Metal plank blanking system and method

A sheet metal, subsystem technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

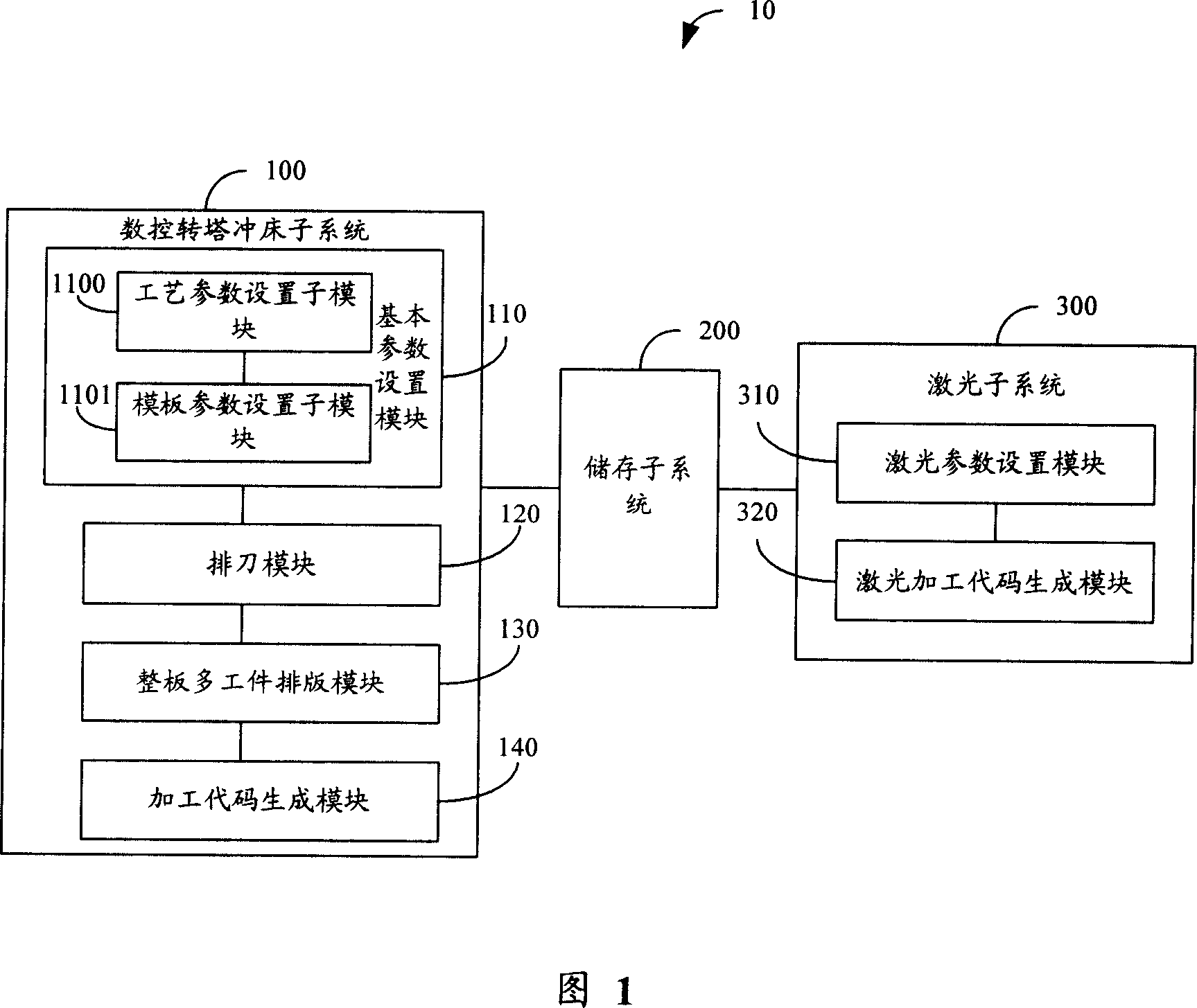

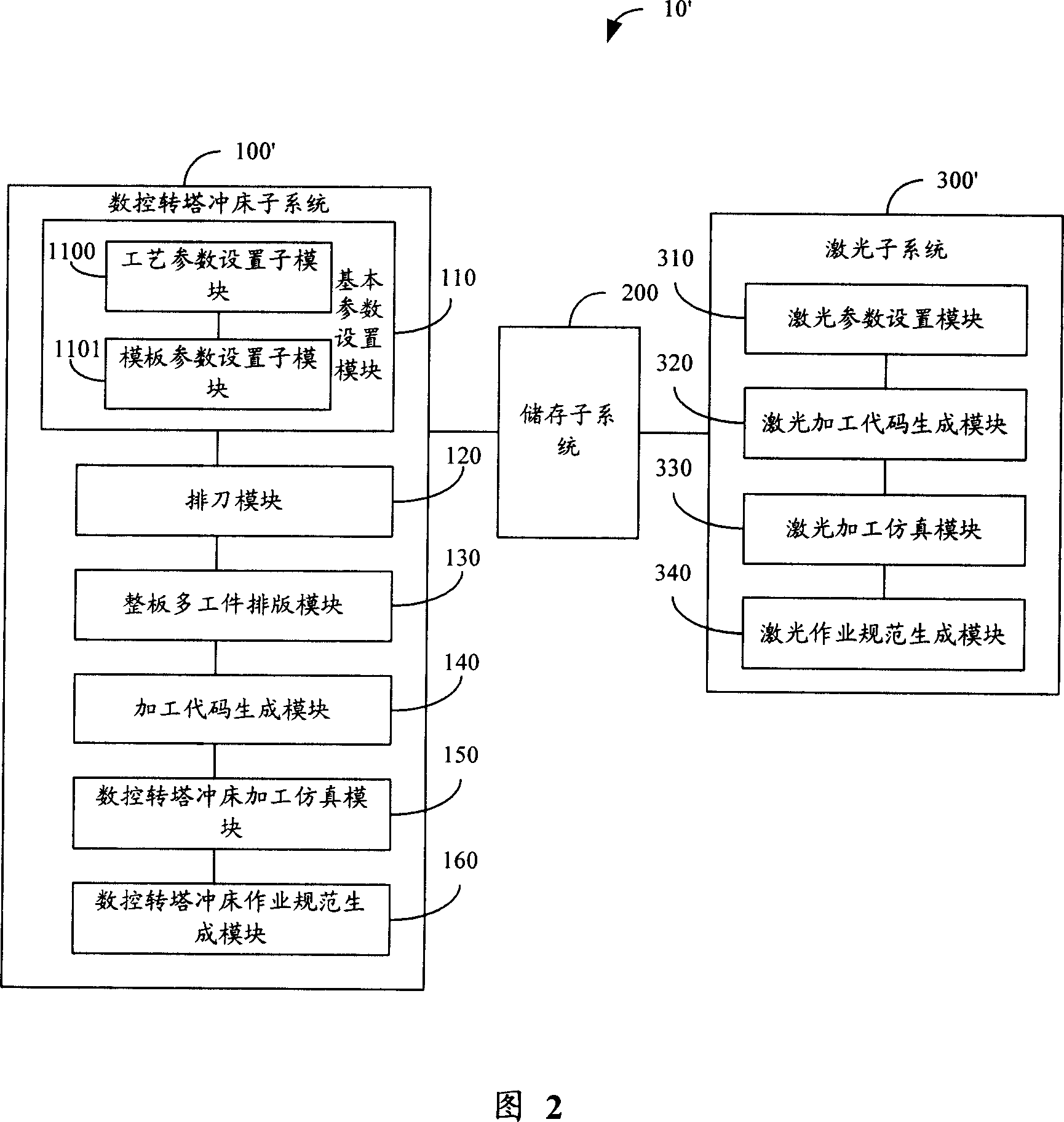

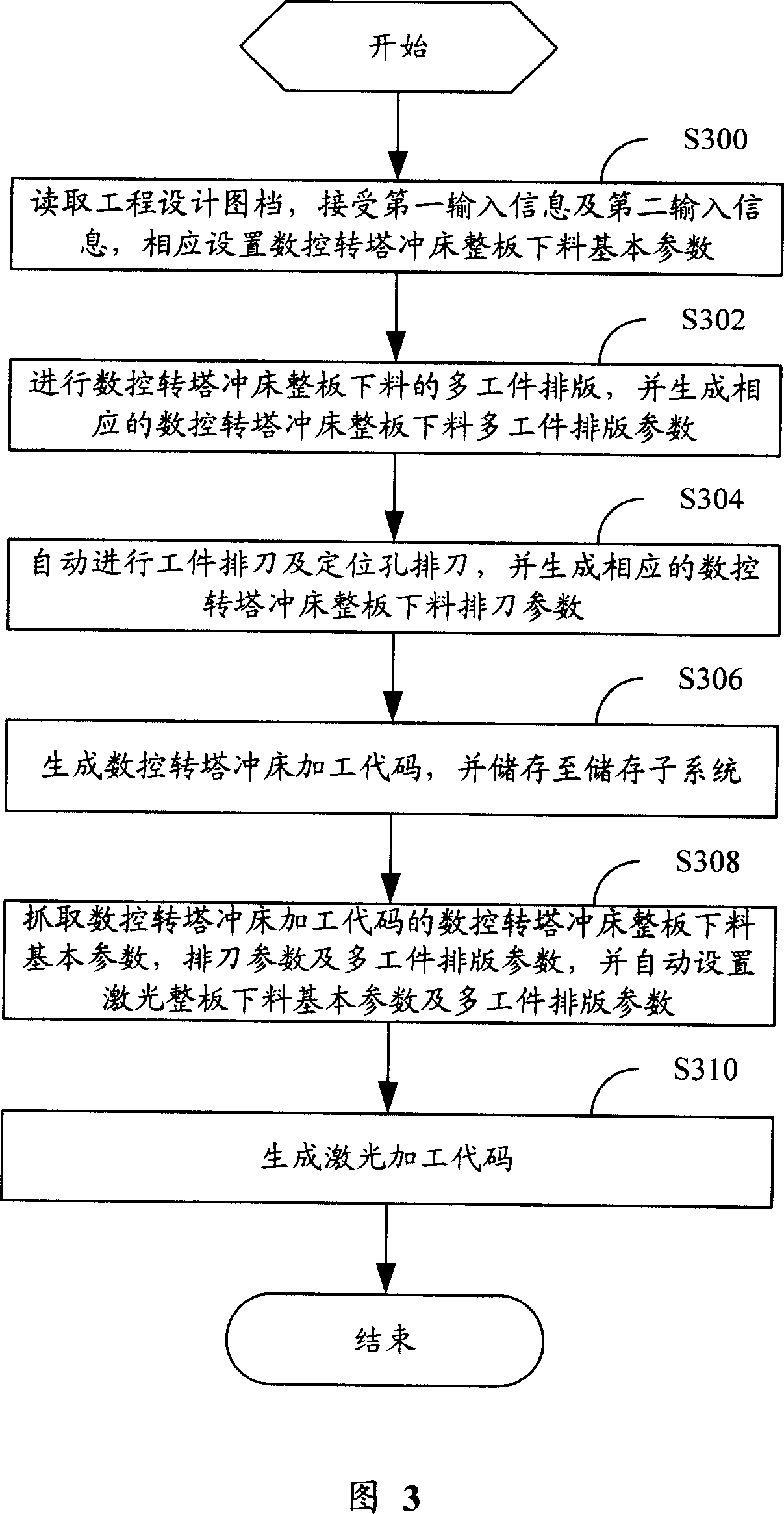

[0015] Please refer to FIG. 1 , which is a block diagram of a whole sheet metal blanking system 10 in an embodiment of the present invention. In this embodiment, the whole sheet metal blanking system 10 integrates the functions of CNC turret punching machine and laser cutting whole plate blanking, and is used to generate CNC turret punching machine processing codes and laser processing codes. The whole sheet metal blanking system 10 includes a CNC turret punch subsystem 100, a storage subsystem 200 and a laser subsystem 300, wherein the CNC turret punch subsystem 100 is used for mold processing, and the laser subsystem 300 is used for laser cutting processing.

[0016] In this embodiment, the CNC turret punch press subsystem 100 is used to read an engineering design drawing file, receive a first input information and a second input information, and set the basic parameters of the CNC turret punch press whole board blanking accordingly, according to The basic parameters of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com