A Wear Test Device for Cam-Tappet Friction Pair

A testing device and friction pair technology, which can be used in measuring devices, testing wear resistance, instruments, etc., and can solve the problems of costing a lot of manpower and material resources, unsatisfactory experimental results, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

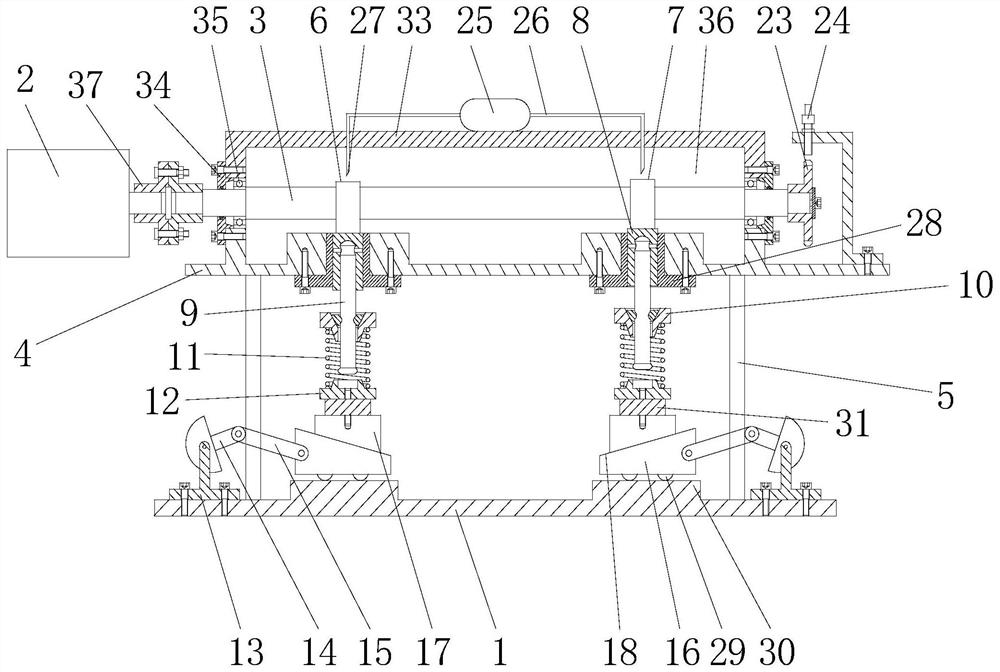

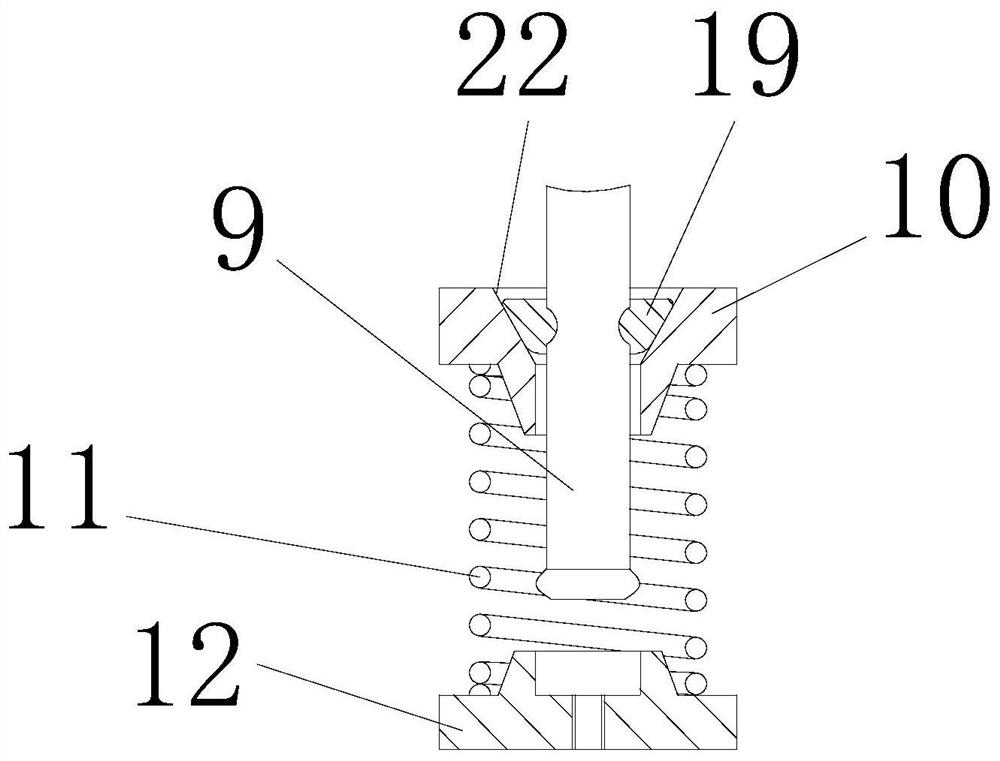

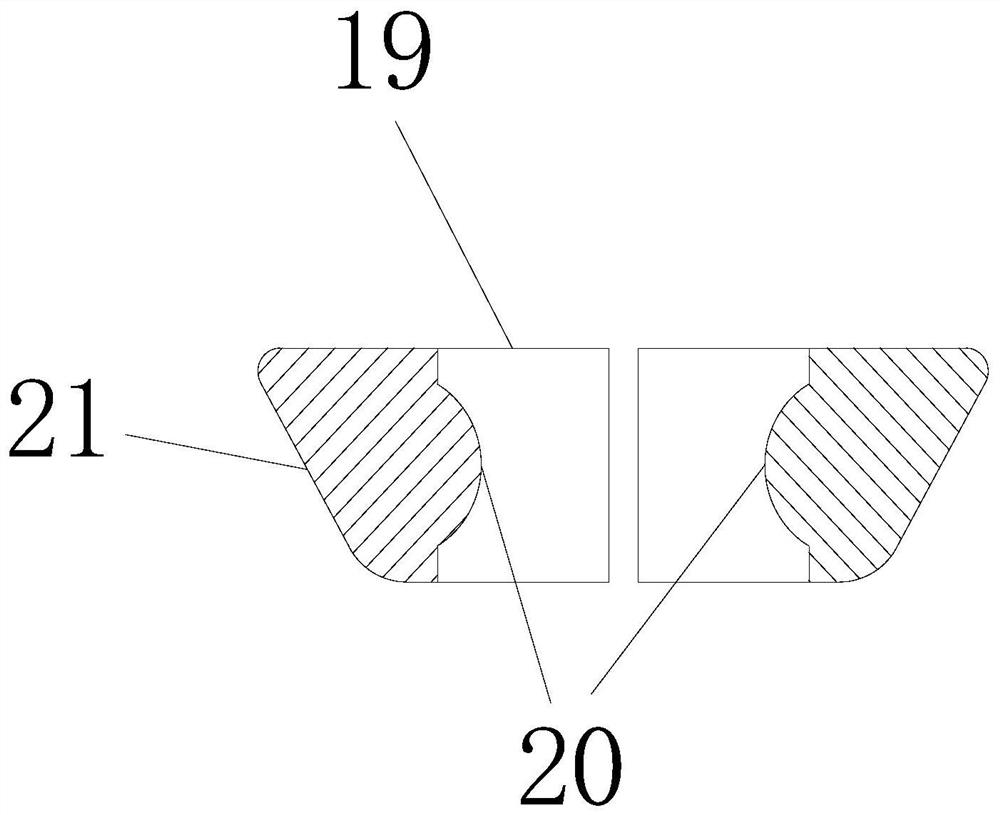

[0027] A wear test device for a cam-tappet friction pair, comprising a machine base, a motor, a camshaft, a cam lower frame, a support rod and a cam pushing mechanism, the cam lower frame is fixed on the machine base through a support rod, the motor and the camshaft Connection, the camshaft has an intake cam and an exhaust cam (the intake cam and the exhaust cam are referred to as cams for short), the camshaft is installed on the lower end frame of the cam, and the cam pushing mechanism includes the intake wheel pushing mechanism and the exhaust wheel The push mechanism, the intake wheel push mechanism and the exhaust wheel push mechanism both include a tappet, a push rod, an upper spring seat, a loading spring, a lower spring seat and a loading force adjustment mechanism, and the tappet is slidably connected to the lower end frame of the cam and the two tappets are respectively set corresponding to the intake cam and the exhaust cam, the upper part of the push rod is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com