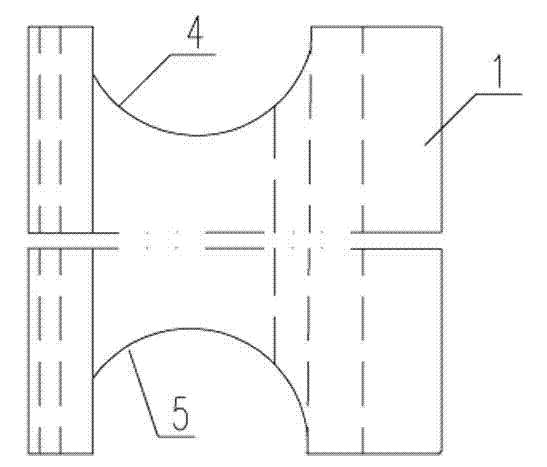

[0022] Notch punching process: use CNC turret punching equipment, program according to the product's appearance development, draw the product appearance development and determine the selected mold; then according to the product design process documents, input the main parameters of the product: plate thickness, Material, length dimension, stamping operation;

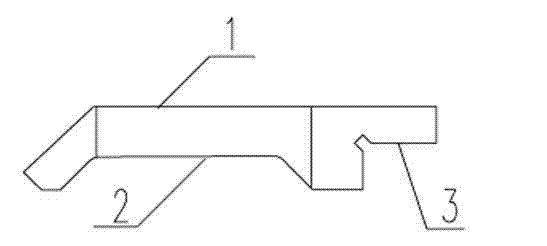

[0023] Bending process: use a bending machine to bend the sheet metal, select the crank arm punch mold, connect the clamping block with the slider, and the slider drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com