Method for searching equipment wear by using fluorescent indicator as indicator

A fluorescent indicator, indicator technology, applied in the direction of fluorescence/phosphorescence, material analysis by optical means, measurement device, etc., can solve slow wear, one is uncontrollable, such as entering foreign objects or between transmission mechanisms Abnormal collision, inability to eliminate the impact of wear debris product quality, inability to quickly locate minor wear and other problems, to achieve high promotion and application value, eliminate quality impact, eliminate product static electricity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for finding equipment wear using a fluorescent indicator as an indicator, characterized in that it comprises the following specific steps:

[0028] S1. Prepare the fluorescent indicator and put it into the spraying tool;

[0029] S2. The equipment stops running and power off;

[0030] S3. Evenly spray a layer of fluorescent indicator on the area that may be worn out in the equipment, and after it dries out, use an ultraviolet light to check whether there is any leakage, and take pictures or videos for subsequent comparison;

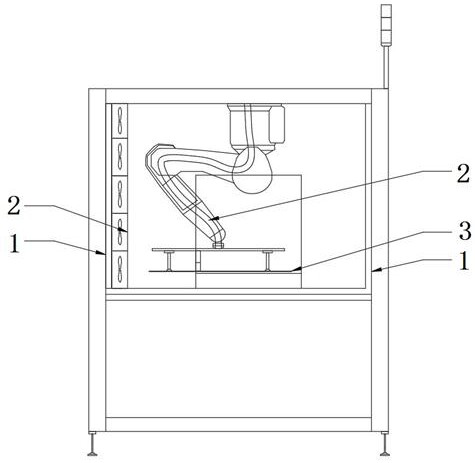

[0031] S4. Install brand-new filter cotton 1 in the corresponding area where the fluorescent indicator is sprayed. During equipment maintenance or inspection, first check whether there is a fluorescent reaction on the filter cotton. If there is a fluorescent reaction, check the corresponding position of the equipment through the position of the fluorescent reaction. of wear and tear.

[0032] The present invention can realize visual equi...

Embodiment 2

[0045]This embodiment provides a method of using a fluorescent indicator as an indicator to find equipment wear that is the same as in Example 1. The difference is that the fluorescent indicator includes the following components in parts by weight: SrO 40-55, B2O3 21, P2O5 4, Gd2O3 1.5, MgO 27, La2O3 1.7, water-based polyurethane adhesive 85.

[0046] Further, the preparation method of the fluorescent indicator is as follows: Weigh the raw materials according to the ratio of parts by weight, grind and stir SrO, B2O3, P2O5, Gd2O3, MgO, La2O3 evenly, and place them in a silicon carbide rod electric furnace at 750°C at high temperature Burn for 2.2 hours, after cooling, take out the pulverized ball and pass through a 350-mesh sieve to obtain ultraviolet fluorescent powder. Mix the ultraviolet fluorescent powder into water-based polyurethane adhesive and disperse evenly at high speed to obtain a fluorescent indicator.

[0047] In the present invention, the phosphor powder with str...

Embodiment 3

[0049] This embodiment provides a method of using a fluorescent indicator as an indicator to find equipment wear that is the same as in Example 1. The difference is that the fluorescent indicator includes the following components in parts by weight: SrO 52, B2O3 35, P2O5 7 , Gd2O34, MgO 31, La2O3 2.2, water-based polyurethane adhesive 105.

[0050] Further, the preparation method of the fluorescent indicator is as follows: weigh the raw materials according to the ratio of parts by weight, grind and stir SrO, B2O3, P2O5, Gd2O3, MgO, and La2O3 evenly, and place them in a silicon carbide rod electric furnace at 1000°C at high temperature Burn for 2.8 hours, after cooling, take out the pulverized ball and pass through a 350-mesh sieve to obtain ultraviolet fluorescent powder. Mix the ultraviolet fluorescent powder into water-based polyurethane adhesive and disperse evenly at high speed to obtain a fluorescent indicator.

[0051] In the present invention, the phosphor powder with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com