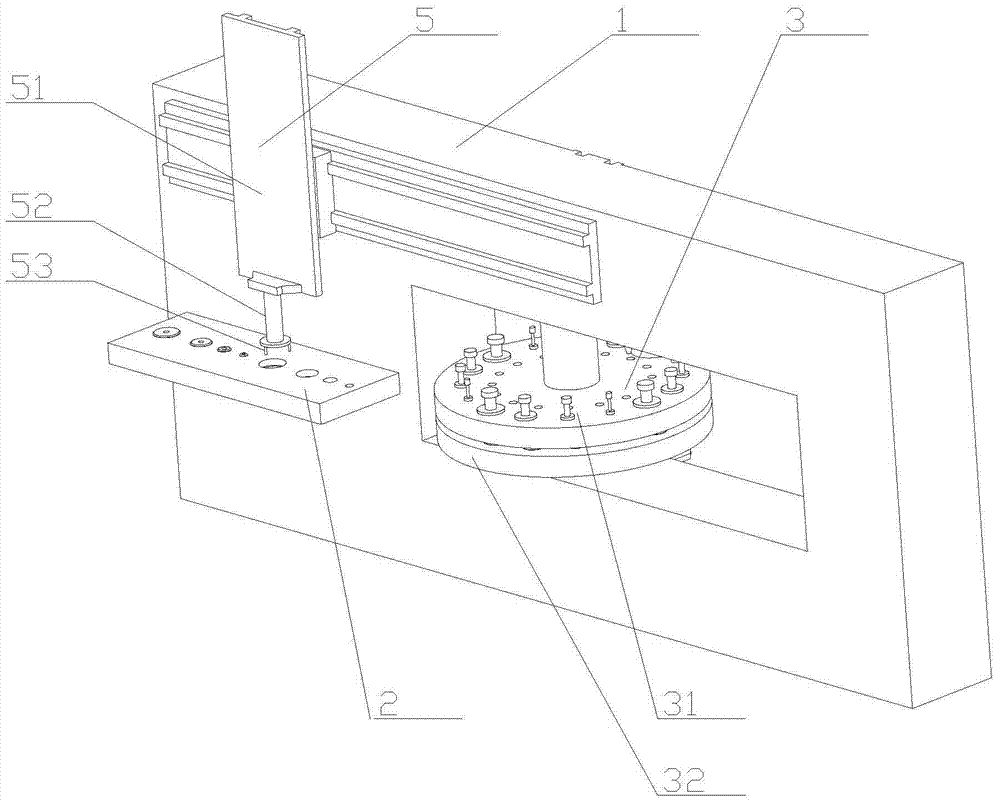

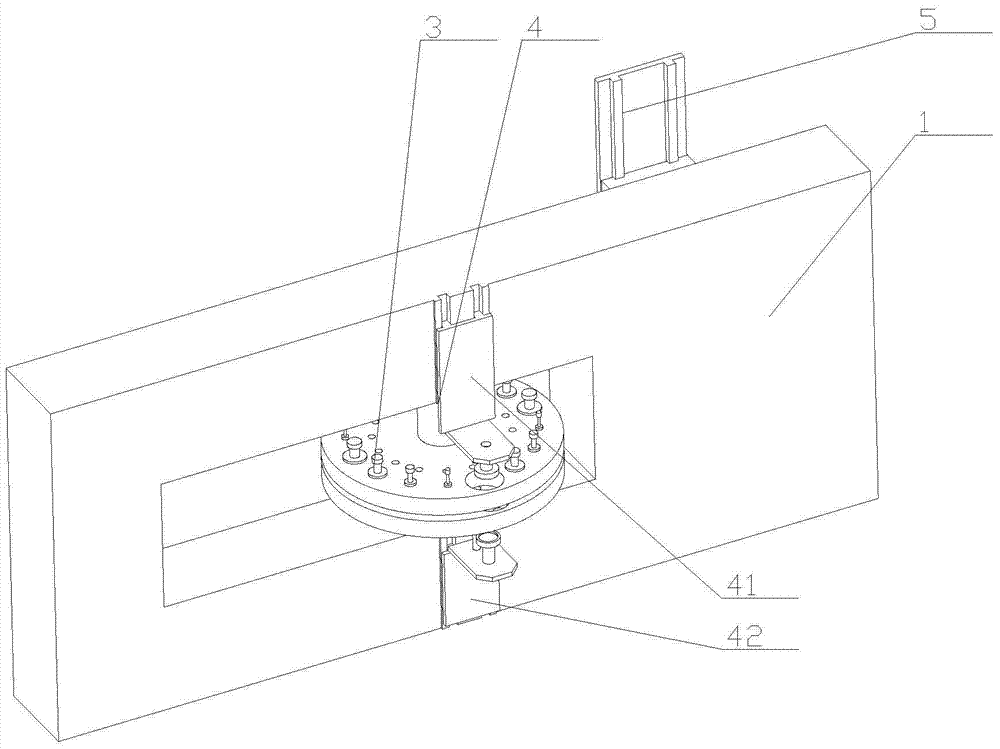

A CNC turret punch press

A CNC turret punch and turntable technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to identify and judge, insignificant changes in punching force, and inability to truly reflect mold wear conditions, etc. Achieving compact and easy-to-implement, large jaw travel range and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: The bottom surface of the horizontal part 1 4122 is fixedly connected with a positioning pin 1 4123, and one side of the upper reserved hole is provided with a pin hole 1 matching with the positioning pin 1, and the horizontal part 2 4222 A positioning pin 2 4223 is also fixedly connected to the top surface of the top surface, and one side of the lower reserved hole is provided with a pin hole 2 adapted to the positioning pin 2.

Embodiment 2

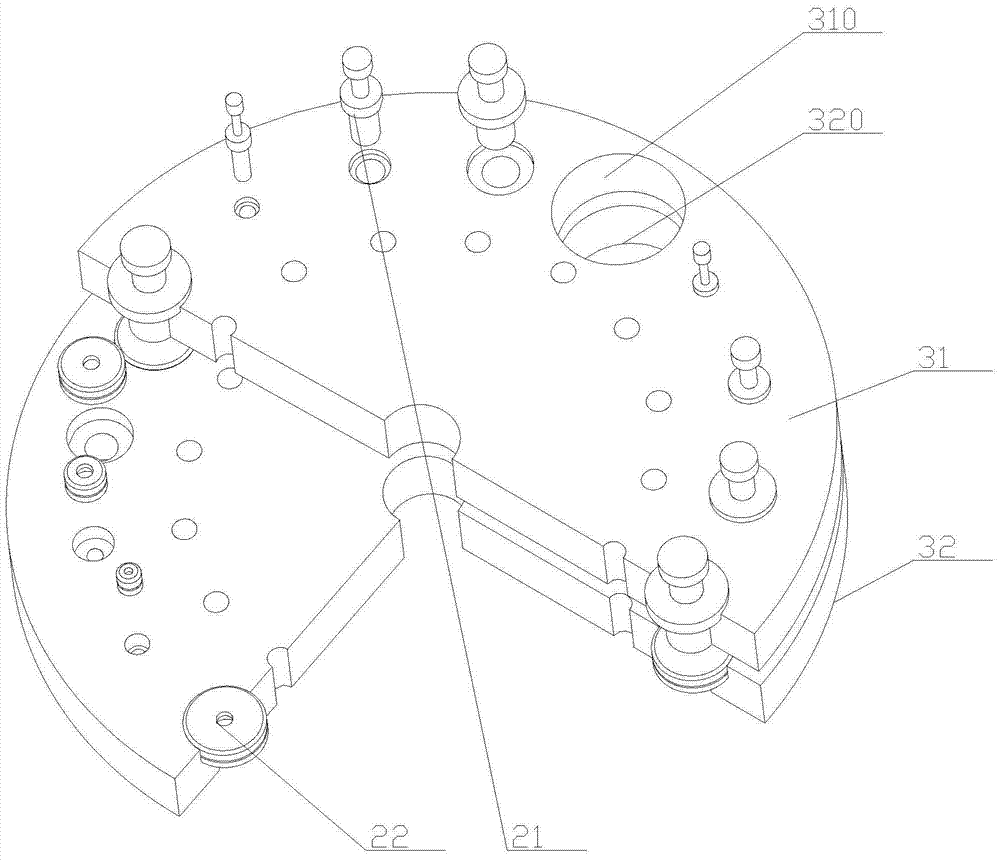

[0063] Embodiment 2: The bottom surface of the horizontal part 1 4122 is also fixedly connected with a positioning sleeve 1, and the positioning sleeve 1 is empty to cover the vision probe 1 411, and the bottom surface of the positioning sleeve 1 is higher than that of the vision probe 1 411. bottom surface, and the outer diameter of positioning sleeve one is smaller than the inner diameter of the upper reserved hole 310;

[0064] The bottom surface of the horizontal part 2 4222 is also fixedly connected with a positioning sleeve 2, the positioning sleeve 2 is empty for the vision probe 2 421, and the top surface of the positioning sleeve 2 is lower than the top surface of the vision probe 2 421 , and the outer diameter of the second positioning sleeve is smaller than the inner diameter of the lower reserved hole 320 . Therefore, while being convenient for positioning, it also has the following characteristics: first, it avoids blocking the visual probe 1 or the visual probe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com