Self-suction centrifugal pump with high cavitation resistance

A centrifugal pump and cavitation technology, which is applied to pumps, parts of pumping devices for elastic fluids, and drive pumps, can solve problems such as weakening inlet backflow, and achieve weakening secondary flow vortices, reducing cavitation and Low-frequency pressure pulsation, easy to disassemble and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

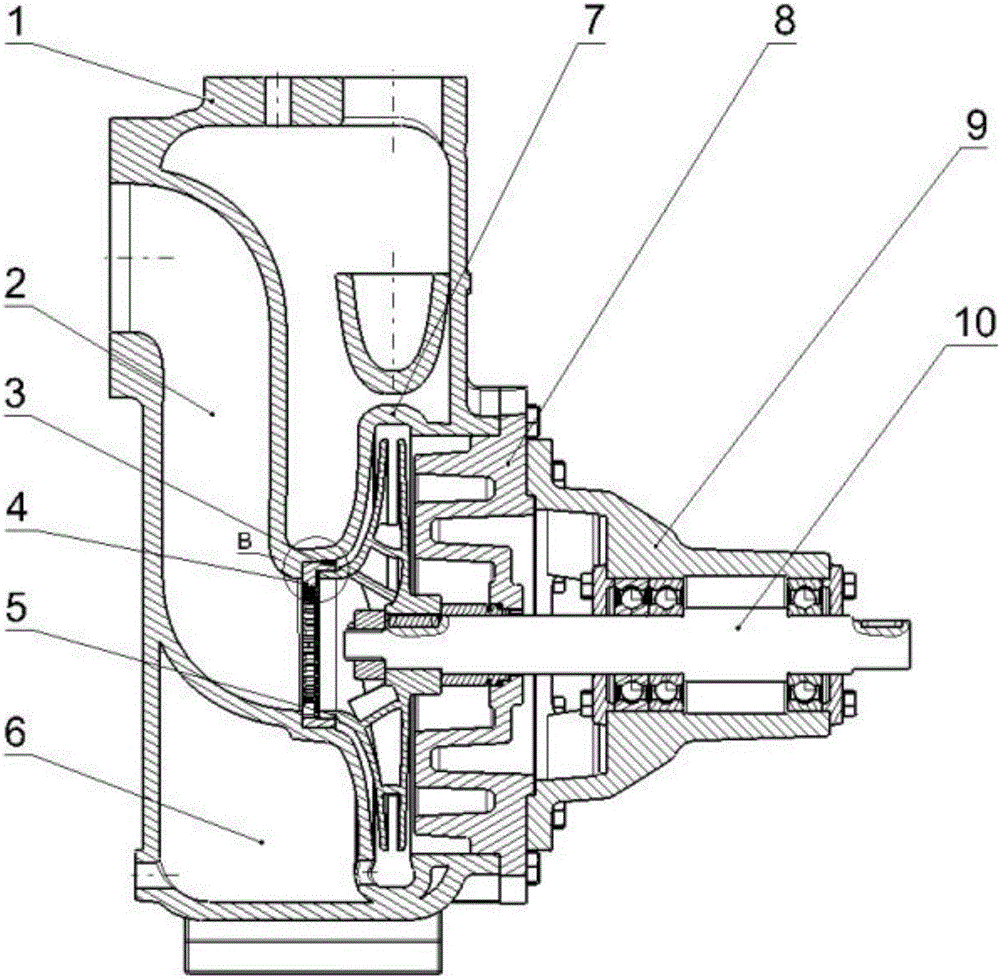

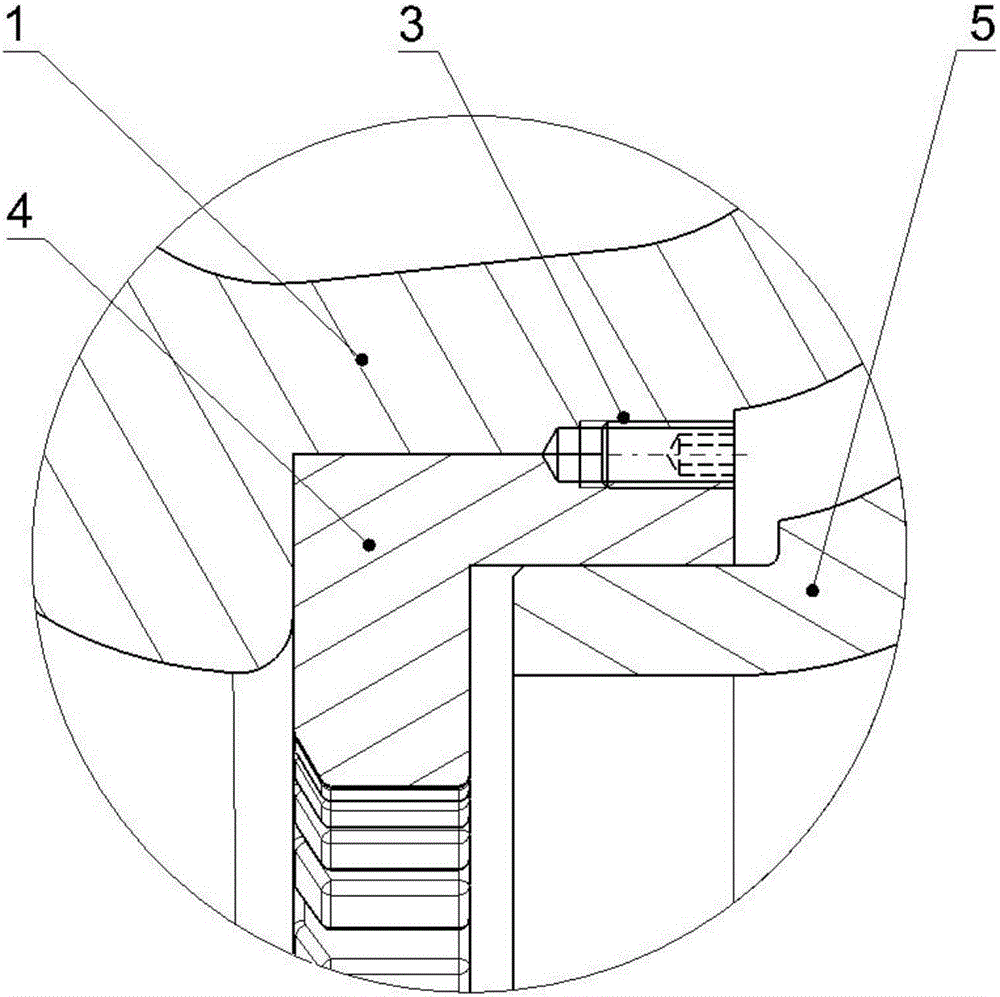

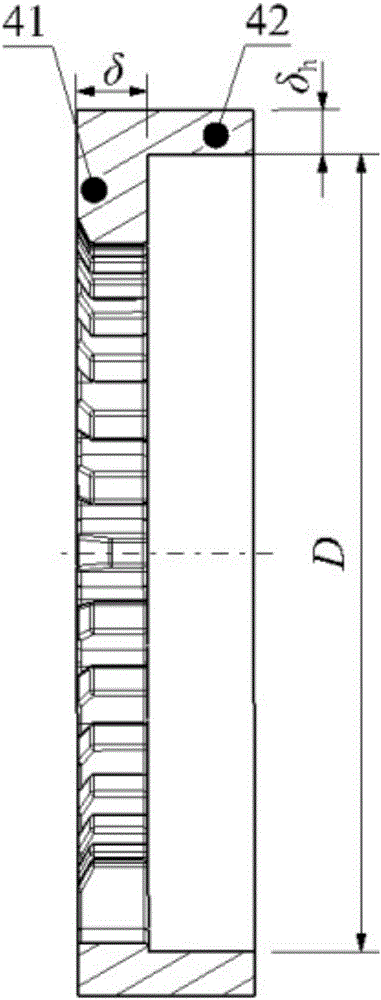

[0033] refer to Figure 1 to Figure 3b , a self-priming centrifugal pump with high cavitation resistance, including a pump body 1, a pump cover 8, a bearing frame 9 and an impeller 5 mounted on a pump shaft 10, a bearing is provided on the bearing frame 9, and a pump shaft 10 is arranged inside the bearing, There is a pump cover 8 on one side of the bearing frame 9; there are three cavities on the pump body 1, which are respectively the water absorption chamber 2, the liquid storage chamber 6 and the pressure water chamber 7, the liquid storage chamber 6 and the water absorption chamber 2, and the pressure water chamber 7 In communication, a rectification ring 4 is installed at the outlet of the water absorption chamber 2, and the rectification ring 4 includes a zigzag annular baffle 41 on the front side that can suppress the backflow of the axial surface inlet and secondary flow in the section and a rear side Ring sleeve 42; the inner circumference of the front side of the re...

Embodiment 2

[0044] This embodiment proposes a self-priming centrifugal pump with high cavitation resistance, wherein the seam-riding screw 3 is made of stainless steel to prevent it from being disassembled due to erosion or corrosion.

[0045] Such as Figure 3a with 3b Shown, impeller inlet diameter D 0 = 80mm, the axial thickness of the sawtooth baffle δ = 8mm, the thickness of the ring sleeve δ h = 5mm. This embodiment selects k=1 / 16, that is, the sawtooth height h=1 / 16D 0 , the lengthened tooth height is 2 times h, that is, 2h=1 / 8D 0 , the circumferential width of the sawtooth and the gap correspond to the central angle θ=ω=6°. The gap between the two sides of the sawtooth at the top of the sawtooth encryption area is the smallest ω 1 =1°, and then gradually transition to the non-encrypted area, and the transition gap is ω 2 =1.5°, ω 3 =2.5°, ω 4 =3.5°, ω 5 = 4.5° and ω 6 =5°, thus finally determine the number of sawtooth n=33, and the structure of the entire rectifying rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com