A wear test device and test method for a valve-valve guide friction pair

A valve guide and testing device technology, which is applied to measuring devices, engine testing, and mechanical component testing, etc., can solve the problems of insufficient consideration of actual wear patterns, lengthy cycles, and complicated testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

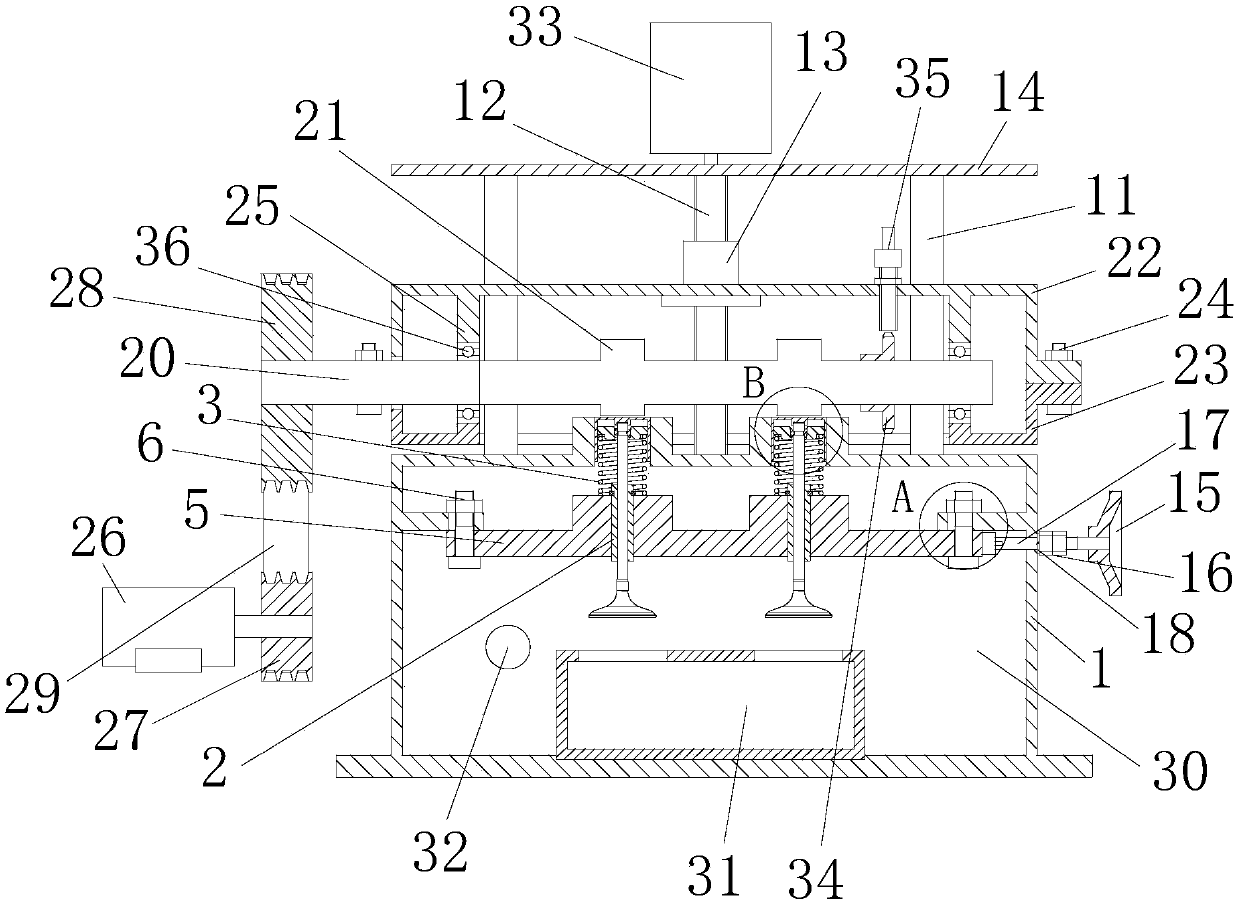

[0036] A wear test device for a valve-valve guide friction pair, comprising a frame 1, a valve guide 2, a guide force device, a valve return spring 3, a valve clearance adjustment device and a valve driving device for driving the valve to move, the valve clearance adjustment The device is connected with the valve driving device for adjusting the valve clearance 4;

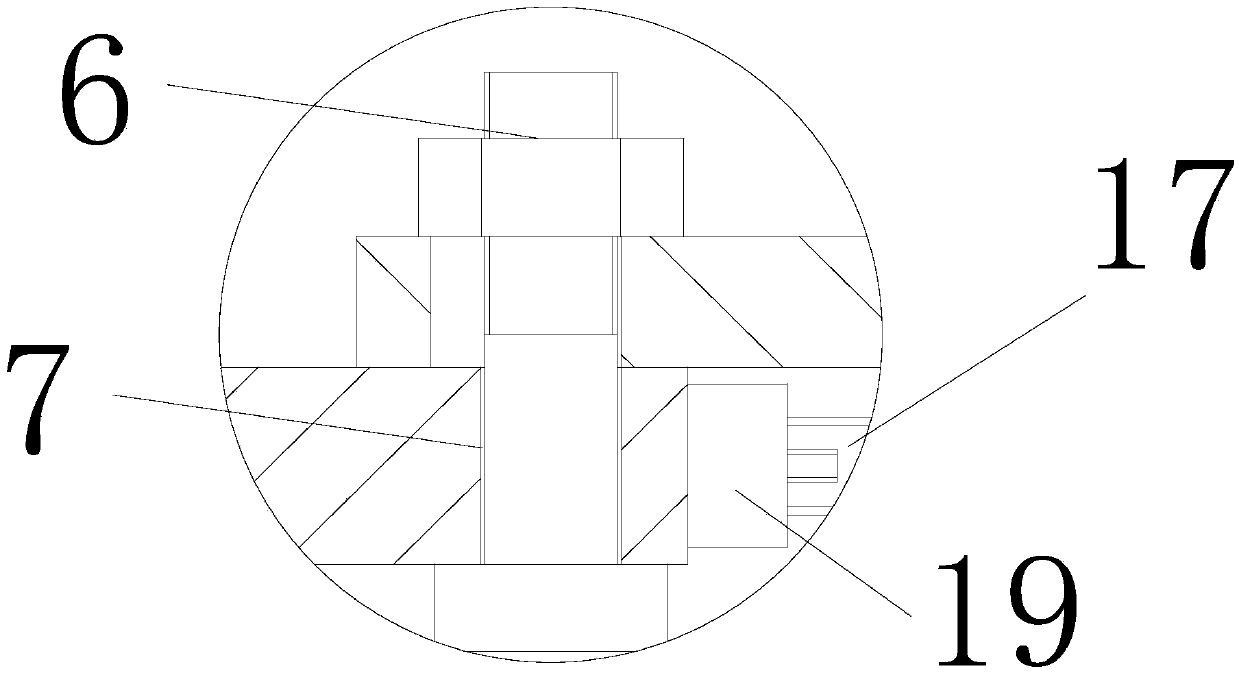

[0037] The conduit booster device includes a booster seat 5, a locking bolt 6 and a force applying mechanism for pushing the booster seat. A conduit installation hole is opened on the booster seat, and the valve guide is installed in the conduit installation hole. Adjustment holes are provided, and the locking bolts pass through the adjustment holes respectively and are fixed to the frame, and an adjustment space 7 is formed between the adjustment holes and the locking bolts;

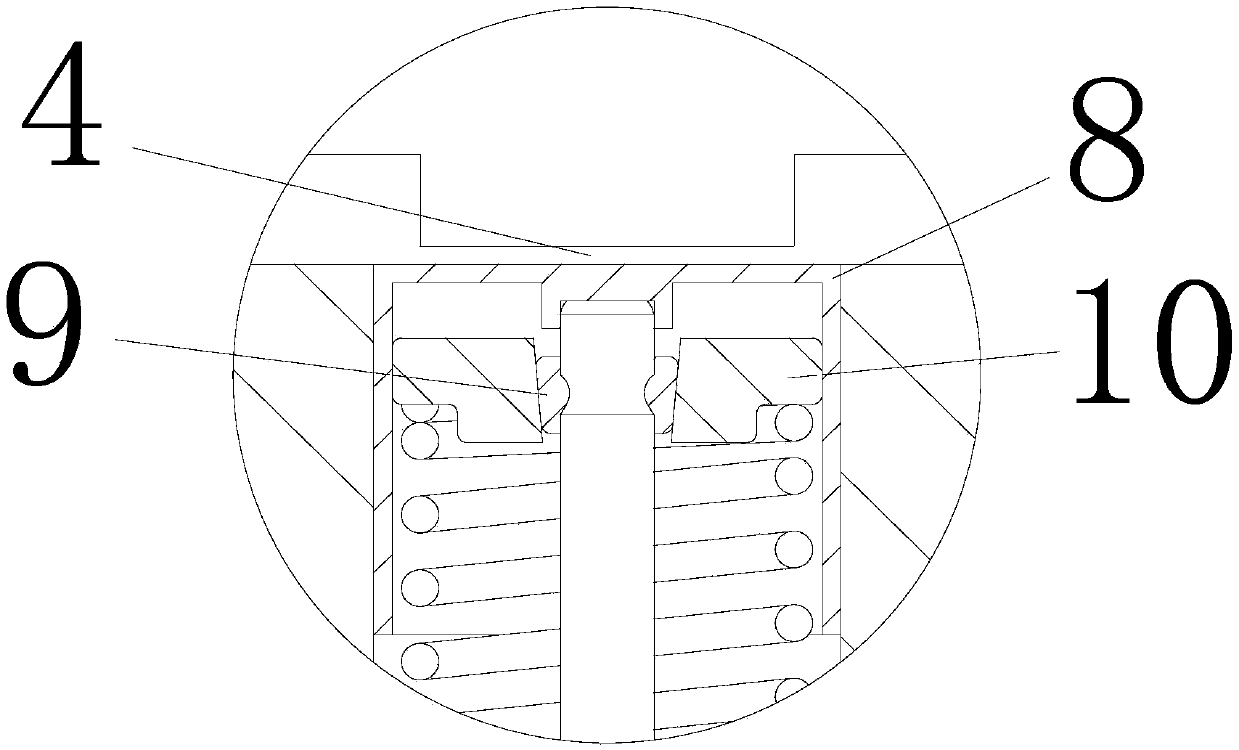

[0038] The middle part of the valve stem of the valve is passed through the valve guide, and the two ends of the valve return spring are re...

Embodiment 2

[0062] A wear test method of the valve-valve guide friction pair, a method of controlling the horizontal loading force: the force application mechanism pushes the force-added seat, and the force-added seat moves within the range of the adjustment space, and the valve is controlled by controlling the thrust applied by the force-apply mechanism the contact pressure between the guide tube and the valve stem of the valve;

[0063] The method of adjusting the valve clearance: the screw drive mechanism drives the screw to rotate, drives the screw nut to drive the drive device mounting frame to move up or down, and drives the camshaft to move away from or close to the valve when the drive device mounting frame moves, thereby adjusting the size of the valve clearance ;

[0064] When testing the influence of the horizontal loading force on the amount of wear, adjust the valve clearance to the set value; then, make the force applying mechanism apply the set horizontal loading force to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com