Die replacing device for numerical control turret punch press

A technology of CNC turret punch press and rotary drive device, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of relative motion error and large difference between the turntable and the gripper jaw, and achieve good stability and large stroke range , Efficient grasping or releasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

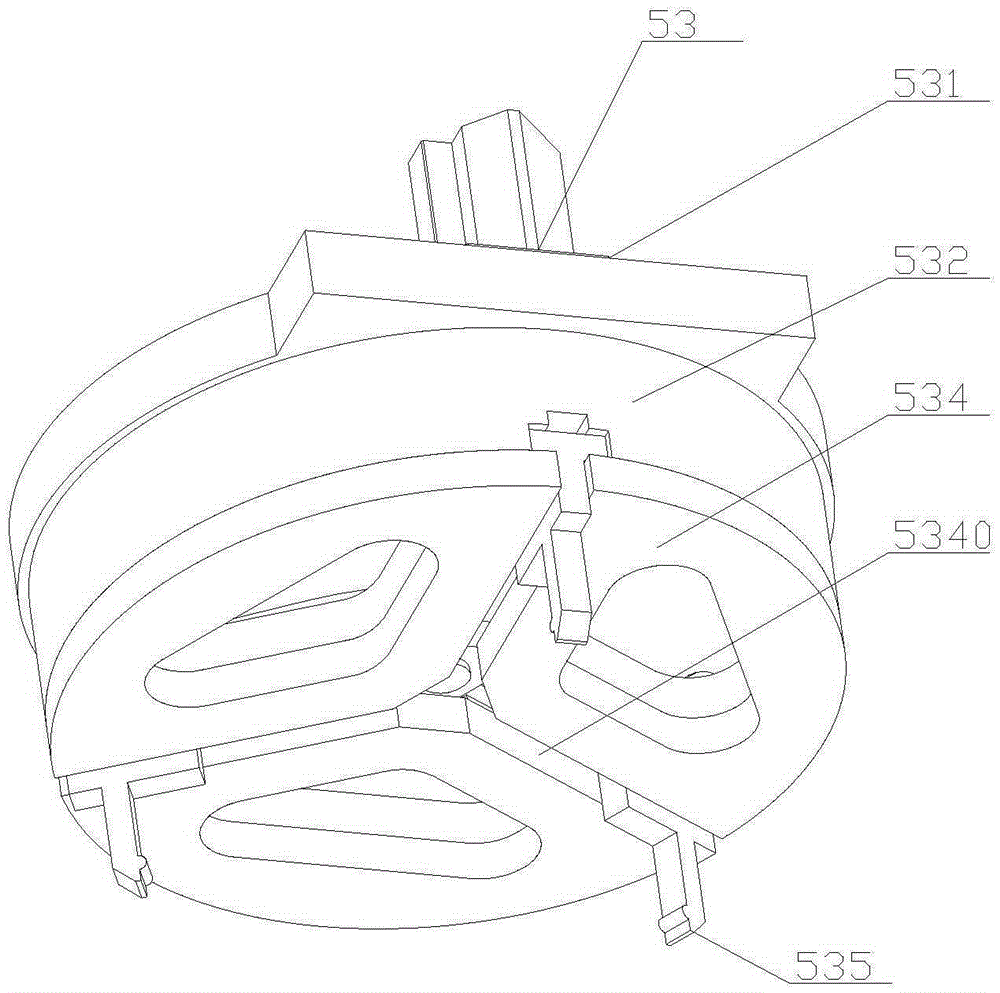

[0037]Embodiment 1: The rotary drive device 536 includes a rotary cylinder 5361 with a power shaft, a pinion gear 5362, a large gear 5363, a limit cylinder 5364 with a drive shaft, and a limit block 5365. The rotary cylinder 5361 is fixedly connected to a fixed On the seat 531, and its power shaft extends into the guide sleeve 532, the pinion 5362 is sleeved on the power shaft of the rotary cylinder 5361, the big gear 5363 is fixedly connected to the cam disc 533, and is connected with the pinion 5362 Mesh with each other, the large gear 5363 and the cam disc 533 are coaxial; in this way, the small gear can be driven by rotating the cylinder, and then the camshaft is driven to rotate through the large gear, thereby finally driving the jaws to perform linear displacement;

[0038] At the same time, because the rotary cylinder runs fast, but its running accuracy is poor, and the running volume is difficult to control, a mechanism for limiting the rotation angle of the cam disc is...

Embodiment 2

[0042] Embodiment 2: the rotary driving device includes a servo motor with an output shaft, a pinion and a bull gear, the servo motor is fixedly connected to the fixed seat, and its output shaft extends into the guide sleeve, and the pinion sleeve Connected to the output shaft of the servo motor, the large gear is fixedly connected to the cam plate and meshed with the pinion, and the large gear and the cam plate are coaxial. Since the servo motor has the characteristics of high running precision and high price, the rotation angle of the cam disc can be precisely controlled by directly sending a signal from the control center during use, that is, the displacement of the gripper jaw can be precisely controlled.

[0043] Let any point on the center line of the camshaft be point i, and the distance between point i and the axis center of the camshaft be R i , at this time, the force direction of the cam groove is the radial direction of the cam disc, and the included angle between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com