Combustion control method for copper refining and control system

A control method and control system technology, applied in the field of copper refining, can solve problems such as prone to explosion, and achieve the effects of increasing content, convenient control, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

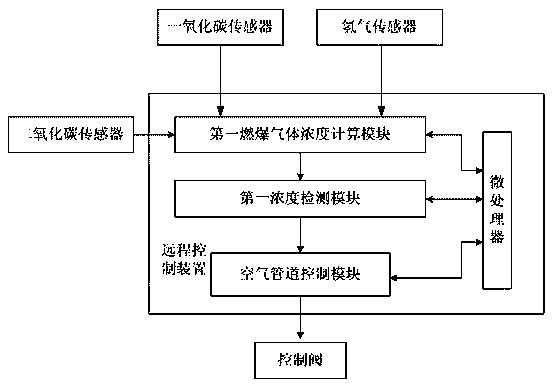

Embodiment 1

[0032] Combustion control method used in copper refining. During the whole refining process, pure oxygen is fed to burn natural gas. During the reduction process, natural gas is burned according to the concentration of hydrogen, carbon dioxide and carbon monoxide in the underground flue and air is also fed in ( At this time, simultaneously feed air and pure oxygen to burn the natural gas), specifically: when the concentration sum of the three gases of hydrogen, carbon dioxide, and carbon monoxide is equal to or higher than the lower explosion limit, open the air pipeline to feed air to burn the natural gas, When the concentrations of hydrogen, carbon dioxide, and carbon monoxide are lower than the lower explosion limit, close the air pipeline and only feed pure oxygen to burn natural gas. Both air and pure oxygen are combustion-supporting gases.

[0033] The lower limit of explosion described in the present invention refers to the minimum concentration at which the mixed gas c...

Embodiment 2

[0079] On the basis of Embodiment 1, the remote control device is further improved in this embodiment:

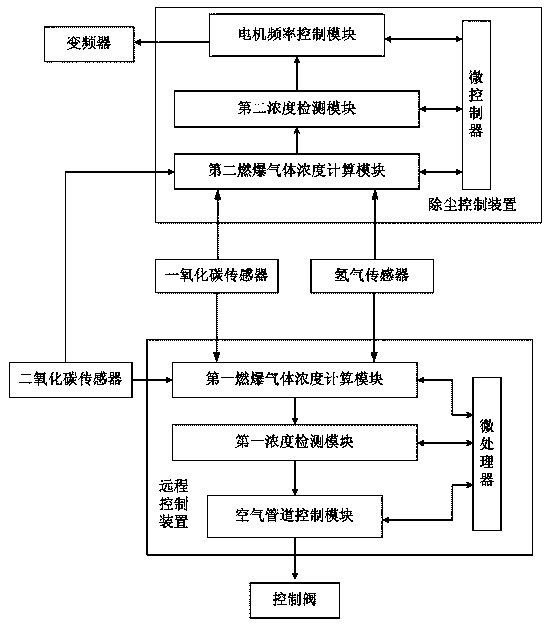

[0080] Such as Figure 4 As shown, the first deflagration gas concentration calculation module includes an adder A1 and an adder A2, and the output terminals of two of the sensors in the hydrogen sensor, the carbon monoxide sensor, and the carbon dioxide sensor are respectively connected to an input end of the adder A1 , the output end of another sensor is connected to one input end of the adder A2; the other input end of the adder A2 is connected to the output end of the adder A1, and the output end of the adder A2 is the first explosion gas concentration calculation module output terminal. In this embodiment, the hydrogen sensor and the carbon monoxide sensor are connected to the two input terminals of the adder A1, so that the adder A1 performs a summation calculation on the hydrogen concentration Vh2 and the carbon monoxide concentration Vco, and the adder A2 compares ...

Embodiment 3

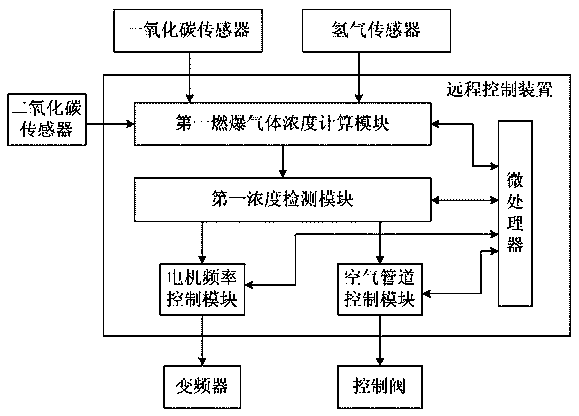

[0090] Generally, a dust removal device is provided at the outlet of the underground flue, and the dust removal device is provided with a working power provided by a motor, and the frequency of the motor of the dust removal device is controlled by a frequency converter: in this embodiment, on the basis of Embodiment 1 or Embodiment 2 , the remote control device is also improved as follows:

[0091] Such as figure 2 As shown, the remote control device also includes a motor frequency control module for controlling the frequency converter, the input terminal of the motor frequency control module is connected to the output terminal of the first concentration detection module, and the output terminal of the motor frequency control module is connected to the frequency converter.

[0092] In this embodiment, the motor frequency control module is a switching circuit, such as Figure 4 As shown, the motor frequency control module adopts a triode switching circuit, including a triode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com